Adjustable FPC (Flexible Printed Circuit) laminating machine material taking mechanism with target identification function

A technology of target recognition and reclaiming mechanism, applied in the field of adjustable FPC laminating machine reclaiming mechanism, can solve the problems of low production efficiency, high production cost, high strength, etc., and achieve easy replacement, high degree of automation, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

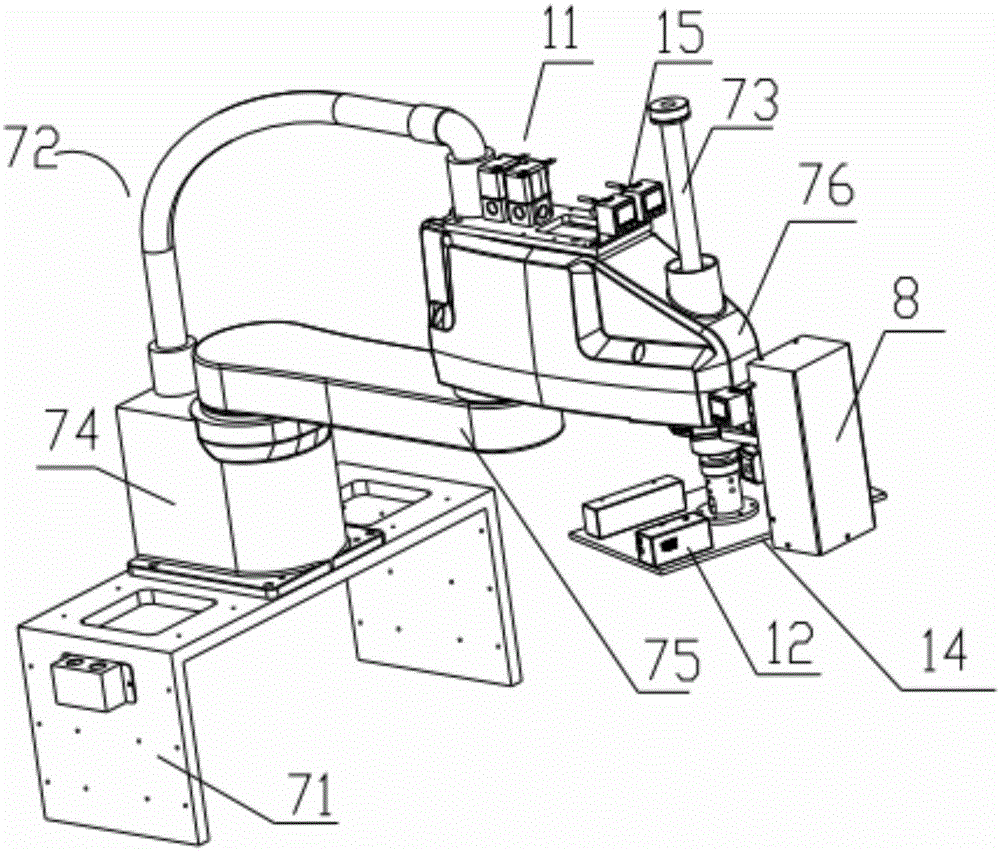

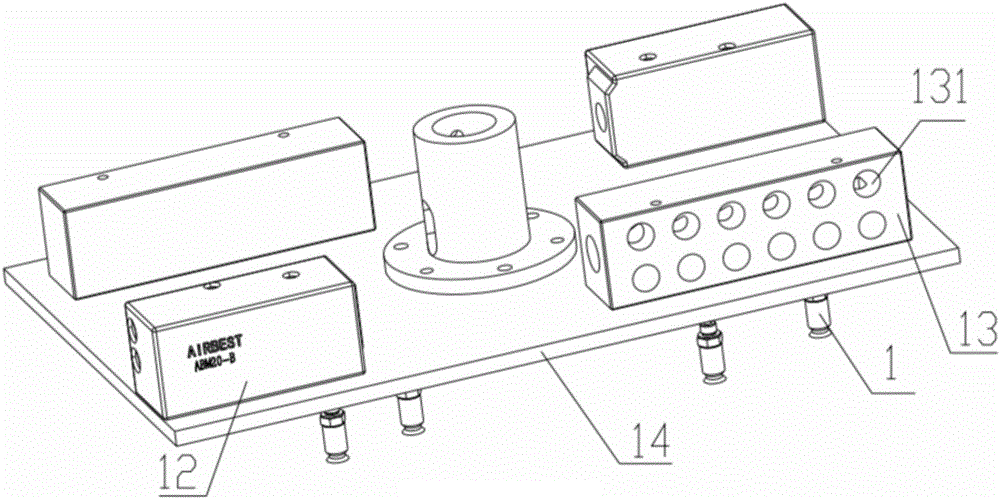

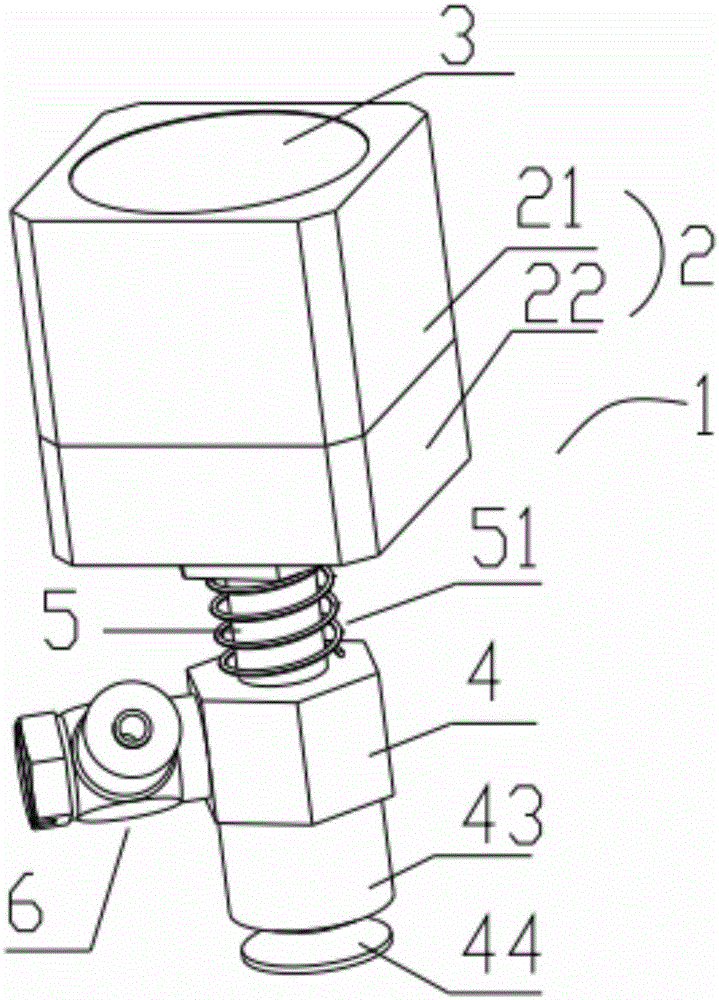

[0032] From Figure 1 to Figure 4 As can be seen from the illustrated embodiment of the present invention, the adjustable FPC laminating machine reclaiming mechanism with target recognition function includes a base 71, a manipulator 72 arranged on the base 71, a lifting rod 73, a suction tray and a position Capture device 8. Manipulator 72 comprises base 74, the first rocking arm 75 and the second rocking arm 76 that are fixed on the base 71, and one end of first rocking arm 75 is hinged on base 74 and the other end is hinged on an end of second rocking arm 76, lifts The rod 73 is movably connected to the other end of the second rocking arm 76, and the position capturing device 8 is a camera arranged at the end of the manipulator, which is a CCD high-precision camera in the present invention. Through the rotation of the first rocker arm 75 and the second rocker arm 76, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com