Quantum dot composite material and preparation method thereof and quantum dot LED

A technology of composite materials and quantum dots, which is applied in the field of quantum dot composite materials and its preparation, and can solve problems such as the reduction of luminous efficiency of quantum dots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

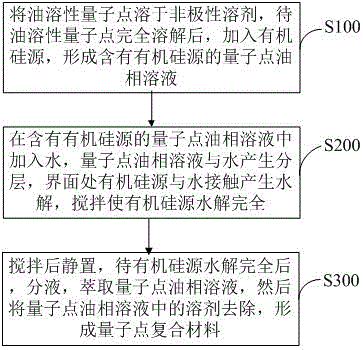

Method used

Image

Examples

Embodiment 1

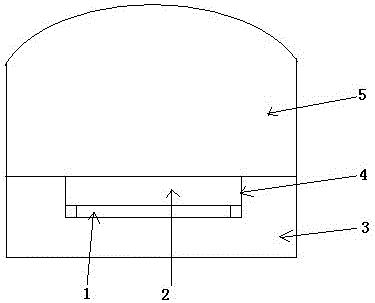

[0041] The preparation steps of yellow light quantum dot LED are as follows:

[0042] 1. Yellow light quantum dots Cd 1-x Zn x Se y S 1-y Preparation

[0043] 1) Preparation of cadmium-zinc precursor mixture: 0.6 mmol cadmium oxide (CdO), 6 mmol zinc acetate (Zn(Ac) 2 ), 24mmol octadecylphosphonic acid (ODPA), and 15mL trioctylamine (TOA) were placed in a 100mL three-necked flask, heated to 150℃ and degassed under Ar atmosphere for 30 min. Put this mixture in N 2 Heat to 310 ℃ in an atmosphere until a clear and transparent cadmium-zinc precursor mixture is formed.

[0044] 2) Preparation of selenium-sulfur precursor mixture: mix 0.6 mmol selenium powder (Se), 4.35 mmol sulfur powder (S) and 3 mL trioctylphosphine (TOP), and heat and stir at 140 ℃ for 30 min, until a colorless and transparent selenium-sulfur precursor mixture is formed.

[0045] 3) Oil-soluble quantum dots Cd 1-x Zn x Se y S 1-y Preparation: Heat the cadmium-zinc precursor mixture to 310°C, and then quickly inject the...

Embodiment 2

[0051] The preparation steps of the red light quantum dot LED are as follows:

[0052] 1. Preparation of red light quantum dots CdSe / CdS / ZnS

[0053] 1) Preparation of cadmium oleate precursor mixture: Take 1 mmol CdO, 8 mmol oleic acid and 16 mL trioctylamine in a 100 mL three-necked flask, heat to 250°C under Ar atmosphere and exhaust for 1 hour to form transparent oleic acid Cadmium precursor mixture.

[0054] 2) Preparation of Se-TOP precursor mixture: Dissolve 0.25 mmol Se powder in 0.25 mL TOP solution and heat it at 80°C for 10 min to form a colorless and transparent Se-TOP precursor mixture.

[0055] 3) Preparation of the mixture of deca mercaptan and trioctylamine: mix 0.75 mmol deca mercaptan and trioctylamine in a volume ratio of 1:9, and stir at room temperature for 10 min to form deca mercaptan and trioctylamine 的mixture. 4) Preparation of zinc oleate precursor mixture: take 4 mmolZn(Ac) 2 With 4mL oleic acid and 2mL trioctylamine in a 100mL three-necked flask, heated to...

Embodiment 3

[0063] The preparation steps of green light quantum dot LED are as follows:

[0064] 1. Preparation of green light quantum dots CdSe / ZnS

[0065] 1) Preparation of cadmium oleate-zinc precursor mixture: take 0.2mmol CdO, 4mmol zinc acetate, 8mmol oleic acid and 15mL 1-octadecene in a 100mL three-necked flask, heat to 170℃ and exhaust under Ar atmosphere 1h, a transparent cadmium oleate-zinc precursor mixture is formed.

[0066] 2) Preparation of Se-S-TOP precursor mixture: 0.1mmol Se powder and 3.5 mmol S powder were dissolved in 2 mL trioctylphosphine at 140℃ to form a colorless and transparent Se-S-TOP precursor Mixture.

[0067] 3) Preparation of green light quantum dots CdSe / ZnS: The cadmium oleate-zinc precursor mixture is slowly heated to 300°C, and the Se-S-TOP precursor mixture is quickly injected once, and the reaction is maintained for 10 minutes. Then the temperature was lowered to 100°C, ethyl acetate was added for washing, and centrifuged to obtain a precipitate. Then,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com