Fermentation method of pneumocandin B0

A fermentation method, the technology of pneumocidine, which is applied in the field of microbial fermentation of pneumocidine B0, can solve the problems affecting the quality of caspofungin acetate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

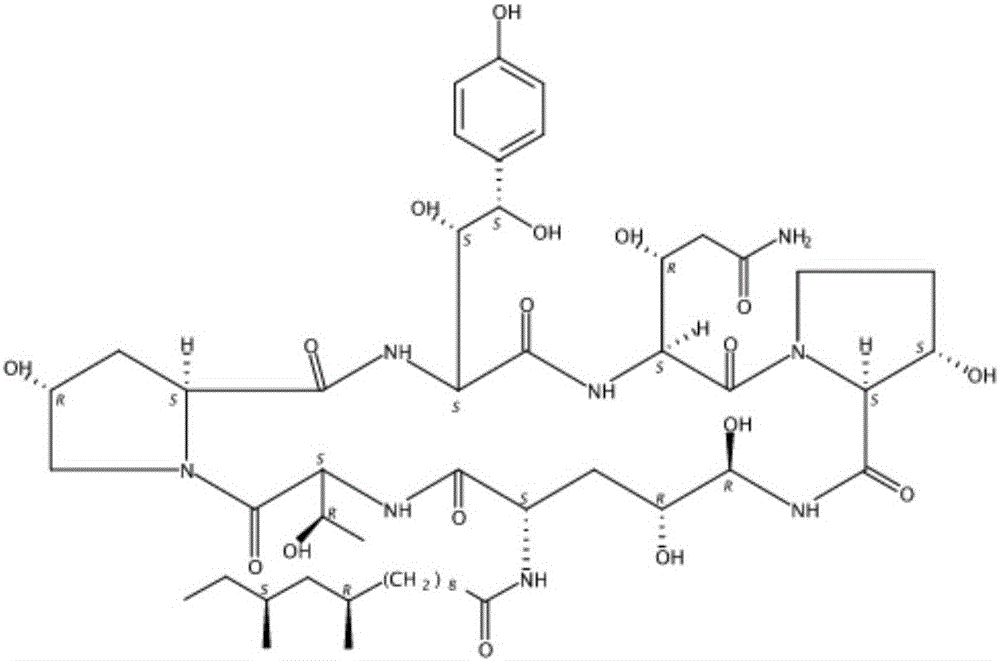

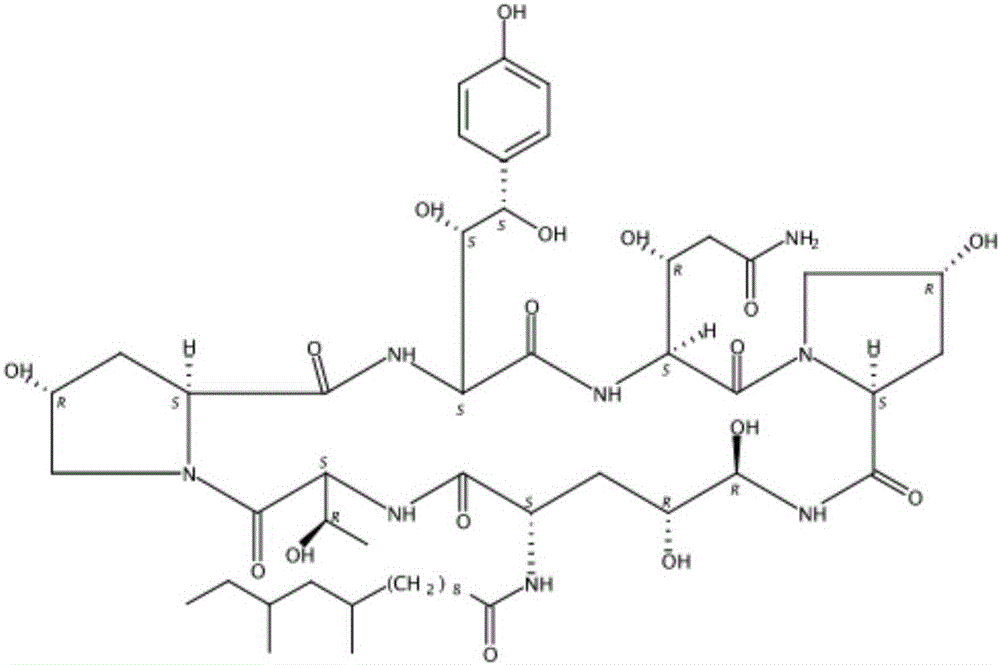

Image

Examples

Embodiment 1

[0017] Fermentation strain: Glarea lozoyensis

[0018] Fermentation medium (wt): lactose 3.0%, threonine 1.0%, yeast powder 1.0%, proline 1.2%, KH 2 PO 4 0.15%, magnesium sulfate heptahydrate 0.05%, MES buffer salt 1.5%, pH 5.3.

[0019] 50L fermenter culture, 30L medium, sterilized at 121°C for 30 minutes. The seed volume is 1.5L, the culture temperature of the fermentation broth is 25°C, the initial ventilation volume is 0.9VVM, 200 rpm, and the tank pressure is 0.05Mpa. The maximum amount is 1.2VVM.

[0020] After 48 hours of fermentation, start to add vitamin b5, the added amount is 30mg / l. After 72 hours of fermentation (at this time, the ventilation rate and rotation speed have been adjusted to the upper limit), adjust the pH control range according to the change of dissolved oxygen until the end of fermentation: when the dissolved oxygen content is not lower than 45%, control the pH to 5.0-5.4, and the dissolved oxygen content in 96 hours 35%-45%, control pH 5.4-5....

Embodiment 2

[0021] Embodiment 2 (the comparative example that does not supplement vitamin b5)

[0022] Fermentation strain: Glarea lozoyensis

[0023] Fermentation medium (wt): lactose 3.0%, threonine 1.0%, yeast powder 1.0%, proline 1.2%, KH 2 PO 4 0.15%, magnesium sulfate heptahydrate 0.05%, MES buffer salt 1.5%, pH 5.3.

[0024] 50L fermenter culture, 30L medium, sterilized at 121°C for 30 minutes. The seed volume is 1.5L, the culture temperature of the fermentation broth is 25°C, the initial ventilation volume is 0.9VVM, 200 rpm, and the tank pressure is 0.05Mpa. The maximum amount is 1.2VVM.

[0025] After 72 hours of fermentation (at this time, the ventilation rate and rotation speed have been adjusted to the upper limit), adjust the pH control range according to the change of dissolved oxygen until the end of fermentation: when the dissolved oxygen content is not lower than 45%, control the pH to 5.0-5.4, and the dissolved oxygen content in 96 hours 35%-45%, control pH 5.4-5.8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com