A kind of pumice cement phenolic resin composite foam material and preparation method thereof

A phenolic resin and composite foam technology, applied in the field of thermal insulation foam materials, can solve the problems of poor thermal insulation performance of inorganic thermal insulation materials, low strength and poor water resistance of organic phenolic foam materials, etc. The effect of improving the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

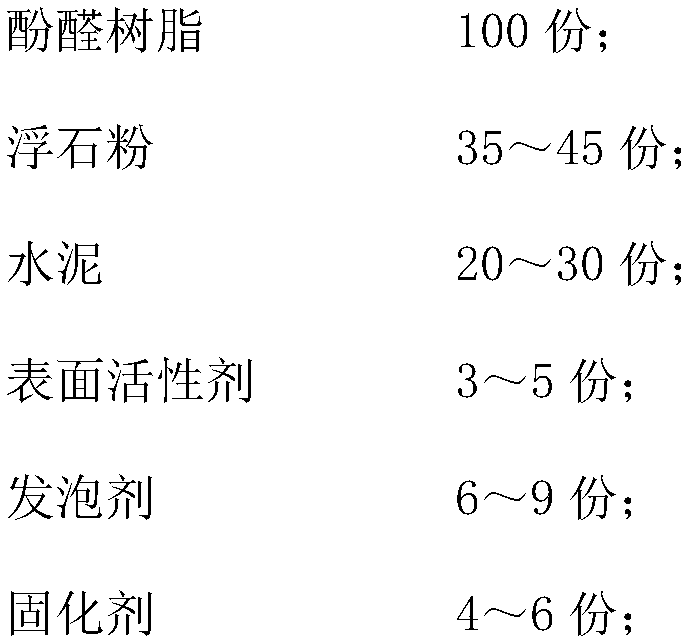

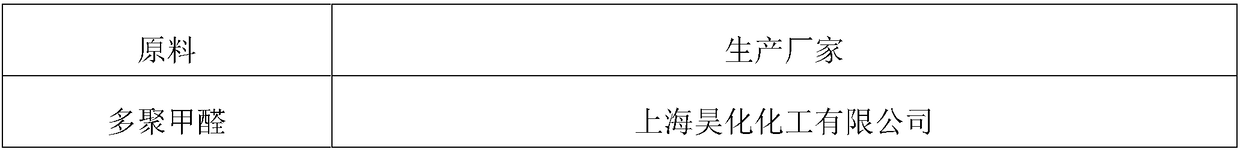

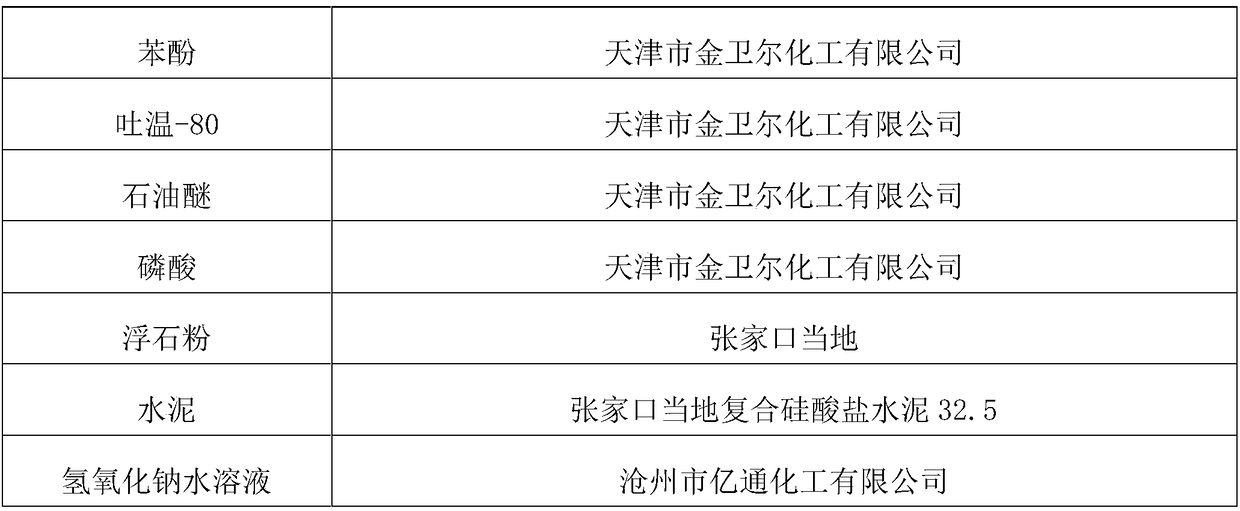

[0043] The pumice cement phenolic resin composite foam material is composed of phenolic resin, pumice powder, cement, Tween-80, petroleum ether, and phosphoric acid. The weight ratio of each component is as follows: 100 parts of phenolic resin; 40 parts of pumice powder; 22 parts of cement ; 4 parts of surfactant; 7 parts of foaming agent; 5 parts of curing agent. Among them, the phenolic resin is prepared from phenol, paraformaldehyde and alkaline catalyst sodium hydroxide aqueous solution, and its mass ratio is phenol:paraformaldehyde:20% sodium hydroxide aqueous solution=100:60:1.5.

Embodiment 2

[0045]The pumice cement phenolic resin composite foam material is composed of phenolic resin, pumice powder, cement, Tween-80, petroleum ether, and phosphoric acid. The weight ratio of each component is as follows: 100 parts of phenolic resin; 35 parts of pumice powder; 25 parts of cement ; 3 parts of surfactant; 6 parts of foaming agent; 4 parts of curing agent. Among them, the phenolic resin is prepared from phenol, paraformaldehyde and alkaline catalyst sodium hydroxide aqueous solution, and its mass ratio is phenol:paraformaldehyde:20% sodium hydroxide aqueous solution=90:50:2.5.

Embodiment 3

[0047] The pumice cement phenolic resin composite foam material is composed of phenolic resin, pumice powder, cement, Tween-80, petroleum ether, and phosphoric acid. The weight ratio of each component is as follows: 100 parts of phenolic resin; 45 parts of pumice powder; 20 parts of cement ; 5 parts of surfactant; 7.5 parts of foaming agent; 6 parts of curing agent. Among them, the phenolic resin is prepared from phenol, paraformaldehyde and alkaline catalyst sodium hydroxide aqueous solution, and its mass ratio is phenol:paraformaldehyde:20% sodium hydroxide aqueous solution=95:55:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com