Steel slag activating agent and preparation method and application thereof

An activator and steel slag technology, applied in cement production and other directions, can solve the problems of restricting the utilization of steel slag as building materials, high content of free calcium oxide, poor volume stability, etc., to increase energy consumption and environmental burden, simple production process control, and finished products. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

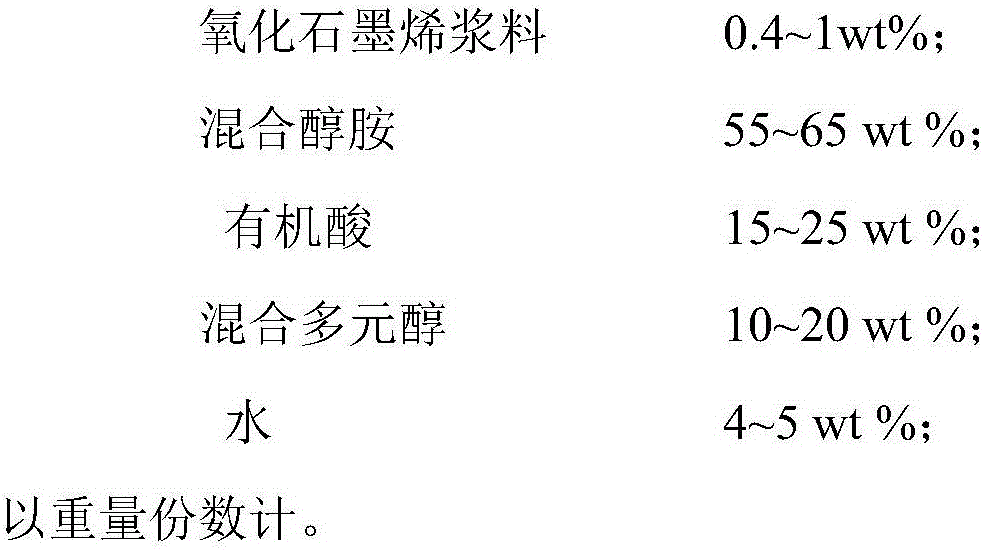

[0029] Embodiment 1: A steel slag activator, including the following components:

[0030]

[0031] The preparation method of the above-mentioned steel slag activator includes the following steps:

[0032] (1) Put the mixed alcohol amine, organic acid and mixed polyol into the reaction kettle in proportion, control the temperature at 35-40℃, and react for 2h under stirring conditions;

[0033] (2) Add graphene oxide slurry to the system in step (1), while raising the temperature to 120°C, adjusting the pressure to 0.2Mpa, and reacting for 4 hours under stirring;

[0034] (3) Add water in proportion to the system of step (2), and stir for 15 minutes to obtain a steel slag activator.

[0035] The preparation method of the steel slag powder activated material containing the above-mentioned steel slag activator includes the following steps:

[0036] (1) Add 4w% water to the existing steel slag, and then grind, and add 0.02wt% of the steel slag activator dropwise during the grinding process; t...

Embodiment 2

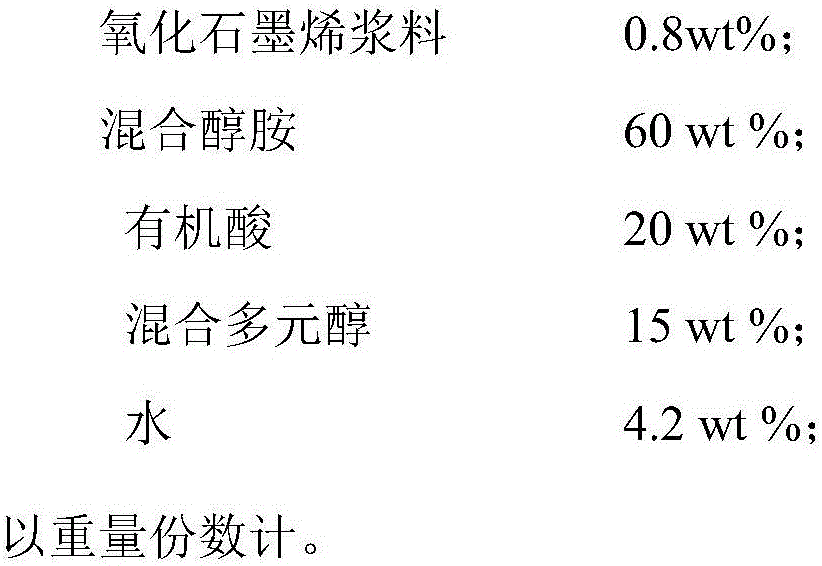

[0043] Embodiment 2: A steel slag activator, including the following components:

