Supporting roller set mechanism with line deflection preventing function

A technology for idler groups and anti-deviation, which is applied in the direction of rollers, conveyors, and conveyor objects. It can solve the problems of difficult disassembly and replacement, failure to meet the needs of working conditions, and complex structure of the deviation correction mechanism. It is easy to use, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

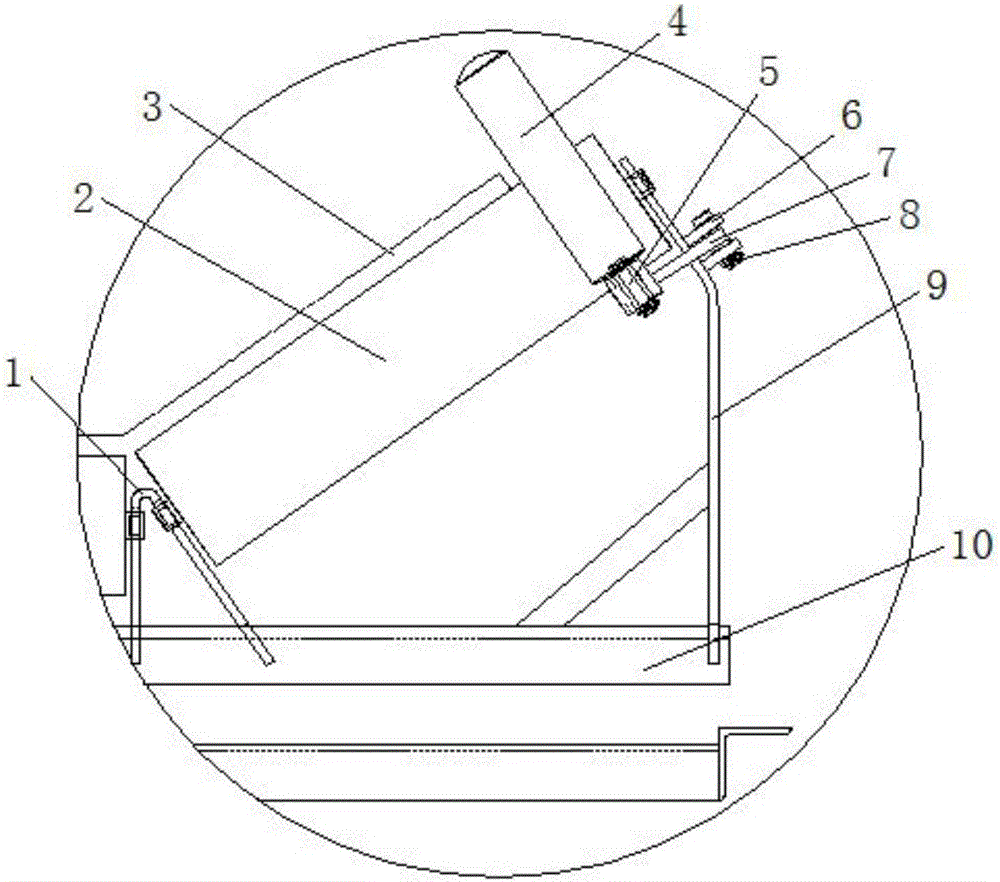

[0012] An idler group mechanism with anti-deviation function, such as figure 1 As shown, the idler roller set includes a roller bracket 9 and a bracket 1 for installing the roller 2, the roller bracket 9 and the bracket 1 are installed on the top beam 10, the roller 2 carries the conveyor belt 3, and the conveyor belt 3 is equipped with deviation correction parts on both sides , used to prevent and correct the deviation of the conveyor belt 3;

