Arsenic removal method in nickel electrolysis mixed acid system

A technology of nickel electrolysis and mixed acid, which is applied in the field of nickel electrolysis, can solve problems such as rising and affecting the economic benefits of electro-nickel, and achieve the effect of stabilizing chemical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

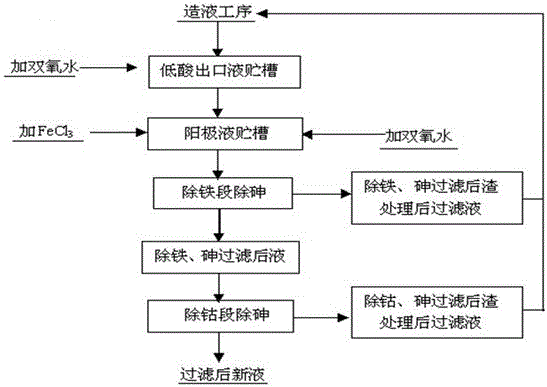

Image

Examples

Embodiment 1

[0018] The nickel electrolytic mixed acid system contains 65g / l of chloride ions, 0.2g / l of iron, and 0.06g / l of arsenic. The method for removing arsenic in the nickel electrolytic mixed acid system includes the following steps:

[0019] A. In the nickel sulfide soluble anode electrolysis process, copper and arsenic are removed by electrochemical deposition in the liquid-making process, and after impurity removal, H is added to the low-acid outlet liquid storage tank for liquid making 2 o 2 solution to oxidize trivalent arsenic in the low-acid outlet liquid of effusion to pentavalent arsenic, which is beneficial to the removal of arsenic, and H 2 o 2 The solution is industrial H with a mass fraction of 30% 2 o 2 The solution diluted 1:1 with water is added in an amount of 0.2% of the mass of the liquid-making low-acid outlet liquid; during the process of electrochemical deposition-induced arsenic removal in the liquid-making process, the anode is a nickel anode plate, and t...

Embodiment 2

[0026] The nickel electrolytic mixed acid system contains 70g / l of chloride ions, 0.3g / l of iron, and 0.03g / l of arsenic. The method for removing arsenic in the nickel electrolytic mixed acid system includes the following steps:

[0027] A. In the nickel sulfide soluble anode electrolysis process, copper and arsenic are removed by electrochemical deposition in the liquid-making process, and after impurity removal, H is added to the low-acid outlet liquid storage tank for liquid making 2 o 2 solution to oxidize trivalent arsenic in the low-acid outlet liquid of effusion to pentavalent arsenic, which is beneficial to the removal of arsenic, and H 2 o 2 The solution is industrial H with a mass fraction of 30% 2 o 2 The solution diluted 1:1 with water is added in an amount of 0.2% of the mass of the liquid-making low-acid outlet liquid; during the process of electrochemical deposition-induced arsenic removal in the liquid-making process, the anode is a nickel anode plate, and t...

Embodiment 3

[0034] The nickel electrolytic mixed acid system contains 68g / l of chloride ions, 0.2g / l of iron, and 0.04g / l of arsenic. The method for removing arsenic in the nickel electrolytic mixed acid system includes the following steps:

[0035] A. In the nickel sulfide soluble anode electrolysis process, copper and arsenic are removed by electrochemical deposition in the liquid-making process, and after impurity removal, H is added to the low-acid outlet liquid storage tank for liquid making 2 o 2 solution to oxidize trivalent arsenic in the low-acid outlet liquid of effusion to pentavalent arsenic, which is beneficial to the removal of arsenic, and H 2 o 2 The solution is industrial H with a mass fraction of 30% 2 o 2 The solution diluted 1:1 with water is added in an amount of 0.2% of the mass of the liquid-making low-acid outlet liquid; during the process of electrochemical deposition-induced arsenic removal in the liquid-making process, the anode is a nickel anode plate, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com