Polyurethane raw material composite for repairing expressway and using method thereof

A raw material composition, a technology for expressways, applied in the field of polyurethane raw material composition for expressway repair, can solve the problems of high viscosity, high toxicity, incompetent mechanical strength, etc. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

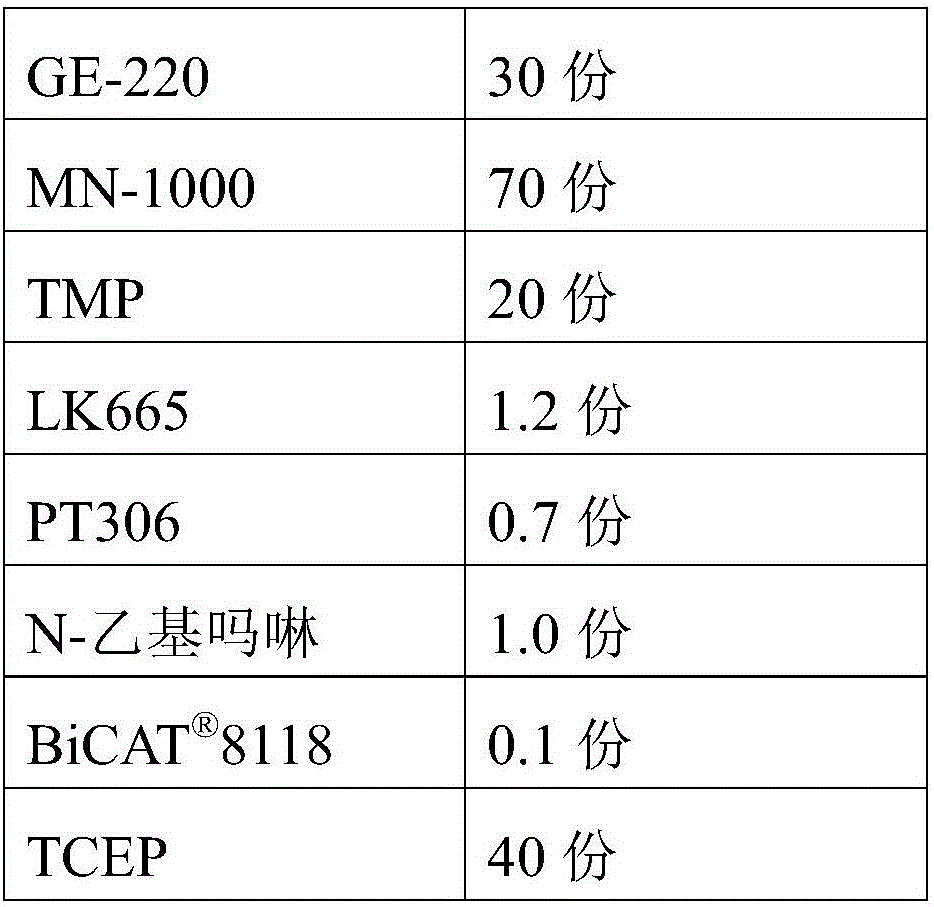

[0029] Table 1 A component raw material composition table in Example 1

[0030]

[0031] Pour the raw materials of component A into the container according to the ratio specified in Table 1, and use an electric mixer to mix evenly to obtain component A; use PM200 for component B; then mix component A and component B according to the weight ratio of 1:1.2 Pour the ratio into a container, then stir with an electric mixer for 8 seconds, pour the evenly mixed liquid into an open container at room temperature, and place it for 24 hours before performing a performance test to obtain a polyurethane material for highway repair.

