Preparation method of tritium permeation resisting electrical insulating coating layer on surface of vanadium alloy and product prepared through preparation method

A technology of vanadium alloy and electrical insulation, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of material plasticity reduction, tritium radioactive pollution, brittle fracture, etc., and achieve compact structure, good bonding, The effect of guaranteeing the self-sustainability of tritium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

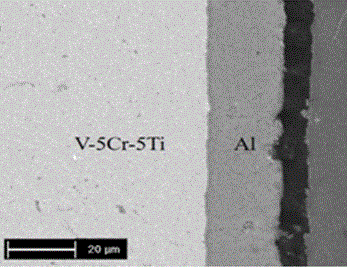

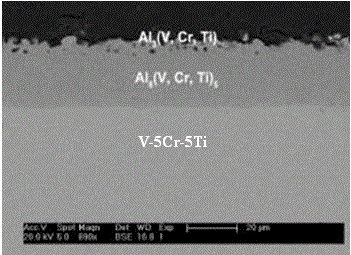

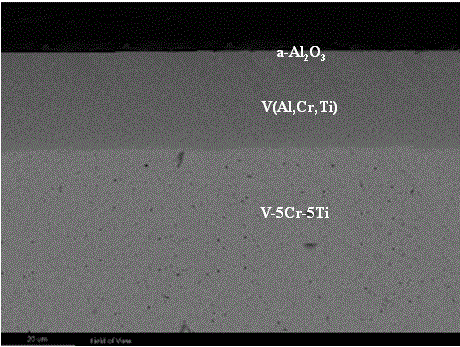

[0049] Embodiment 1 prepares coating on V-5Cr-5Ti surface

[0050] The specific operation process of this embodiment is as follows.

[0051] 1) Take a V-5Cr-5Ti sheet with a length and width of 20 mm and a thickness of 2 mm. After degreasing by conventional methods, put the sample into AlCl in an argon-protected glove box. 3 -EMIC (molar ratio 2:1) solution (ie, ionic liquid), anodized at room temperature 25°C, potential 1.25V (Vs.Al), activated for 60min to remove the oxide film. Among them, when the vanadium alloy is activated, the vanadium alloy is used as the anode, the pure aluminum is used as the cathode, the anode and the cathode are continuously washed with ionic liquid, and the constant potential anode activation treatment is performed to remove the oxide film on the surface of the vanadium alloy.

[0052] 2) Put the V-5Cr-5Ti alloy after the anodizing treatment in step 1 into AlCl 3 -EMIC (molar ratio 2:1) solution, at room temperature 25°C, for aluminum plating. ...

Embodiment 2

[0056] Embodiment 2 prepares coating on V-4Cr4Ti surface

[0057] The specific operation process of this embodiment is as follows.

[0058] 1) Take a V-4Cr-4Ti sheet with a length and width of 20mm and a thickness of 2mm. After degreasing by conventional methods, put the sample into the AlCl 3 -EMIC (molar ratio 2:1) solution, anodized at room temperature 25°C, potential 1.25V (Vs.Al), activated for 30min to remove the oxide film. Among them, when the vanadium alloy is activated, the vanadium alloy is used as the anode, the pure aluminum is used as the cathode, the anode and the cathode are continuously washed with ionic liquid, and the constant potential anode activation treatment is performed to remove the oxide film on the surface of the vanadium alloy.

[0059] 2) Put the anodized sample in step 1 into AlCl 3 -EMIC (molar ratio 2:1) solution, at room temperature, for aluminum plating. During aluminum plating, pure aluminum is used as the anode, and the vanadium alloy pr...

Embodiment 3

[0063] Embodiment 3 prepares coating on columnar V-5Cr-5Ti surface

[0064] The specific operation process of this embodiment is as follows.

[0065] 1) Take a columnar V-5Cr-5Ti with a diameter of 20mm and a height of 50mm. After degreasing by conventional methods, put the sample into AlCl in an argon protective glove box. 3 - EMIC (molar ratio 2:1) solution, anodized at room temperature 25°C, potential 1.25V (Vs.Al), activated for 60min to remove the oxide film. Among them, when the vanadium alloy is activated, the vanadium alloy is used as the anode, the pure aluminum is used as the cathode, the anode and the cathode are continuously washed with ionic liquid, and the constant potential anode activation treatment is performed to remove the oxide film on the surface of the vanadium alloy.

[0066] 2) Put the anodized sample in step 1 into AlCl 3 -EMIC (molar ratio 2:1) solution, at room temperature, for aluminum plating. During aluminum plating, pure aluminum is used as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com