A valveless rapid sand filter deep treatment buried integrated sewage treatment method

A sewage treatment method and advanced treatment technology, applied in water/sewage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the inconvenient management and operation of sewage treatment system, buried sewage treatment system The quality of filtered water is difficult to meet the treatment standard, and the suspended solids exceed the standard, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described with reference to the accompanying drawings.

[0016] A valveless fast sand filter deep treatment buried integrated sewage treatment method according to the present invention comprises the following methods:

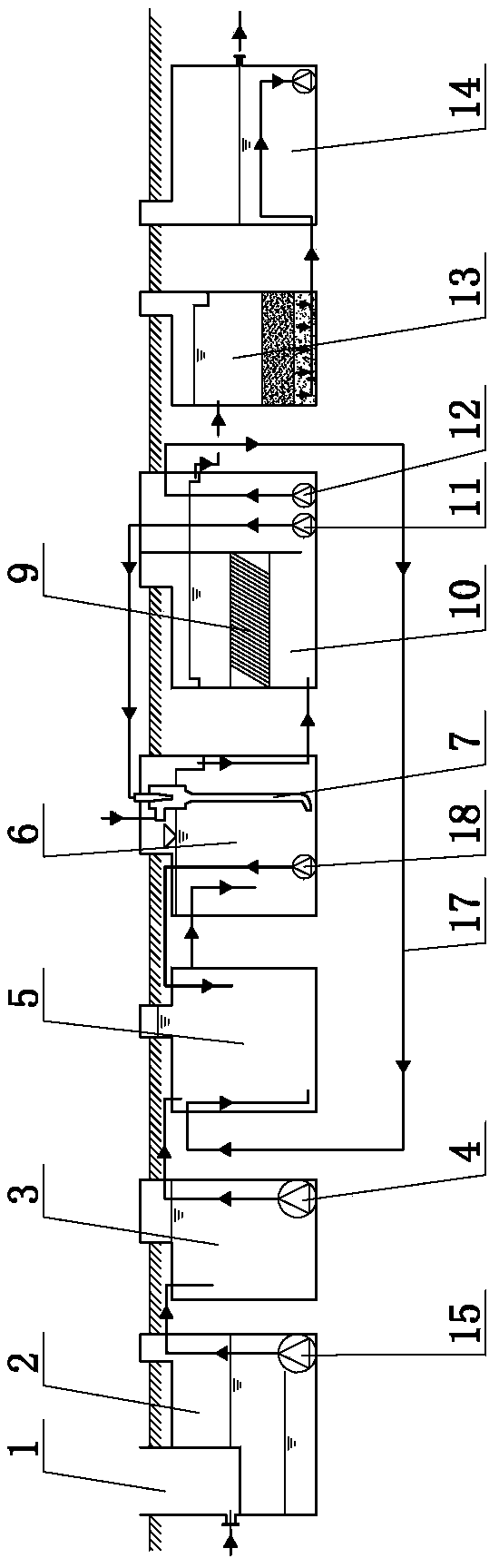

[0017] ① Set the grille pool 1, water collection pool 2, regulating pool 3, anoxic pool 5, aerobic pool 6, secondary sedimentation pool 10, sand filter 13 and clear water pool 14 below the ground surface, and the pool mouth of the grille pool 1 It is flush with the ground surface, which is convenient for water intake, and other pools are provided with vents;

[0018] ②Install the sump lifting pump 15 at the bottom of the sump 2, install the regulating pool hoist pump 4 at the bottom of the regulating pool 3, install the jet device 7 in the aerobic pool 6, install the inclined tube settling tray 9 in the middle of the secondary sedimentation tank 10, and install the 10. A jet pump 11 and a mixed liquid and sludge ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com