A kind of graphene-ceramic composite powder and preparation method thereof

A ceramic composite, graphene technology, applied in the direction of graphene, single-layer graphene, chemical instruments and methods, etc., can solve the problems of increasing production cost, long production cycle, human injury, etc., to reduce production cost and achieve better dispersion effect. Best, avoid the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of graphene-ceramic composite powder, comprising the following steps and process conditions thereof:

[0037] (1) Material preparation: according to the percentage of the total mass of GO and zirconia granulated powder, the mass ratio is: GO (made by Hummers method) 0.1wt.%, zirconia granulated powder 99.9wt.%;

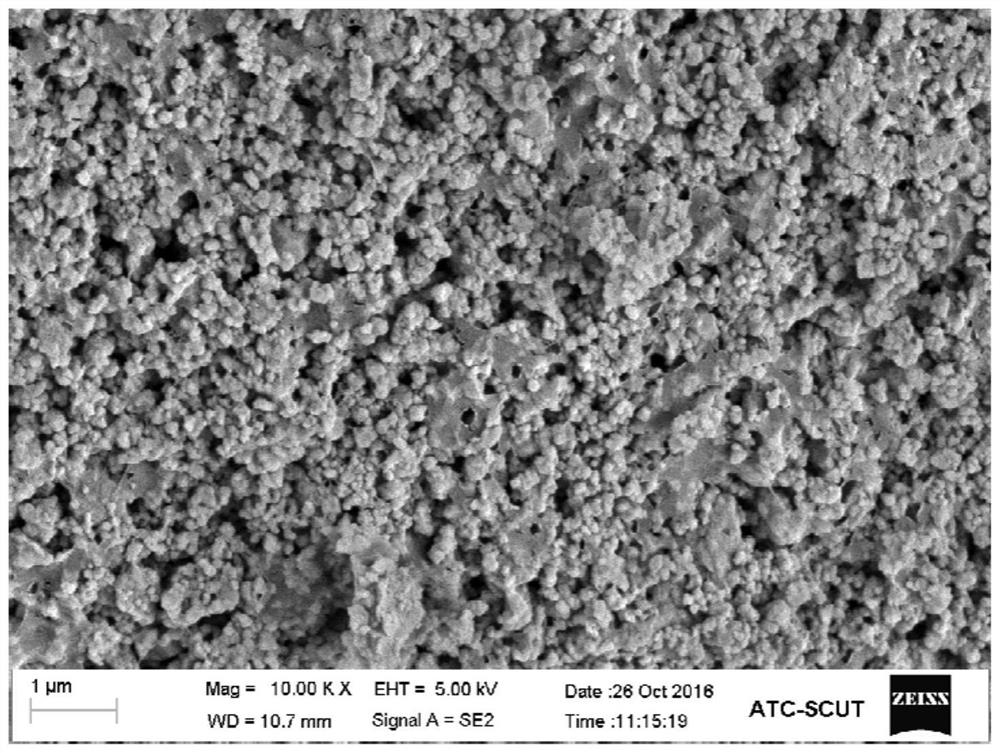

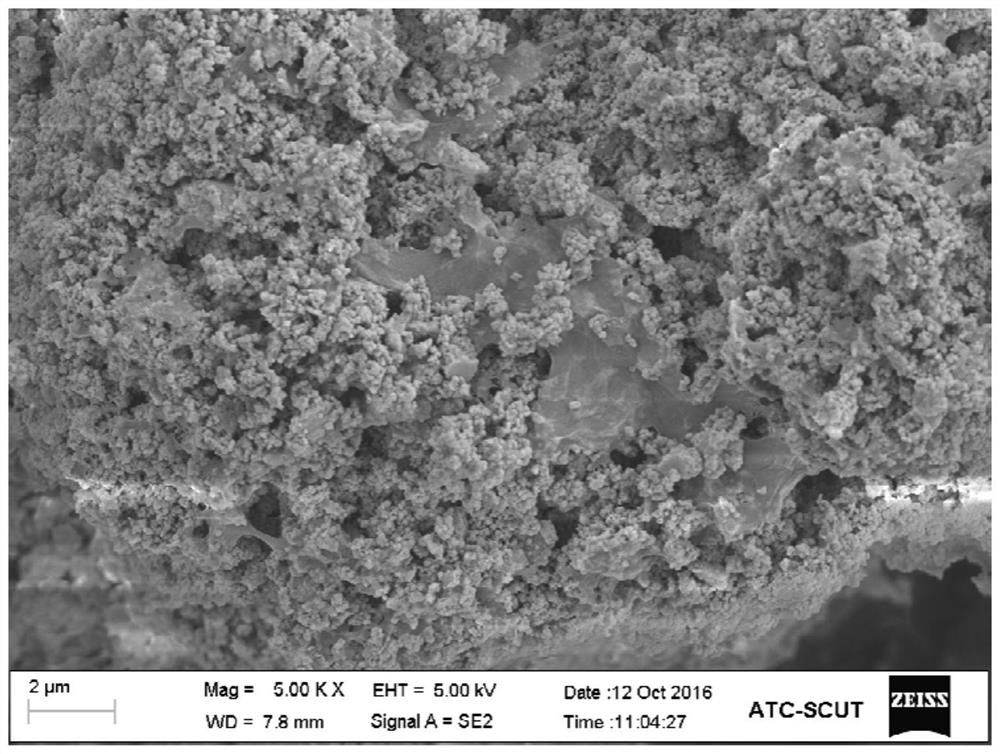

[0038] (2) Dispersion of graphene oxide: Add deionized water to the weighed graphene oxide to wet it for 20 minutes, then dilute with deionized water, stir, and sonicate for 30 minutes to obtain a concentration of 0.25 mg / mL Graphene oxide suspension;

