Low-roughness coating for automobile surface and preparation method of low-roughness coating

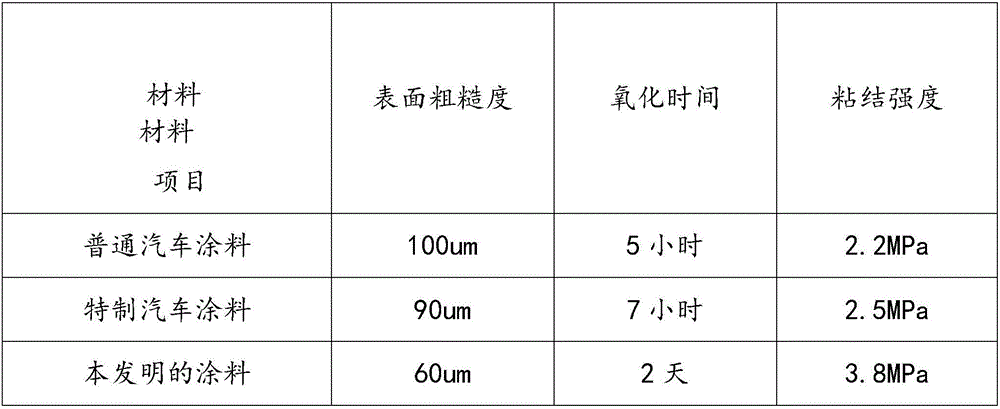

A technology for automobile surface and roughness, applied in wax coating, polyester coating, coating, etc., can solve the problems of poor anti-oxidation effect, low bonding strength, high surface roughness, etc. The effect of high junction strength and low surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A paint with low surface roughness for automobiles, made of the following materials in parts by weight, including 26 parts of distilled water, 8 parts of alkyd resin, 7 parts of polyvinyl alcohol, 16 parts of polyacrylic acid emulsion, chlorosulfonated polyethylene 9 parts of resin emulsion, 16 parts of vinylidene chloride, 13 parts of water-based wax, 20 parts of clay, 6 parts of titanium dioxide, 11 parts of expanded vermiculite, 6 parts of ethyl acetoacetate, 10 parts of polysorbate, 4 parts of sodium salicylate , 16 parts of p-aminobenzoic acid, 8 parts of nicotinamide and 20 parts of aluminum powder.

[0019] A method for preparing a coating with low surface roughness for automobiles, comprising the following steps:

[0020] 1) Put 26 parts of distilled water, 8 parts of alkyd resin, 7 parts of polyvinyl alcohol, 16 parts of polyacrylic acid emulsion, 9 parts of chlorosulfonated polyethylene resin emulsion, 16 parts of vinylidene chloride, and 13 parts of water-bas...

Embodiment 2

[0026] A coating with low surface roughness for automobiles, made of the following materials in parts by weight, including 28 parts of distilled water, 11 parts of alkyd resin, 9 parts of polyvinyl alcohol, 22 parts of polyacrylic acid emulsion, chlorosulfonated polyethylene 12 parts of resin emulsion, 18 parts of vinylidene chloride, 14 parts of water-based wax, 22 parts of clay, 7 parts of titanium dioxide, 13 parts of expanded vermiculite, 7.5 parts of ethyl acetoacetate, 11 parts of polysorbate, 6 parts of sodium salicylate , 18 parts of p-aminobenzoic acid, 10.5 parts of nicotinamide and 21 parts of aluminum powder.

[0027] A method for preparing a coating with low surface roughness for automobiles, comprising the following steps:

[0028] 1) Put 28 parts of distilled water, 11 parts of alkyd resin, 9 parts of polyvinyl alcohol, 22 parts of polyacrylic acid emulsion, 12 parts of chlorosulfonated polyethylene resin emulsion, 18 parts of vinylidene chloride, and 14 parts o...

Embodiment 3

[0034] A paint with low surface roughness for automobiles, made of the following materials in parts by weight, including 32 parts of distilled water, 14 parts of alkyd resin, 11 parts of polyvinyl alcohol, 28 parts of polyacrylic acid emulsion, chlorosulfonated polyethylene 15 parts of resin emulsion, 20 parts of vinylidene chloride, 15 parts of water-based wax, 24 parts of clay, 8 parts of titanium dioxide, 15 parts of expanded vermiculite, 9 parts of ethyl acetoacetate, 12 parts of polysorbate, 8 parts of sodium salicylate , 20 parts of p-aminobenzoic acid, 13 parts of nicotinamide and 22 parts of aluminum powder.

[0035] A method for preparing a coating with low surface roughness for automobiles, comprising the following steps:

[0036]1) Put 32 parts of distilled water, 14 parts of alkyd resin, 11 parts of polyvinyl alcohol, 28 parts of polyacrylic acid emulsion, 15 parts of chlorosulfonated polyethylene resin emulsion, 20 parts of vinylidene chloride, and 15 parts of wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com