Microcapsule for textile after-finishing as well as preparation method and application thereof

A microcapsule and post-finishing technology, which is applied in the field of textile finishing agents, can solve problems such as poor thermal stability, insufficient affinity, and easy volatility, and achieve good mechanical strength, strong mosquito repellent effect, and good affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

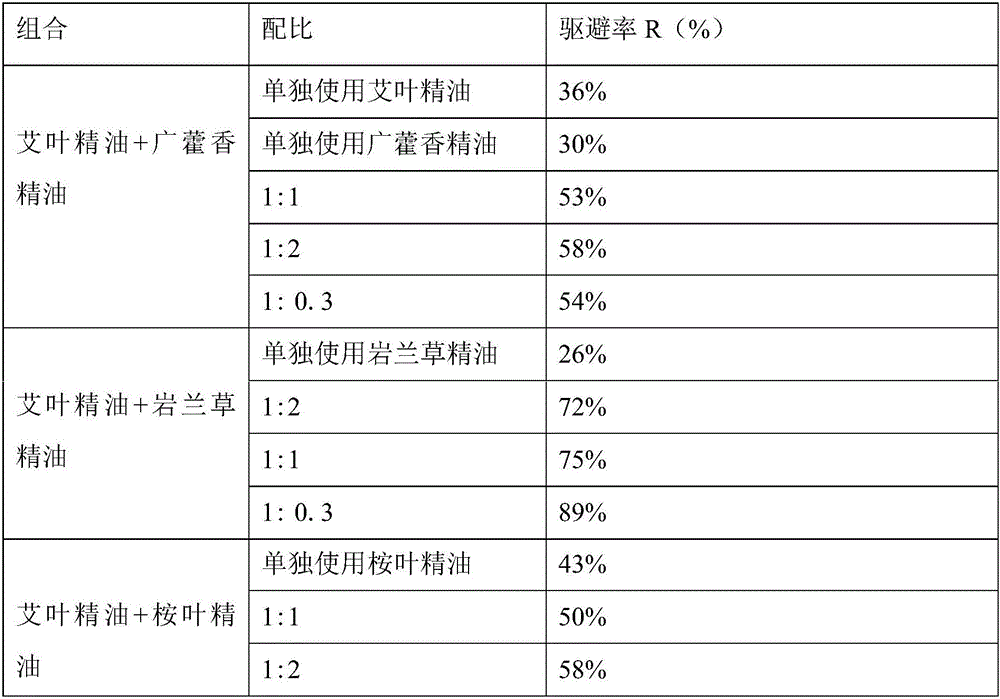

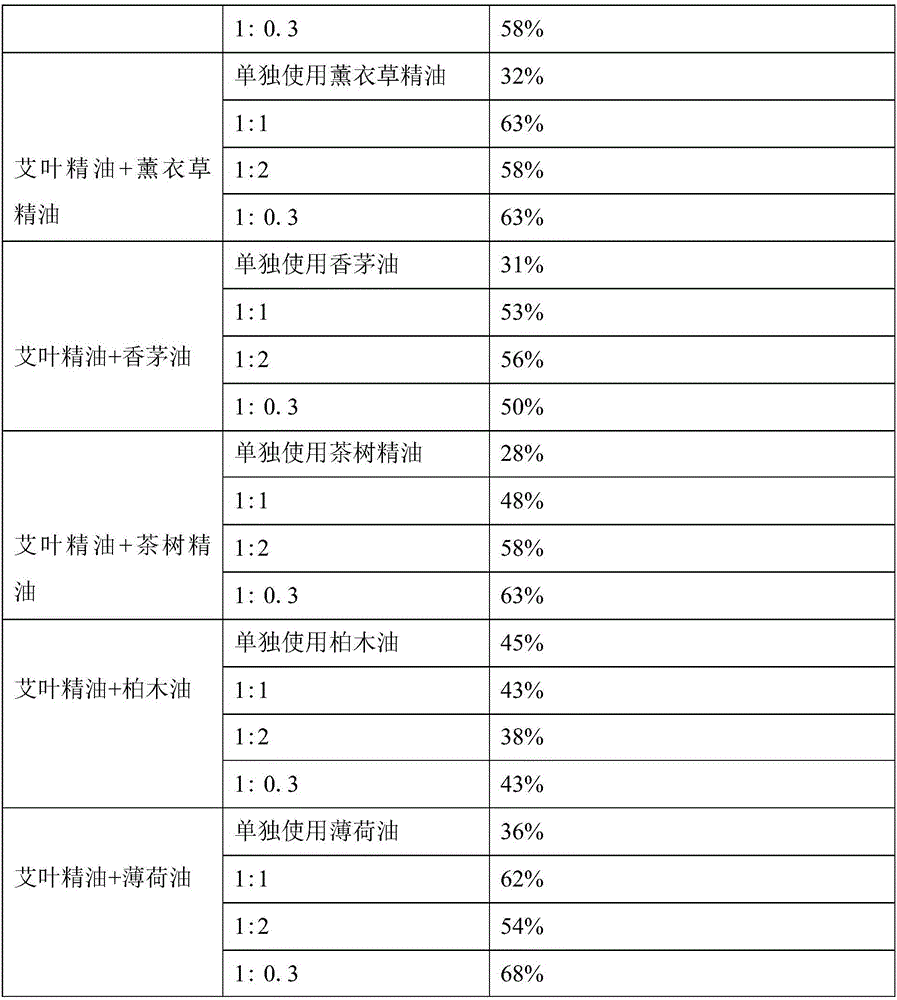

[0035] Embodiment 1, the mosquito repellent effect that contains the microcapsule of different plant essential oil combination

