Aluminate light conversion agent and preparation method thereof as well as light conversion film containing aluminate light conversion agent

A technology of aluminate and light-transforming agent, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of reduced luminous intensity, easy hydrolysis and photolysis, and fast intensity attenuation, and achieves improved luminous intensity, simple preparation method, Light transmittance has little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the above aluminate light conversion agent includes the following steps: grinding and mixing metal oxides, nano metal oxides, alkaline earth salts, activators and fluxes uniformly, then adding them into a crucible, and placing them in a high-temperature furnace to proceed with the procedure Heating and cooling: 1) Raise temperature to 250~350℃ at a heating rate of 5~10℃ / min, and react at a constant temperature for 20~40 minutes; 2) Raise temperature to 1500~1600℃ at a heating rate of 5~10℃ / min, constant temperature React for 2 to 4 hours; 3) Cool down to 500 to 600°C at a temperature drop rate of 3 to 8°C / min, then naturally cool to room temperature, and take out the furnace to obtain the aluminate light conversion agent.

[0035] Preferably, the mass ratio of the metal oxide to the nano metal oxide is 1: (0.25-4).

[0036] Preferably, the ratio of the amount of alkaline earth salts to the total amount of metal oxides and nano metal oxides is 1: (0....

Embodiment 1

[0061] Example 1: Aluminate light conversion agent CaAl 12 O 19 :Mn 4+

[0062] 1) Production materials:

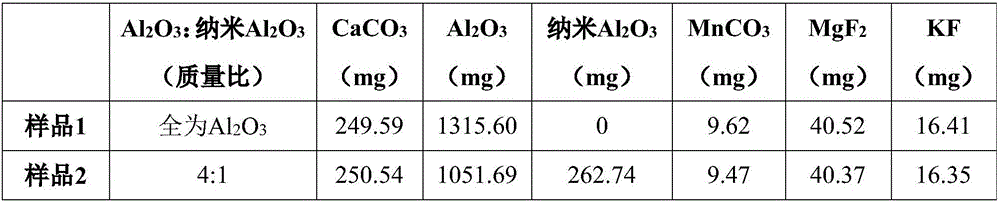

[0063] The production materials of samples 1-7 are shown in Table 1:

[0064] Table 1 Production raw material composition table of samples 1-7

[0065]

[0066]

[0067] 2) Production process:

[0068] Will Al 2 O 3 Nano Al 2 O 3 , CaCO 3 , MnCO 3 , MgF 2 Weigh KF and KF according to the ratio in Table 1, grind and mix thoroughly, add them to the crucible, place in a high-temperature furnace, and perform programmed heating and cooling: 1) Raise temperature to 300℃ at a heating rate of 5℃ / min, and react at a constant temperature for 30 minutes; 2) Raise the temperature to 1550°C at a temperature rise rate of 10°C / min, and react at a constant temperature for 3 hours; 3) Cool down to 550°C at a temperature drop rate of 8°C / min, then cool to room temperature naturally, and leave the furnace to obtain the aluminate conversion agent CaAl 12 O 19 :Mn 4+ .

[0069] 3) Luminescence propert...

Embodiment 2

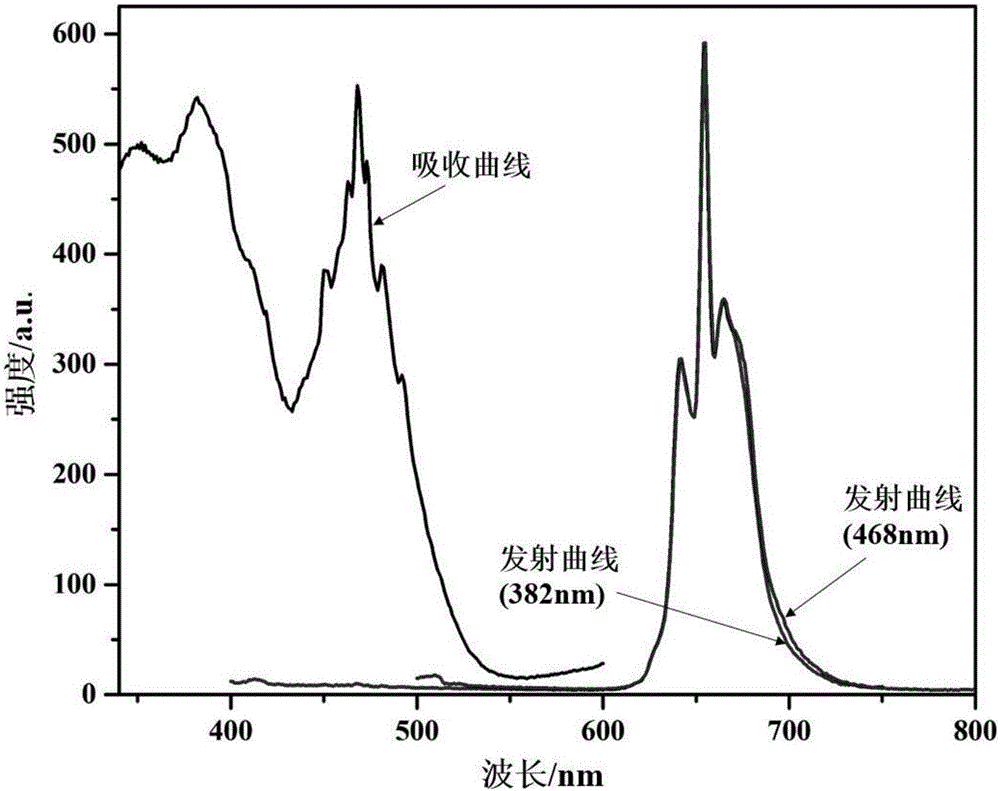

[0074] The excitation spectrum and emission spectrum of the aluminate light conversion agent sample 4 prepared in this embodiment are as follows: figure 1 As shown, the SEM image is as figure 2 Shown. by figure 1 Known: Aluminate conversion agent CaAl 12 O 19 :Mn 4+ The absorption peaks of sample 4 are located at 382nm and 468nm, and the aluminate light conversion agent CaAl is excited by light with wavelengths of 382nm and 468nm. 12 O 19 :Mn 4+ For sample 4, the strongest emission peaks are all located at 655nm. Example 2: Aluminate light conversion agent CaAl 12 O 19 :Mn 4+

[0075] 1) Production materials

[0076] The production raw materials of samples 1-7 are shown in Table 3:

[0077] Table 3 Production raw material composition table of samples 1-7

[0078]

[0079] 2) Production process

[0080] Will Al 2 O 3 Nano Al 2 O 3 , CaCO 3 , Mn 3 O 4 , MgF 2 Weigh KF and KF according to the ratio in Table 3, grind and mix well, add them to the crucible, place in a high-temperature fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com