[0044]

[0045]

[0046] The preparation method of the above-mentioned steel slag activator includes the following steps:

[0047] (1) Put the mixed alcohol amine, organic acid and mixed polyol into the reaction kettle in proportion, control the temperature at 30~35℃, and react for 4h under stirring conditions;

[0048] (2) Add graphene oxide slurry to the system of step (1), while raising the temperature to 100°C, adjusting the pressure to 0.25Mpa, and reacting for 3 hours under stirring;

[0049] (3) Add water in proportion to the system in step (2), and stir for 10 minutes to obtain a steel slag activator.

[0050] The preparation method of the steel slag powder activated material containing the above-mentioned steel slag activator includes the following steps:

[0051] (1) Add 3w% of water to the existing steel slag, then grind, and add 0.015wt% of the steel slag activator dropwise during the grinding ...

Embodiment 3

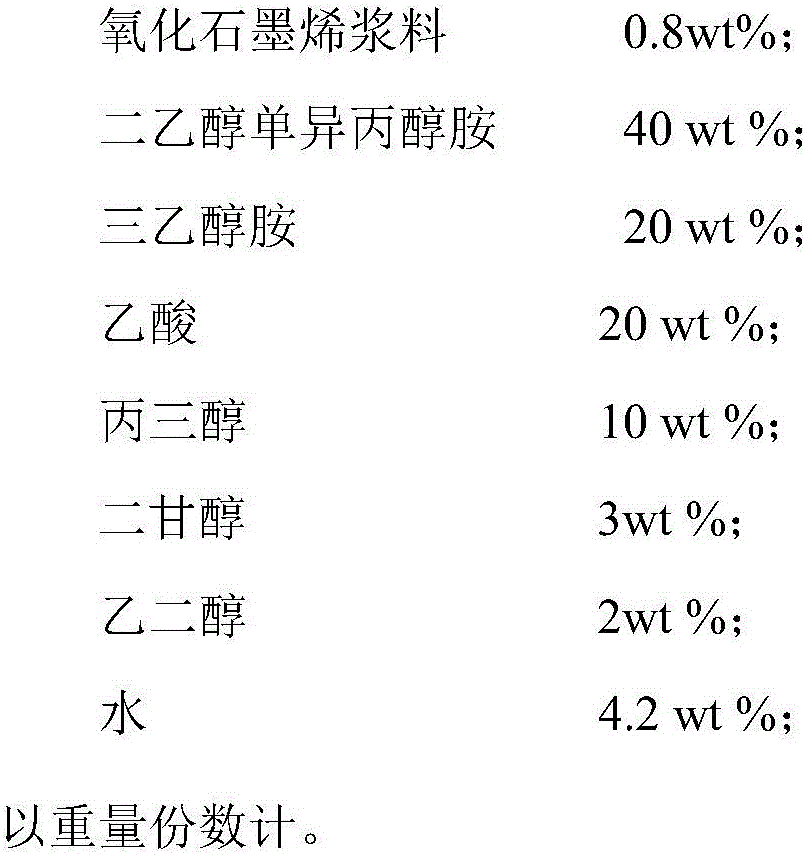

[0053] Embodiment 3: A steel slag activator, including the following components:

[0054]

[0055]

[0056] The preparation method of the above-mentioned steel slag activator includes the following steps:

[0057] (1) Put the mixed alcohol amine, organic acid and mixed polyol into the reaction kettle in proportion, control the temperature at 45~50℃, and react for 3h under stirring conditions;

[0058] (2) Add graphene oxide slurry to the system of step (1), while raising the temperature to 150°C, adjusting the pressure to 0.4Mpa, and reacting for 6 hours under stirring;

[0059] (3) Add water in proportion to the system in step (2), and stir for 30 minutes to obtain a steel slag activator.

[0060] The preparation method of the steel slag powder activated material containing the above-mentioned steel slag activator includes the following steps:

[0061] (1) Add 5w% water to the existing steel slag, and then grind, and add 0.03wt% of the steel slag activator dropwise during the grinding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com