Special rock wool for micro-landscape sculptures

A micro-landscape and rock wool technology, applied in the field of landscape, can solve the problems of reduced sheet strength, weather resistance and structural damage, insufficient fiber softness, etc., to achieve the effect of enhanced softness, weather resistance and corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of rock wool specially used for micro-landscape carving, which is composed of the following components in mass percentage: Al2O3 20%, CaO 16%, MgO 10%, TiO2 1.2%, MnO 0.03%, P2O5 0.04%, SrO 0.03%, Na2O 0.2%, K2O 0.5%, SiO2 41%, impurity 2%, total iron content 9%. It should be noted that, in the above ratio, the total iron content is 9%, that is, the total content of the three components of FeO, Fe2O3 and iron is 9%. Of course, it can also be one or both of FeO, Fe2O3 and iron.

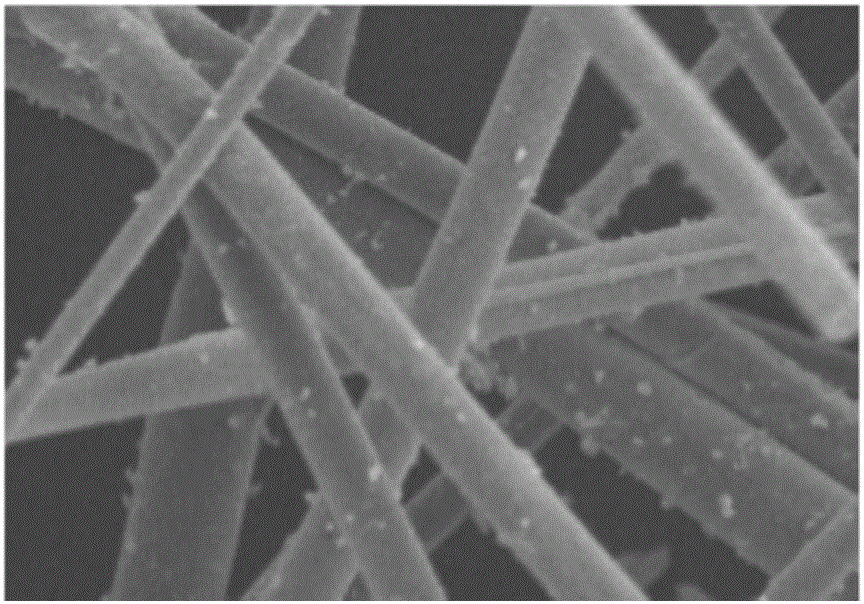

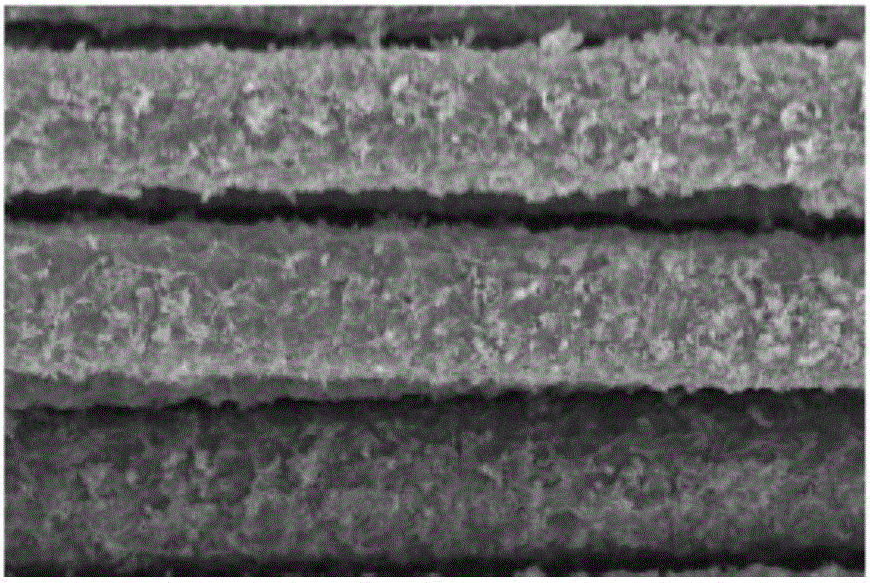

[0019] The rock wool specially used for micro-landscape carving of the present invention has an average fiber diameter of 2.5-4 μm as measured by the GB25975-2010 fiber diameter detection method; it is relatively thinner than the existing rock wool fiber average diameter, and in addition, it is also obviously Improved flexibility. In terms of corrosion resistance, the rock wool special for rock wool micro-landscape carving of the present invention and the existing glass fiber are soaked...

Embodiment 2

[0022] The rock wool dedicated to micro-landscape carving in this embodiment has the same components as the rock wool dedicated to micro-landscape carving in Example 1, and the difference between the two is only in the content of the components. Specifically, it consists of the following components by mass percentage: Al2O3 17~25%, CaO 15~20%, MgO 7~15%, TiO2 1~3%, MnO 0.01~0.9%, P2O5 0.01~0.9%, SrO 0.01 ~0.9%, Na2O 0.01~0.4%, K2O 0.1~2%, SiO2 30-55%, impurities 0~5%, total iron content 4~17%. The rock wool dedicated to micro-landscape sculpture with this component content has a finer fiber average diameter than the existing glass fiber, and its corrosion resistance is also improved. In addition, the rock wool dedicated to micro-landscape sculpture with this component ratio The fiber diameter is thinner, and the softness of the fiber is improved at the same time, so it is suitable for cutting without producing skin itching feeling during the cutting process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com