A kind of polyurethane raw material composition for expressway repair and using method thereof

A raw material composition and highway technology, applied in the field of polyurethane raw material composition for highway repair, can solve problems such as high viscosity, incompetent mechanical strength, high toxicity, etc., achieve wide sources, convenient large-scale production, and use methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

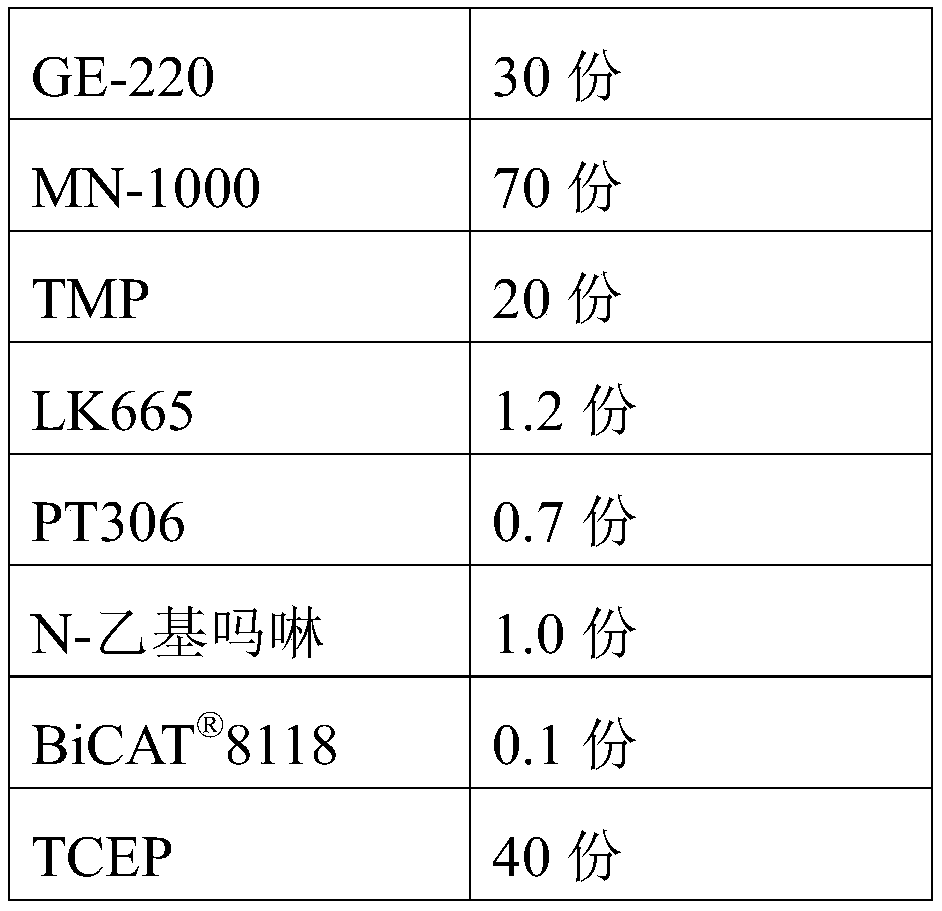

[0029] Table 1 A component raw material composition table in Example 1

[0030]

[0031] Pour the raw materials of component A into the container according to the ratio specified in Table 1, and use an electric mixer to mix evenly to obtain component A; use PM200 for component B; then mix component A and component B according to the weight ratio of 1:1.2 Pour the ratio into a container, then stir with an electric mixer for 8 seconds, pour the evenly mixed liquid into an open container at room temperature, and place it for 24 hours before performing a performance test to obtain a polyurethane material for highway repair.