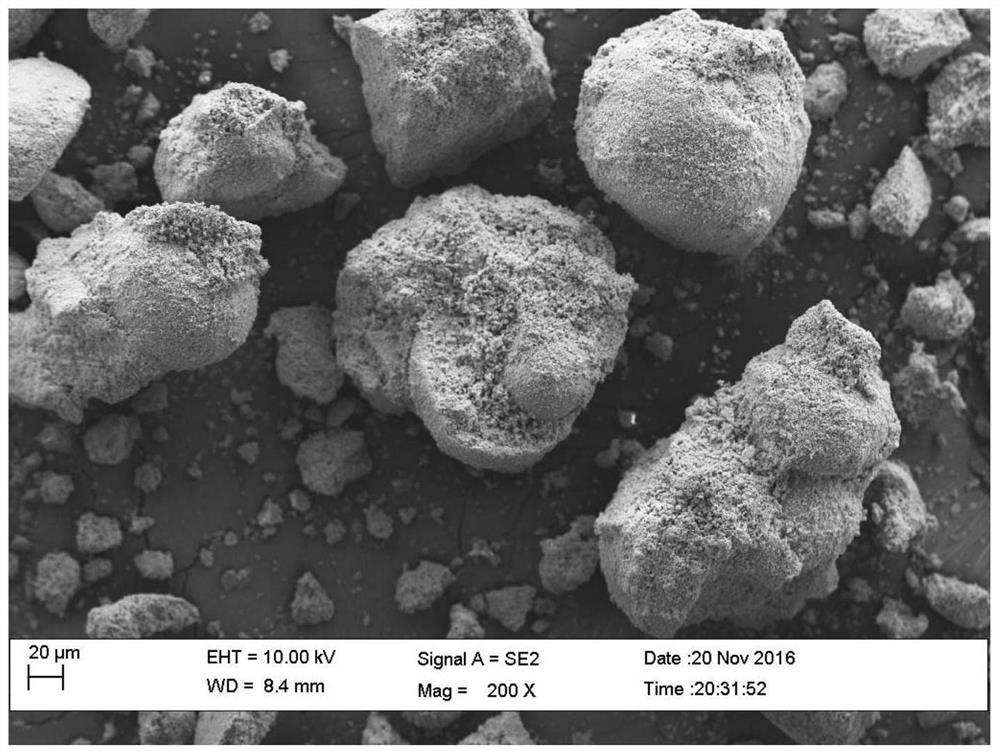

[0039] (3) Powder mixing: quickly add zirconia granulated powder to the above graphene oxide suspension, and stir for 10 minutes to obtain a mixture of graphene oxide and zirconia granulated powder;

[0040] (4) Powder drying: Suction filter the mixture of graphene oxide and zirconia granulated powder to obtain a mixed slurry, which is then vacuum-dried at 35°C with a drying pressure of 0 a...

Embodiment 2

[0044] A preparation method of graphene-ceramic composite powder, comprising the following steps and process conditions thereof:

[0045] (1) Raw material preparation: according to the mass percentage of the total mass of GO and zirconia granulated powder, the mass ratio is: GO (made by Hummers method) 0.5wt.%, zirconia granulated powder 99.5t.%;

[0046] (2) Dispersion of graphene oxide: Add deionized water to the weighed graphene oxide to wet it for 10 minutes, then dilute with deionized water, stir, and sonicate for 10 minutes to obtain a concentration of 0.35 mg / mL Graphene oxide suspension;

[0047] (3) Powder mixing: quickly add zirconia granulated powder to the above graphene oxide suspension, and stir for 5 minutes to obtain a mixture of graphene oxide and zirconia granulated powder;

[0048] (4) Powder drying: Suction filter the mixture of graphene oxide and zirconia granulated powder to obtain a mixed slurry, which is then dried in vacuum at 20°C with a drying pressur...

Embodiment 3

[0053] A preparation method of graphene-ceramic composite powder, comprising the following steps and process conditions thereof:

[0054] (1) Material preparation: according to the mass percentage of the total mass of GO and zirconia granulated powder, the mass ratio is: GO (made by Hummers method) 0.01wt.%, zirconia granulated powder 99.99wt.%;

[0055] (2) Dispersion of graphene oxide: Add deionized water to the weighed graphene oxide for wetting for 15 minutes, then dilute with deionized water, stir, and sonicate for 60 minutes to obtain a concentration of 0.05 mg / mL Graphene oxide suspension;

[0056] (3) Powder mixing: quickly add zirconia granulated powder to the above graphene oxide suspension, and stir for 15 minutes to obtain a mixture of graphene oxide and zirconia granulated powder;

[0057] (4) Powder drying: Suction filter the mixture of graphene oxide and zirconia granulated powder above to obtain mixed slurry, vacuum dry at 40°C, dry at a pressure of 1 atm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com