Device for synthesizing nano particles through glow discharge and synthesis method thereof

A nanoparticle, glow discharge technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of unsustainable discharge time, large particle size fluctuations, low preparation efficiency, etc., and improve the size controllability. , The effect of large local thermal effect and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

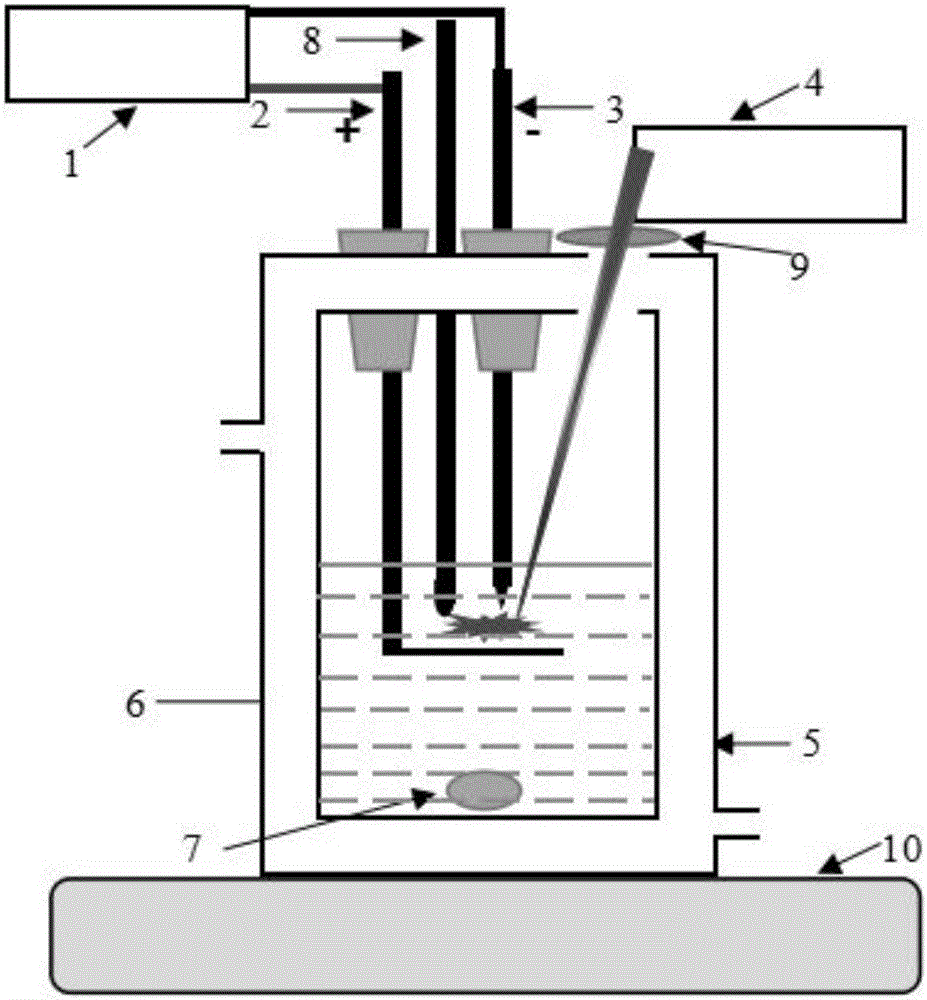

[0042] Use 300V, 3A direct current source, nanosecond laser, silver nano solution, graphite electrode and platinum sheet electrode pair to make titanium dioxide nano solution.

[0043] 1. Prepare the electrolyte: first pour 30ml of nano silver solution, 20ml of distilled water, and 0.1g of titanium dioxide powder into the electrolytic cell, turn on the magnetic stirring heater and rotate the stirring magnet at 1000 revolutions / min. The stirring time is 20 minutes. The concentration of the obtained nano silver solution is 1000 ppm, and the particle size of the silver nano particles is 10 nm.

[0044] 2. Make the electrode pair: After the solution is evenly stirred, put the electrode pair into the electrolytic cell. The electrode anode used here is a platinum sheet, the size of the platinum sheet is 10mm*10mm*1mm, and the cathode uses graphite electrodes and graphite rod-shaped electrodes. It is Φ5mm*10cm, and the end of the graphite electrode is ground into a Φ0.1mm fine graphite ti...

Embodiment 2

[0051] Use 800V, 5A pulse source, picosecond laser, copper nano solution, graphite electrode and copper sheet electrode pair to make titanium dioxide nano solution.

[0052] 1. Preparation of electrolyte: in figure 1 First, pour 30ml of nano-copper solution, 20ml of distilled water, and 0.1g of titanium dioxide powder into the electrolytic cell, turn on the magnetic stirring heater and rotate the stirring magnet at 1000 revolutions / min. The stirring time is 20 minutes. The concentration of the solution is 5000 ppm, and the particle size of copper nanoparticles is 10 nm.

[0053] 2. Make the electrode pair: After the solution is evenly stirred, put the electrode pair into the electrolytic cell. The electrode anode used here is a copper sheet. The copper sheet specification is 20mm*20mm*2mm. The cathode uses graphite electrodes and graphite rod electrodes. The specification is Φ5mm*10cm, and the end of the graphite electrode is ground into a Φ0.1mm fine graphite tip. Except for the 3...

Embodiment 3

[0060] Use 800V, 5A pulse source, picosecond laser, silver nano solution, graphite electrode and copper sheet electrode pair to make titanium dioxide nano solution.

[0061] 1. Preparation of electrolyte: in figure 1 First, pour 30ml of nanocopper solution, 20ml of distilled water, and 0.1g of titanium dioxide powder into the electrolytic cell, turn on the magnetic stirring heater and rotate the stirring magnet at 1000 revolutions / min. The stirring time is 20 minutes. The concentration of the solution is 1000 ppm, and the particle size of silver nanoparticles is 10 nm.

[0062] 2. Make the electrode pair: After the solution is evenly stirred, put the electrode pair into the electrolytic cell. The electrode anode used here is a copper sheet, the copper sheet specification is 20mm*20mm*2mm, the cathode uses a graphite electrode, and the graphite rod electrode specification It is Φ5mm*10cm, and the end of the graphite electrode is ground into a Φ0.1mm fine graphite tip. Except for the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com