Method for preparing calcium oxide and sulfur from gypsum and system device

A system device, calcium oxide technology, applied in chemical instruments and methods, calcium/strontium/barium oxide/hydroxide, inorganic chemistry, etc., can solve problems such as gypsum environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The gypsum raw material is desulfurized gypsum from somewhere, and its main components are as follows:

[0062] composition SiO 2

Al 2 o 3

Fe 2 o 3

CaO MgO Na 2 o

K 2 o

SO 3

crystal water other content% 1.93 0.49 0.21 31.45 0.65 0.06 0.15 45.23 18.26 1.57

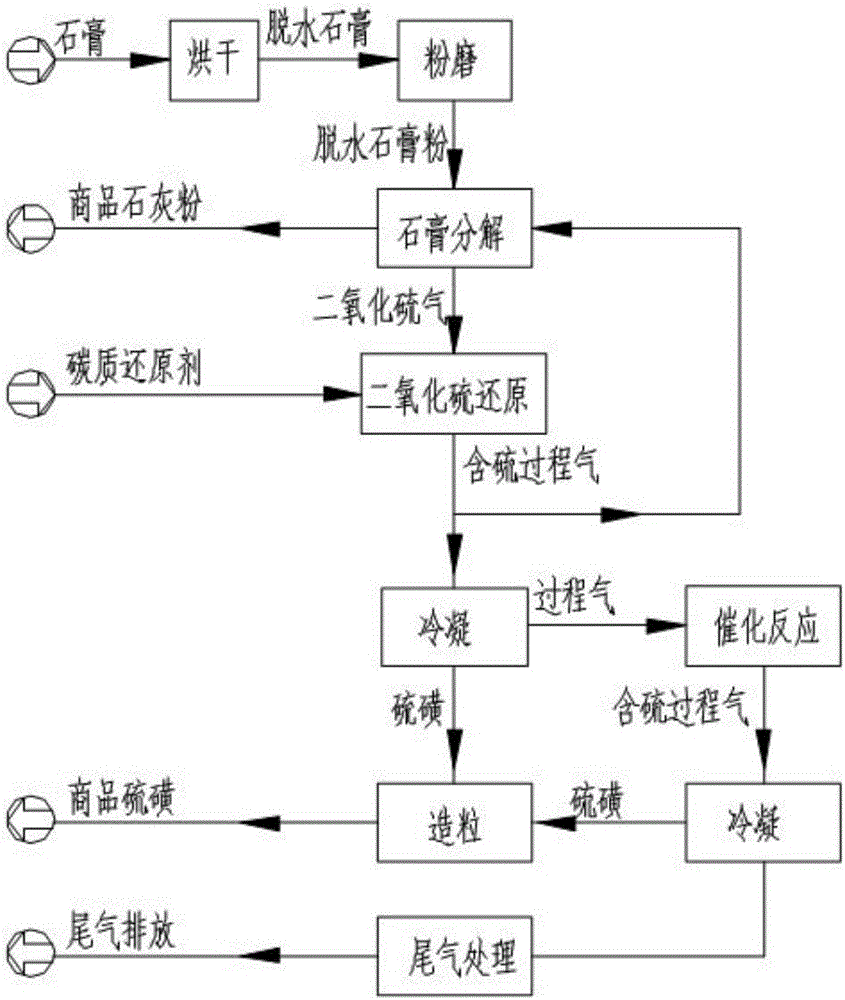

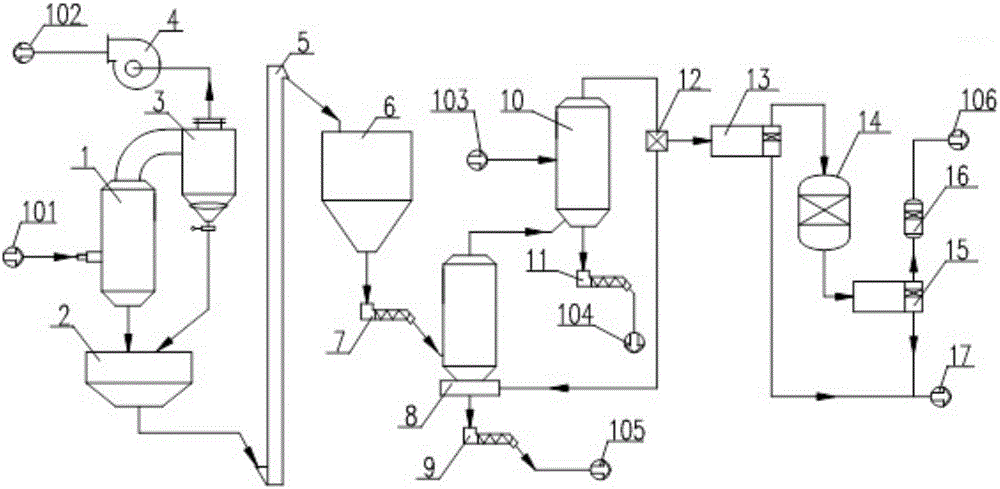

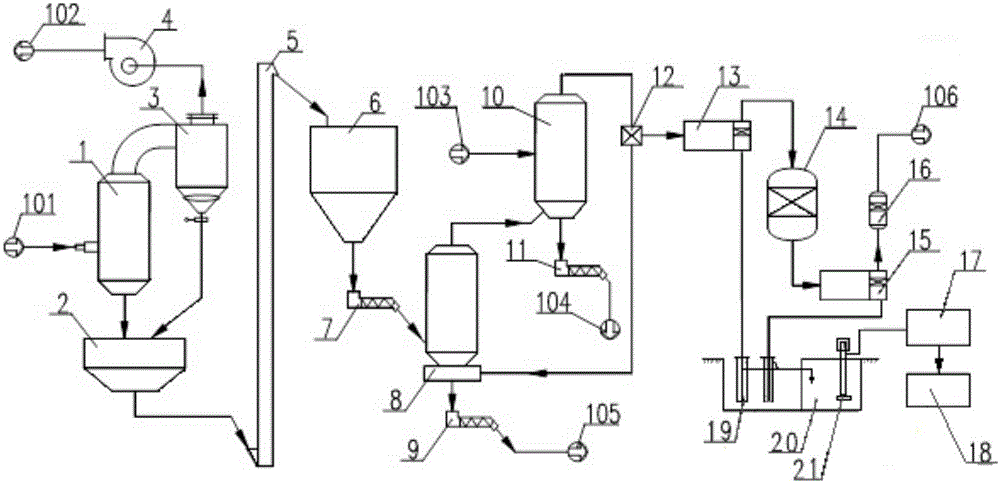

[0063] The method of producing calcium oxide and sulfur from gypsum is to contact and react gypsum with sulfur-containing process gas at high temperature to obtain calcium oxide and sulfur dioxide, and then react sulfur dioxide with a carbonaceous reducing agent to produce sulfur, such as figure 1 As shown, it specifically includes the following steps:

[0064] (1) Gypsum pretreatment: remove impurities first and then dry and dehydrate the dihydrate gypsum. The drying temperature is 90°C and the drying time is 8 hours. The total water content of the dehydrated gypsum after drying and dehydration is 2-8%. Grinding device to produce dehydrate...

Embodiment 2

[0069] The gypsum raw material is desulfurized gypsum from somewhere, and its main components are as follows:

[0070] composition SiO 2

al 2 o 3

Fe 2 o 3

CaO MgO Na 2 o

K 2 o

SO 3

crystal water other content% 1.93 0.49 0.21 31.45 0.65 0.06 0.15 45.23 18.26 1.57

