Device and method for extracting uranium from high-density ore pulp

A high-density, ore pulp technology, applied in the field of ion exchange extraction of uranium, can solve the problems of excessive waste water, only 6%, increase water consumption, etc., achieve continuous automatic reverse flow, solve the residual fraction, and reduce the effect of waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

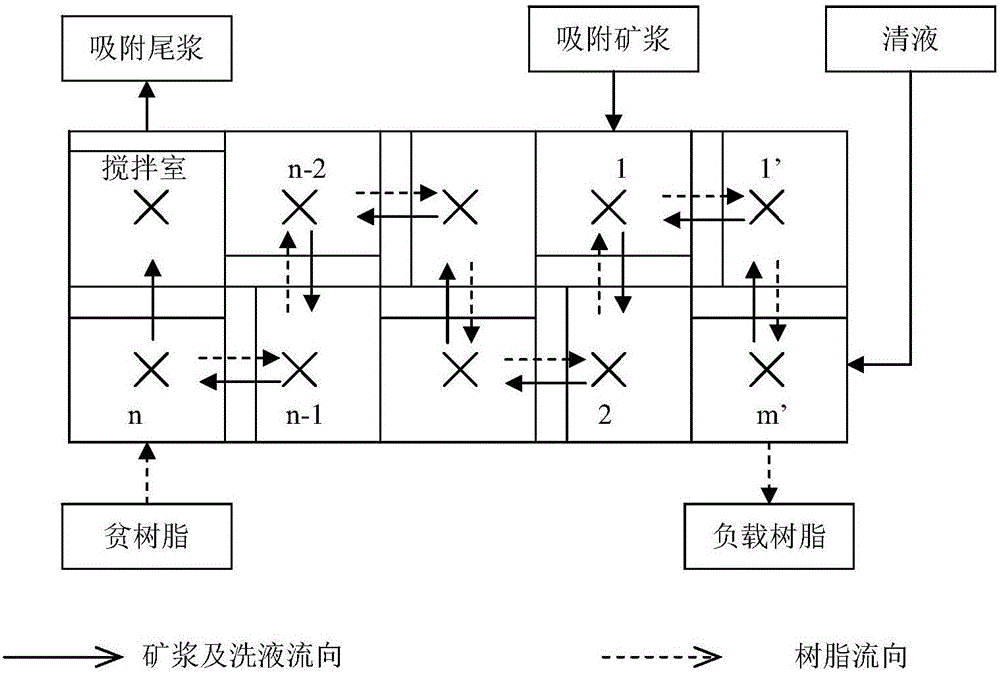

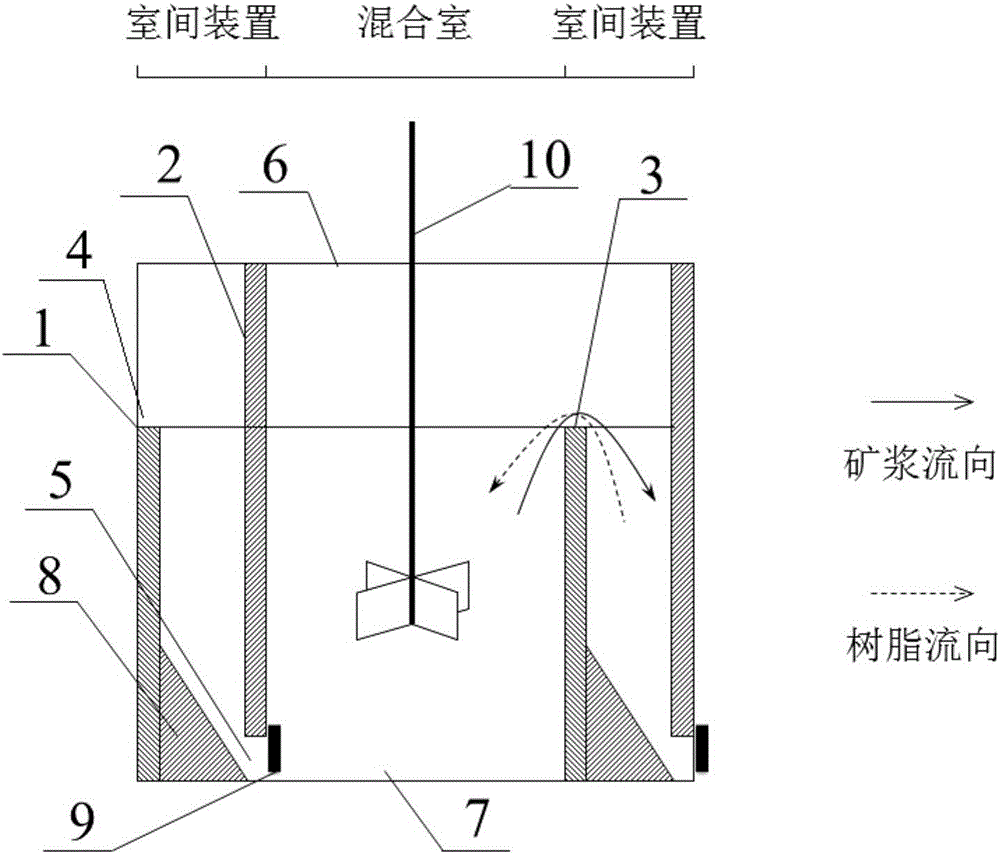

[0034] A device for extracting uranium from high-density ore pulp, the device includes n-stage adsorption units, each stage of adsorption unit includes a mixing chamber and an inter-chamber device, the inter-chamber device of the first-stage adsorption unit is connected with the second-stage adsorption unit The mixing chamber of the second-stage adsorption unit is communicated with the mixing chamber of the third-stage adsorption unit, ..., the inter-chamber device of the n-1th-stage adsorption unit is communicated with the mixing chamber of the n-stage adsorption unit;

[0035] It also includes m' level washing unit, each level washing unit also includes a mixing chamber and an inter-chamber device, the mixing chamber of the 1st level adsorption unit communicates with the inter-chamber device of the 2nd level adsorption unit, and the 2nd level adsorption unit The mixing chamber of the unit communicates with the inter-chamber device of the 3rd stage adsorption unit, ..., the mi...

Embodiment 2

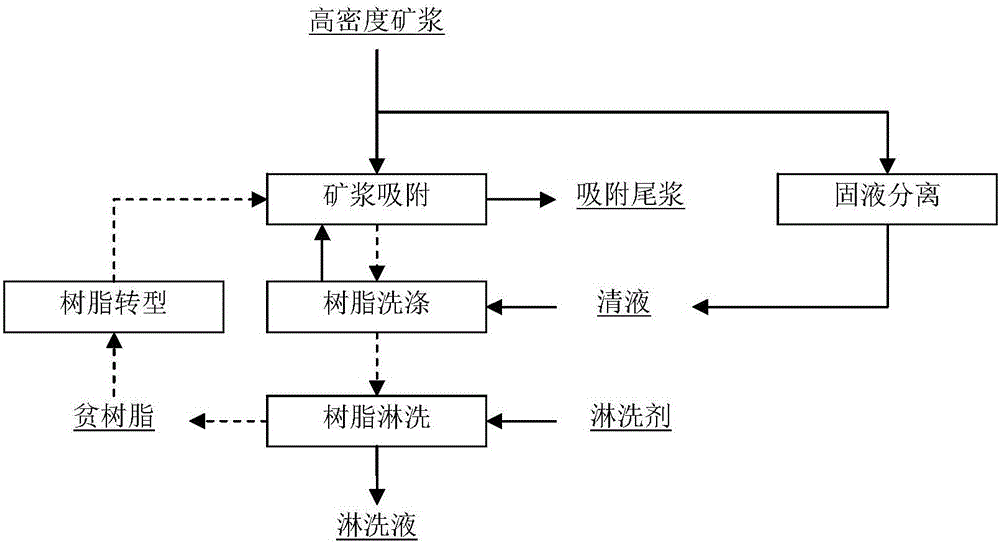