[0036] Add 3g of microcapsules containing the following combinations of different plant essential oils per 1Kg of textiles, use polyacrylamide as the binder, and finish the textiles through a finishing process of dipping and rolling. According to the repellent method in GB / T30126-2013 The textiles finished with microcapsules were subjected to a mosquito repellent test, and the test results are shown in Table 1 below.

[0037] Table 1 Test results

[0038]

[0039]

[0040] It can be seen from the above table 1 that the textiles finished with microcapsules prepared by the combination of mugwort essential oil and vetiver essential oil have a strong repelling effect on mosquitoes, and the repellent rate can reach more than 70%, especially after the compounding of 1:0.3 The textiles finished with the obtained microcapsules have the highest repelle...

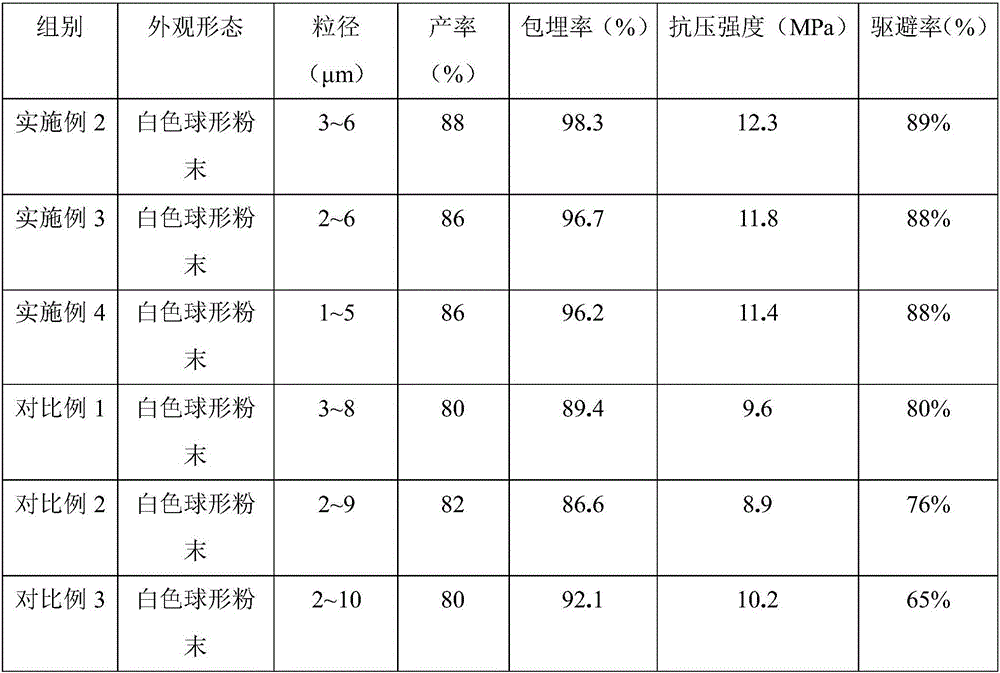

Embodiment 2

[0042] Embodiment 2, a kind of microcapsules for finishing after weaving

[0043] The microcapsules described in Example 2 of the present invention consist of a core material and a capsule wall in a weight ratio of 0.3:1, the core material includes 15 parts of plant essential oils and 0.6 parts of L-methionyl glycine hydrochloride, and the capsule wall It is prepared from octenyl succinic esterified starch, nano-microcrystalline cellulose and sodium caseinate in a weight ratio of 1:0.2:0.6, and the plant essential oil is composed of Artemisia argyi essential oil and vetiver essential oil in a weight ratio of 1:0.3 composition.

[0044] Preparation:

[0045] A) dissolving octenyl succinate starch in purified water to prepare an aqueous solution of octenyl succinate starch with a mass fraction of 2.0%;

[0046]B) dissolving sodium caseinate in water to prepare an aqueous solution of sodium caseinate with a mass fraction of 6.0%, dissolving nanocrystalline cellulose in the aque...

Embodiment 3

[0050] Embodiment 3, a kind of microcapsules for finishing after weaving

[0051] The microcapsules described in Example 3 of the present invention are composed of a core material and a capsule wall in a weight ratio of 0.2:1, the core material includes 10 parts of plant essential oils and 0.2 parts of L-methionyl glycine hydrochloride, and the capsule wall It is prepared from octenyl succinic esterified starch, nano-microcrystalline cellulose and sodium casein at a weight ratio of 1:0.1:0.3, and the plant essential oil is made of Artemisia argyi essential oil and vetiver essential oil at a weight ratio of 1:0.2 composition.

[0052] The preparation method is as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com