Embodiment 2

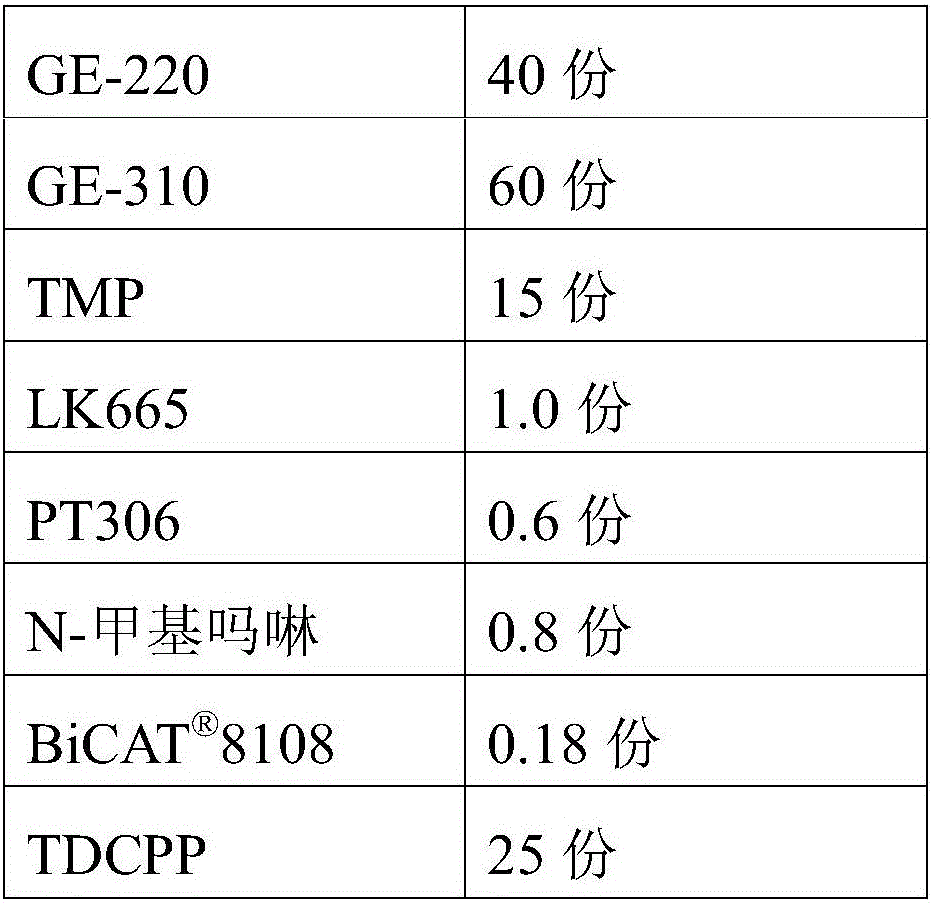

[0033]Table 2 A component raw material composition table in Example 2

[0034]

[0035] Pour the raw materials of component A into the container according to the ratio specified in Table 2, and use an electric mixer to mix evenly to obtain component A; use PM400 for component B; then mix component A and component B according to the weight ratio of 1:1.15 Pour the ratio into a container, then stir with an electric mixer for 8 seconds, pour the evenly mixed liquid into an open container at room temperature, and place it for 24 hours before performing a performance test to obtain a polyurethane material for highway repair.

Embodiment 3

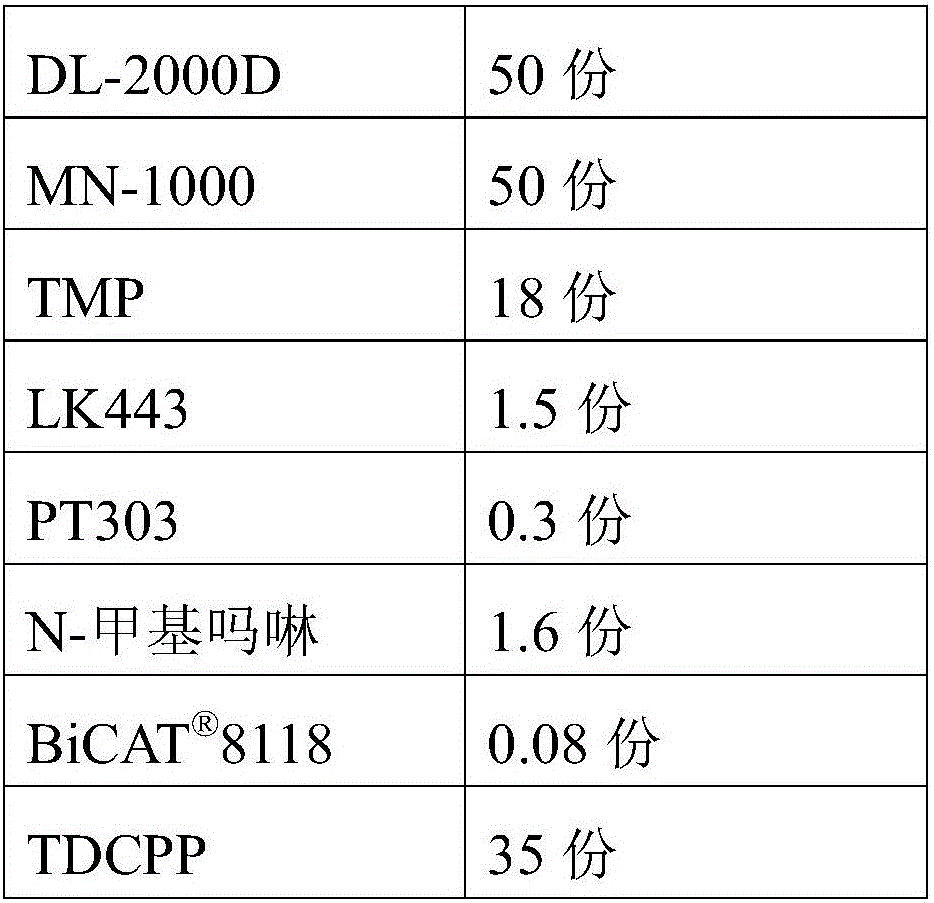

[0037] Table 3 A component raw material composition table in embodiment 3

[0038]

[0039] Pour the raw materials of component A into the container according to the ratio specified in Table 3, and use an electric mixer to mix evenly to obtain component A; use M20S for component B; then mix components A and B according to the weight ratio of 1:1.13 Pour the ratio into a container, then stir with an electric mixer for 8 seconds, pour the evenly mixed liquid into an open container at room temperature, and place it for 24 hours before performing a performance test to obtain a polyurethane material for highway repair.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com