[0051] Using resin to extract uranium from a pulp. The density of the leached pulp solution is 1.5g / L, the uranium content is 1.5g / L, the resin is 201×7 resin, and the wet real density of the resin is 1.10g / cm 3 . The equipment described in the present invention is used for pulp adsorption. The equipment parameters are n=8, m=2, and the side length of the mixing chamber is 300 mm. Pump 95% of the ore slurry into the first-stage adsorption unit of the equipment at a flow rate of 95L / h. Lean resin is fed into the 8th stage adsorption unit at a rate of 5L / h. The 5% ore slurry is filtered to obtain the clear liquid, and the clear liquid is pumped into the 2nd stage washing unit with a flow rate of 5L / h. The washing liquid enters the first stage adsorption unit and merges with the ore pulp in the first stage. In the adsorption unit, the resin enters the mixing chamber from the upper opening and exits the mixing chamber from the lower opening. The pulp enters the mixing chamber...

Embodiment 3

[0053] Using resin to extract uranium from a pulp. The density of the leached pulp solution is 1.3g / L, the uranium content is 1.25g / L, the resin is 201×7 resin, and the wet real density of the resin is 1.10g / cm 3 . The equipment described in the present invention is used for pulp adsorption. Equipment parameters n=10, m=4, side length of the mixing chamber is 500mm. Pump 90% of the ore slurry into the first-stage adsorption unit of the equipment at a flow rate of 450L / h. Lean resin is fed into the 10th stage adsorption unit at a rate of 25L / h. The clear liquid obtained by filtering the 10% ore pulp is pumped into the 2nd stage washing unit with a flow rate of 10L / h. The washing liquid enters the first stage adsorption unit and merges with the ore pulp in the first stage. In the adsorption unit, the resin enters the mixing chamber from the upper opening and exits the mixing chamber from the lower opening. The pulp enters the mixing chamber from the lower opening and exits ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com