Antiseptic and anti-pollution polyvinyl acetate emulsion white glue

A technology of polyvinyl acetate and emulsion, which is applied in the direction of monocarboxylate copolymer adhesives, adhesive types, adhesive additives, etc., can solve the problems of poor antibacterial performance, poor adhesion, and reduction. Achieve good environmental protection and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

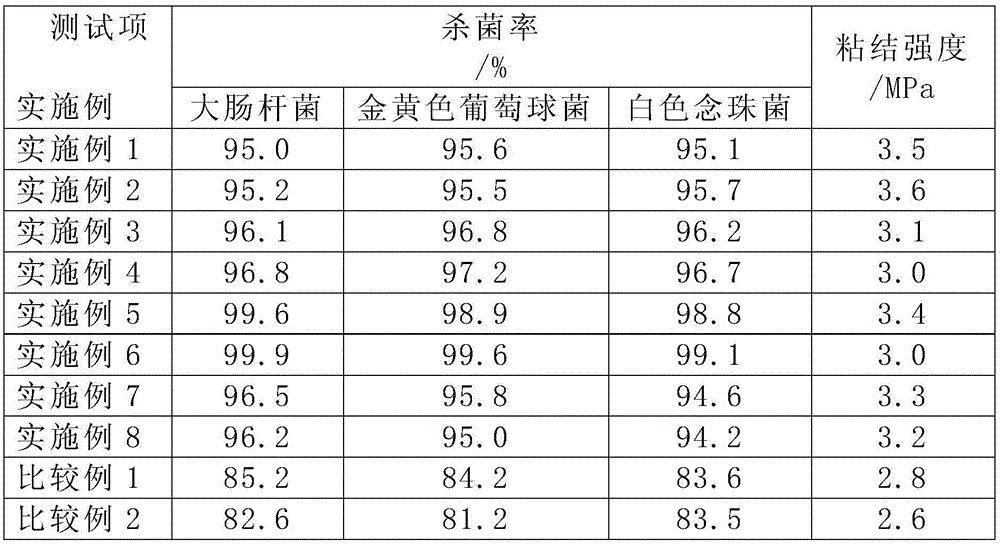

Examples

Embodiment 1

[0023] This anti-corrosion and anti-fouling polyvinyl acetate emulsion white glue is mainly made of the following raw materials in mass percentage:

[0024] VAc monomer: 50wt%; Alkylphenol polyoxyethylene ether: 3.0wt%; Potassium persulfate: 0.2wt%; Diethylene glycol dibenzoate: 3.0wt%; Dibutyl-4-isothiolin-3-one: 5.0wt%; film-forming aid dibutyl maleate: 1.0wt%; bispyridinethione: 0.02wt%; the balance is water.

[0025] The specific preparation method of this anti-corrosion and anti-fouling polyvinyl acetate emulsion white glue is as follows:

[0026] Weigh the raw materials according to the mass percentage ratio of the above raw materials, first add the emulsifier, VAc monomer and water into the reactor, and after the temperature is raised to 70°C, dissolve the initiator potassium persulfate or ammonium persulfate pre-dissolved in water The reaction is carried out dropwise. During the dropwise addition, the temperature of the reaction is controlled at about 68°C to 70°C. Af...

Embodiment 2

[0028] This anti-corrosion and anti-fouling polyvinyl acetate emulsion white glue is mainly made of the following raw materials in mass percentage:

[0029] VAc monomer: 30wt%; Glyceryl monostearate: 2.0wt%; Potassium persulfate: 0.1wt%; Triethyl citrate: 1.2wt%; Benzisothiazolinone: 3.0wt%; Dibutyl adipate: 3.0wt%; bispyridinethione: 0.04wt%; the balance is water.

[0030] The specific preparation method of the anti-corrosion and anti-fouling polyvinyl acetate emulsion white glue is consistent with that of Example 1, and will not be repeated here.

Embodiment 3

[0032] This anti-corrosion and anti-fouling polyvinyl acetate emulsion white glue is mainly made of the following raw materials in mass percentage:

[0033] VAc monomer: 40wt%; isomeric decanol ether phosphate: 1.2wt%; potassium persulfate: 0.2wt%; triethyl citrate: 2.0wt%; Ketone: 4.0wt%; Coalescing agent dibutyl adipate: 3.0wt%; Dipyridinethione: 0.03wt%; 2-hydroxypropyltrimethylammonium chloride chitosan: 1.0wt%; The amount is water.

[0034]The specific preparation method of the anti-corrosion and anti-fouling polyvinyl acetate emulsion white glue is consistent with that of Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com