Manufacturing method of odorless electrostatic adsorption multifunctional spunlaced industrial wiping rag

A production method, odorless technology, applied in the direction of thorn pattern, liquid/gas/vapor fiber/sliver/roving treatment, heating/cooling fabric, etc., can solve the problem of unsatisfactory effect and achieve the effect of high-efficiency adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

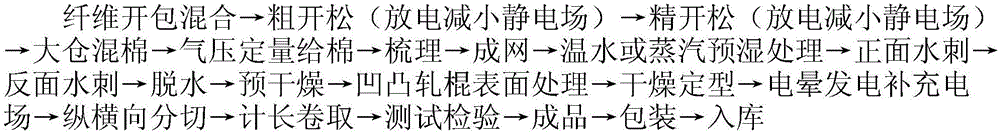

[0016] A method for producing an odorless multifunctional spunlace industrial wiping cloth with static electricity, which is characterized in that it comprises the following steps,

[0017] Step 1. Take the odorless and electrostatically attached polypropylene short fiber as the raw material. The length of the odorless and electrostatically attached polypropylene short fiber is 38mm~45mm, and the fiber fineness is 1.67dtex~2.78dtex; the fiber passes through the coarse gear roller of the opener Coarse opening is carried out, and the fibers after coarse opening are finely opened by fine-toothed rollers to obtain loose fibers with reduced electrostatic field; the loose fibers enter the large warehouse cotton blender through the conveying pipeline for fiber mixing;

[0018] Step 2. The fibers mixed by the Dacang cotton blender in the step 1 are transported to the air pressure metering machine through air flow, and the mixed fibers are transported to the carding machine by pressure....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com