Embodiment 2

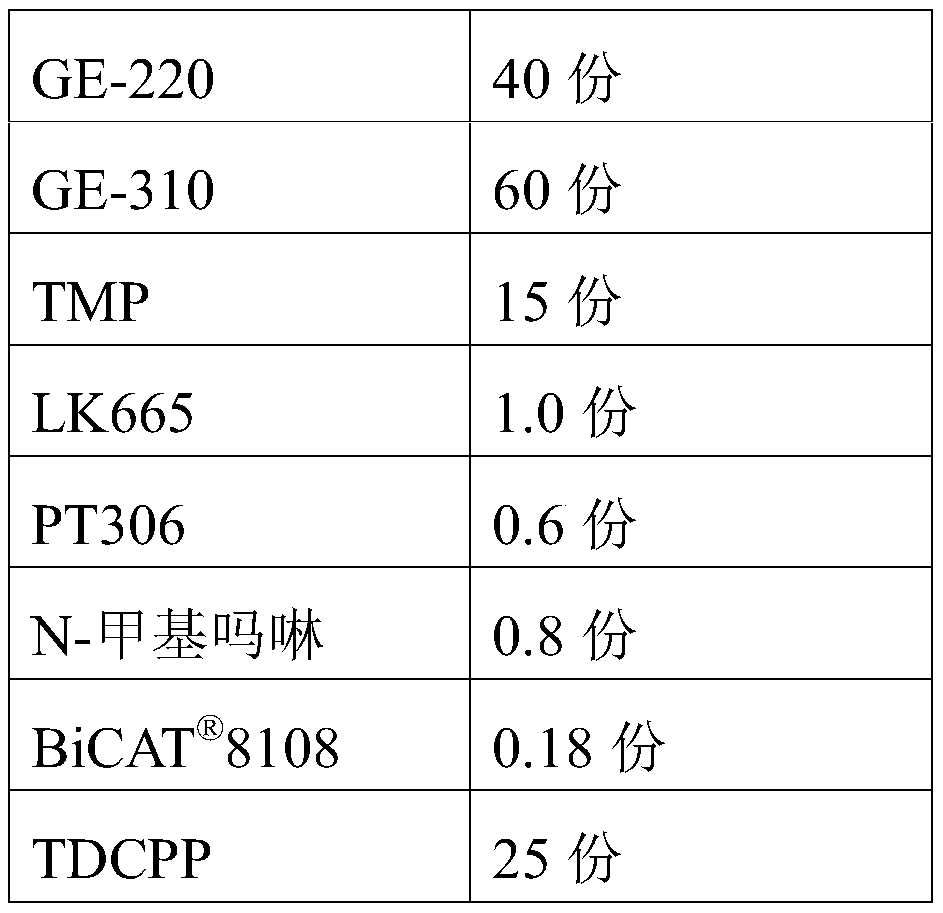

[0033]Table 2 A component raw material composition table in Example 2

[0034]

[0035] Pour the raw materials of component A into the container according to the ratio specified in Table 2, and use an electric mixer to mix evenly to obtain component A; use PM400 for component B; then mix component A and component B according to the weight ratio of 1:1.15 Pour the ratio into a container, then stir with an electric mixer for 8 seconds, pour the evenly mixed liquid into an open container at room temperature, and place it for 24 hours before performing a performance test to obtain a polyurethane material for highway repair.

Embodiment 3

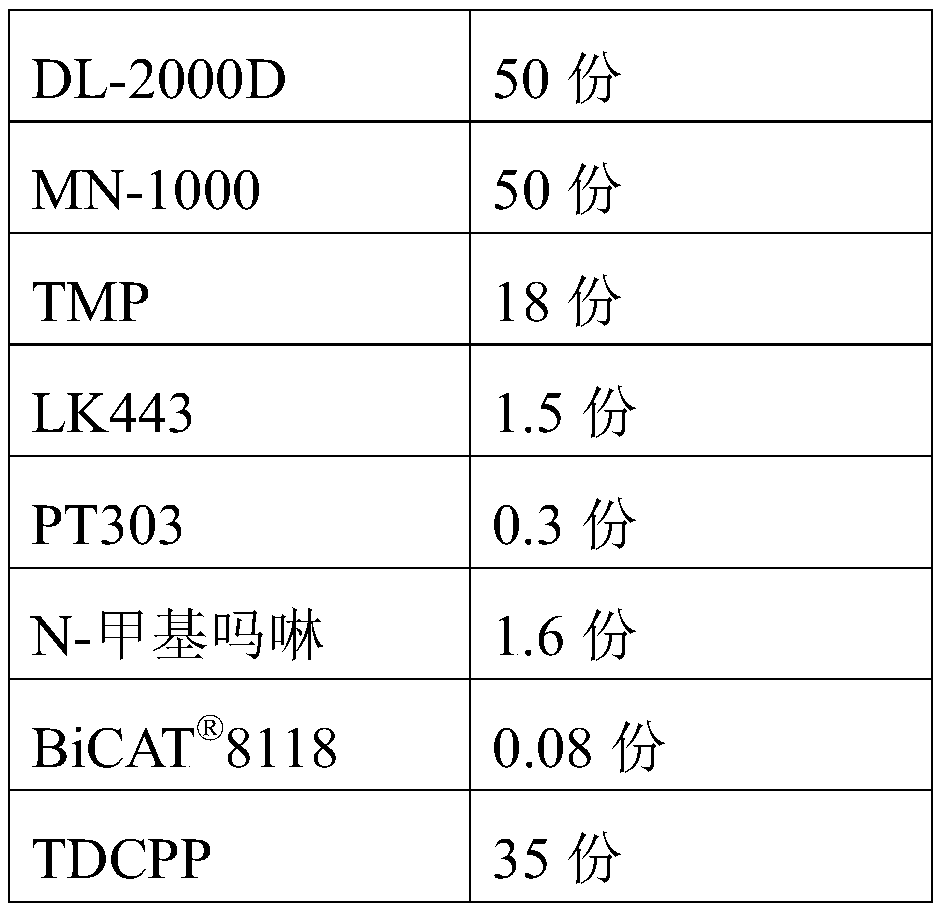

[0037] Table 3 A component raw material composition table in embodiment 3

[0038]

[0039] Pour the raw materials of component A into the container according to the ratio specified in Table 3, and use an electric mixer to mix evenly to obtain component A; use M20S for component B; then mix components A and B according to the weight ratio of 1:1.13 Pour the ratio into a container, then stir with an electric mixer for 8 seconds, pour the evenly mixed liquid into an open container at room temperature, and place it for 24 hours before performing a performance test to obtain a polyurethane material for highway repair.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com