Polyhydroxyalkylphenyl polysilsesquioxane and preparation method and application thereof

A technology of polysilsesquioxane and polyhydroxyalkyl benzene is applied in the field of polysilsesquioxane POSS and its modified materials, which can solve the problem that the flame retardancy and mechanical properties of polyurethane materials cannot be satisfied at the same time. The flame retardant effect is lasting and stable, the heat resistance and mechanical properties are improved, and the smoke suppression effect is obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 Preparation of Polysilsesquioxane Modified Polyurethane Rigid Foaming Material

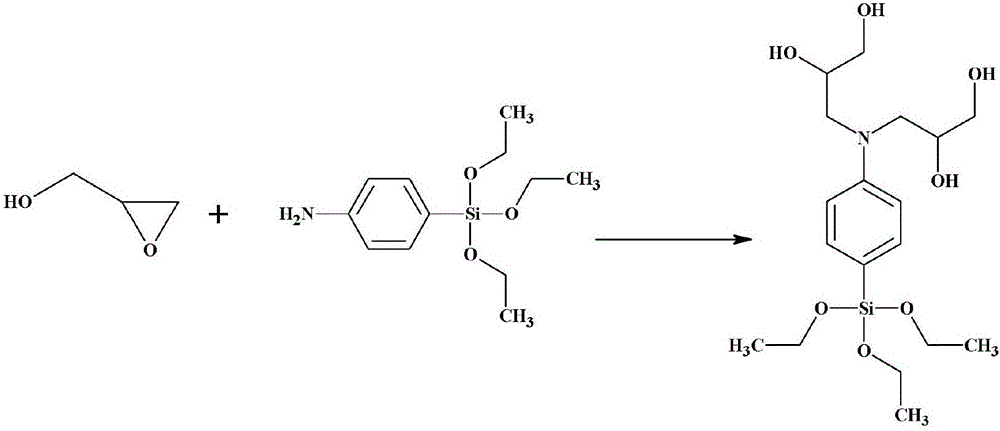

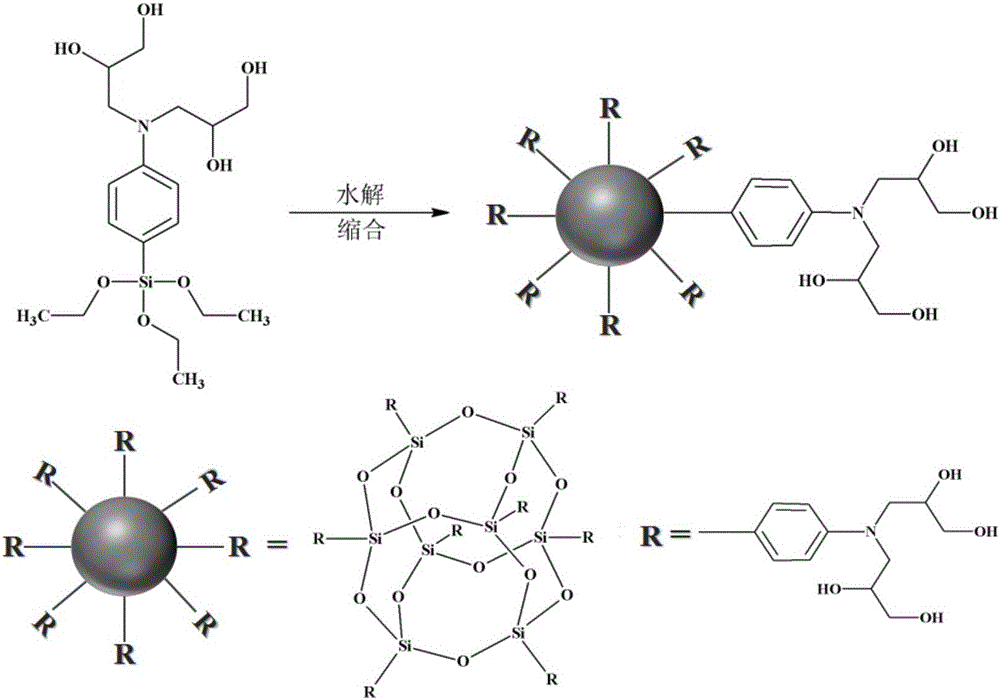

[0043] Synthesis of polyhydroxyalkylphenyl polysilsesquioxanes:

[0044] (1) Weigh glycidyl alcohol and 4-aminophenyltriethoxysilane respectively, under nitrogen protection, in an ice-water bath, add 4-aminophenyltriethoxysilane dropwise to glycidyl alcohol, and the mixture React at 20°C for 5 hours, the molar ratio of glycidol to 4-aminophenyltriethoxysilane is 0.5:1;

[0045] (2) Dissolve the product in (1) in a methanol solution, add dropwise an aqueous hydrogen fluoride solution with a mass concentration of 1.5% under stirring conditions, stir at 20°C for 4 hours, and remove water, methanol, and ethanol by distillation under reduced pressure after the reaction is completed. Vacuum drying at 30°C and -0.080MPa for 1 h to obtain polyhydroxyalkylphenyl polysilsesquioxane POSS nanoparticles, wherein the mass ratio of 4-aminophenyltriethoxysilane to methanol is 1:3, 4- The mass r...

Embodiment 2

[0060] Example 2 Preparation of Polysilsesquioxane Modified Polyurethane Rigid Foaming Material

[0061] Synthesis of polyhydroxyalkylphenyl polysilsesquioxanes:

[0062] (1) Weigh glycidyl alcohol and 4-anilinotriethoxysilane respectively, under the protection of nitrogen, in an ice-water bath, add 4-anilinotriethoxysilane dropwise to glycidol, and the mixture will be at 25 Reaction at ℃ for 10h, the molar ratio of glycidol to 4-anilinotriethoxysilane is 2:1;

[0063] (2) Dissolve the product in (1) in a methanol solution, add dropwise a hydrogen fluoride solution with a mass concentration of 3.5% under stirring conditions, stir at 25° C. for 10 h, and remove water, methanol, and ethanol by distillation under reduced pressure after the reaction is completed. Vacuum drying at 40°C and -0.080MPa for 5 hours to obtain polyhydroxyalkylphenylpolysilsesquioxane POSS nanoparticles, wherein the mass ratio of 4-anilinotriethoxysilane to methanol is 1:10, 4-aniline The mass ratio of ...

Embodiment 3

[0080] Example 3 Preparation of Polysilsesquioxane Modified Polyurethane Rigid Foaming Material

[0081] Synthesis of polyhydroxyalkylphenyl polysilsesquioxanes:

[0082] (1) Weigh glycidyl alcohol and 4-anilinotriethoxysilane respectively, under the protection of nitrogen, in an ice-water bath, add 4-anilinotriethoxysilane dropwise to glycidyl alcohol, and the mixture is at 23 Reaction at ℃ for 8h, the molar ratio of glycidol and 4-anilinotriethoxysilane is 1:1;

[0083] (2) Dissolve the product in (1) in a methanol solution, add dropwise a hydrogen fluoride aqueous solution with a mass concentration of 2.0% under stirring conditions, stir for 5 hours at 24°C, and remove water, methanol, and ethanol by distillation under reduced pressure after the reaction is completed. Vacuum drying at 38°C and -0.080MPa for 3 hours to obtain polyhydroxyalkylphenyl polysilsesquioxane POSS nanoparticles, in which the mass ratio of 4-anilinotriethoxysilane to methanol is 1:5,4-aniline The ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com