[0071] The method for preparing calcium oxide and sulfur from gypsum is to contact and react gypsum with sulfur-containing process gas at high temperature to obtain calcium oxide and sulfur dioxide, and then react sulfur dioxide with a carbonaceous reducing agent to prepare sulfur, which specifically includes the following steps:

[0072] (1) Gypsum pretreatment: remove impurities first and then dry and dehydrate the dihydrate gypsum. The drying temperature is 150°C and the drying time is 5 hours. The total water content of the dehydrated gypsum after drying and dehydration is 2-10%. device to produce dehydrated gypsum powder with an average...

Embodiment 3

[0077] The gypsum raw material is desulfurized gypsum from somewhere, and its main components are as follows:

[0078] composition SiO 2

al 2 o 3

Fe 2 o 3

CaO MgO Na 2 o

K 2 o

SO 3

crystal water other content% 1.93 0.49 0.21 31.45 0.65 0.06 0.15 45.23 18.26 1.57

[0079] The method for preparing calcium oxide and sulfur from gypsum is to contact and react gypsum with sulfur-containing process gas at high temperature to obtain calcium oxide and sulfur dioxide, and then react sulfur dioxide with a carbonaceous reducing agent to prepare sulfur, which specifically includes the following steps:

[0080] (1) Gypsum pretreatment: remove impurities first and then dry and dehydrate the dihydrate gypsum. The drying temperature is 200°C and the drying time is 2 hours. The total water content of the dehydrated gypsum after drying and dehydration is 2-10%. device to produce dehydrated gypsum powder with an average...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com