Bio-organic fertilizer and preparation method thereof

A bio-organic fertilizer and bio-bacteria technology, which is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, and organic fertilizers, can solve problems such as environmental pollution of organic matter, and achieve the effects of low cost, uniform fermentation, and no soil compaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

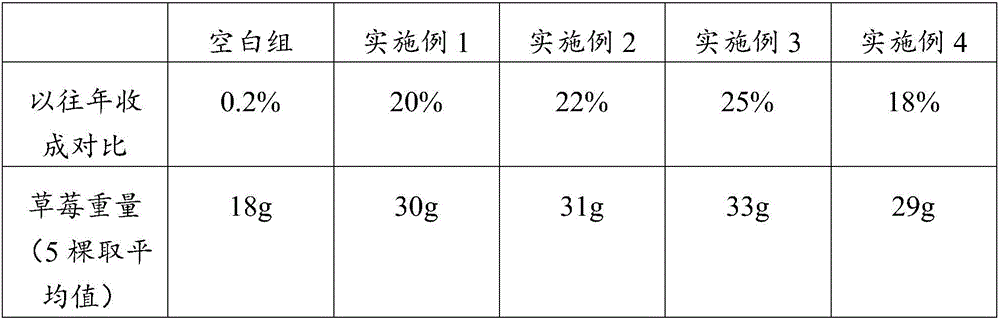

Examples

Embodiment 1

[0033] A bio-organic fertilizer, comprising the following raw materials in parts by weight: 80 parts of chicken manure, 50 parts of rice bran, 50 parts of cassava dregs, 30 parts of sugar factory filter mud, 5 parts of plant ash, 10 parts of medicinal dregs, 1 part of potassium fulvic acid, 5 parts of Bacillus megaterium, 5 parts of Angel yeast, 5 parts of compound additives;

[0034] The preparation method of described biological organic fertilizer comprises the following steps:

[0035] (1) Weigh chicken manure, rice bran, cassava dregs, sugar factory filter mud, plant ash, medicinal dregs and angel yeast respectively according to the ratio, mix them evenly, pile them up in the first fermentation field to form compost, and use a mass percentage of 2% The molasses solution prepared compost has a moisture content of 30% and a pH of 7.5;

[0036] (2) Pass the air duct of the aeration equipment to the bottom of the compost, and cover the compost with a polyethylene heat-insulat...

Embodiment 2

[0043] A biological organic fertilizer, comprising the following raw materials in parts by weight: 100 parts of pig manure, 30 parts of rice bran, 80 parts of cassava dregs, 10 parts of sugar factory filter mud, 10 parts of plant ash, 5 parts of medicine dregs, 5 parts of potassium fulvic acid, 1 part of soybean rhizobia, 10 parts of angel yeast, 1 part of compound additive;

[0044] The preparation method of described biological organic fertilizer comprises the following steps:

[0045] (1) Weigh pig manure, rice bran, cassava dregs, sugar factory filter mud, plant ash, medicinal dregs and angel yeast respectively according to the proportion, mix them evenly, pile them up in the first fermentation field to form compost, and use the mass percentage as 1% The acidic molasses solution prepared compost has a moisture content of 35% and a pH of 5.5;

[0046] (2) Pass the air duct of the aeration equipment to the bottom of the compost, and cover the compost with polyethylene heat-in...

Embodiment 3

[0053] A bio-organic fertilizer, comprising the following raw materials in parts by weight: 90 parts of cow dung, 40 parts of rice bran, 70 parts of cassava dregs, 20 parts of sugar factory filter mud, 8 parts of plant ash, 6 parts of medicinal dregs, 3 parts of potassium fulvic acid, 1 part of soybean rhizobia, 2 parts of EM flora, 8 parts of angel yeast, 4 parts of compound additives;

[0054] The preparation method of described biological organic fertilizer comprises the following steps:

[0055] (1) Weigh cow dung, rice bran, cassava dregs, sugar factory filter mud, plant ash, medicinal dregs and angel yeast respectively according to the proportioning ratio, mix them evenly, pile them up in the first fermentation field to form compost, and use a mass percentage of 1% The acidic molasses solution prepared compost has a moisture content of 35% and a pH of 6.0;

[0056] (2) Pass the air duct of the aeration equipment to the bottom of the compost, and cover the compost with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com