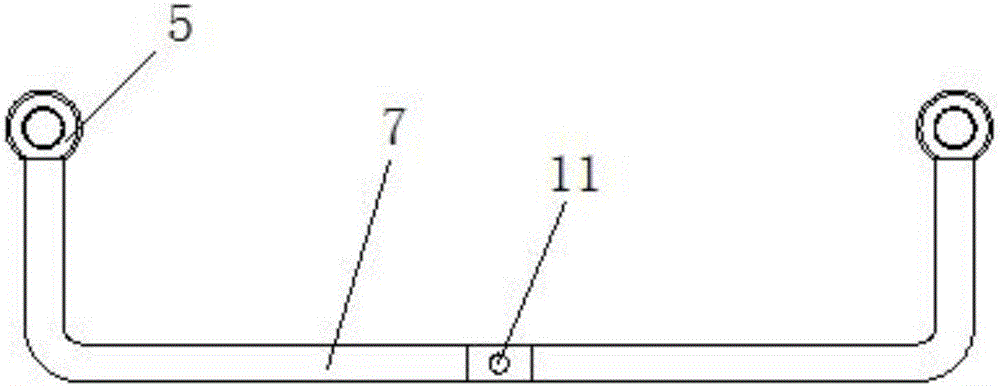

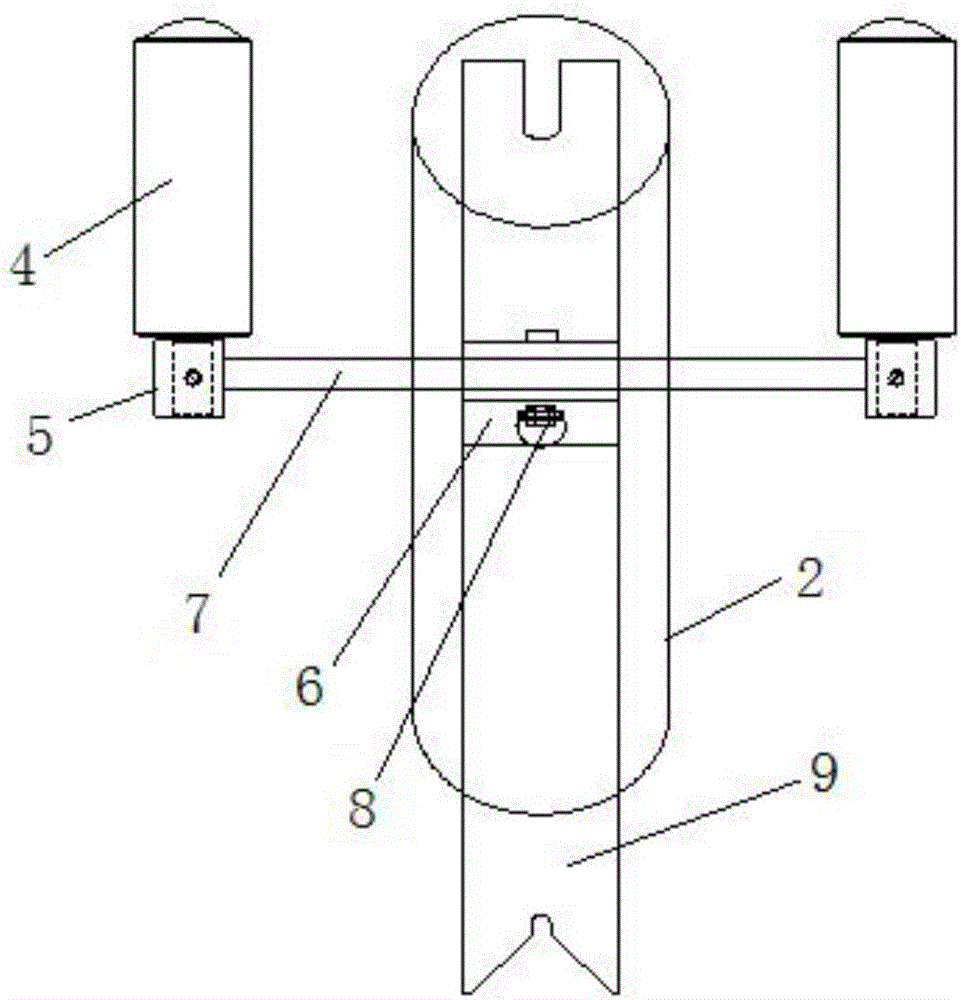

[0013] The deviation correction part includes deviation correction roller 4, steel sleeve 5, side plate 6, rotating shaft 7 and pin shaft 8; see figure 2 , the two ends of the rotating shaft 7 are bent 90 degrees to the same side to form a U-shaped rod body. A steel sleeve 5 is respectively provided at both ends of the bent rotating shaft 7, and a through hole 11 is provided in the middle;

[0014] The two opposite side plates 6 are vertically welded on the outside of the bent end of the roller bracket 9, and the two side plates are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com