Battery box transmission system for pole group pressing procedure

A transfer system and battery box technology, which is applied in the construction of secondary batteries, lead-acid batteries, and lead-acid batteries, can solve the problems of low efficiency, poor precision, and high labor intensity of lead-acid batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

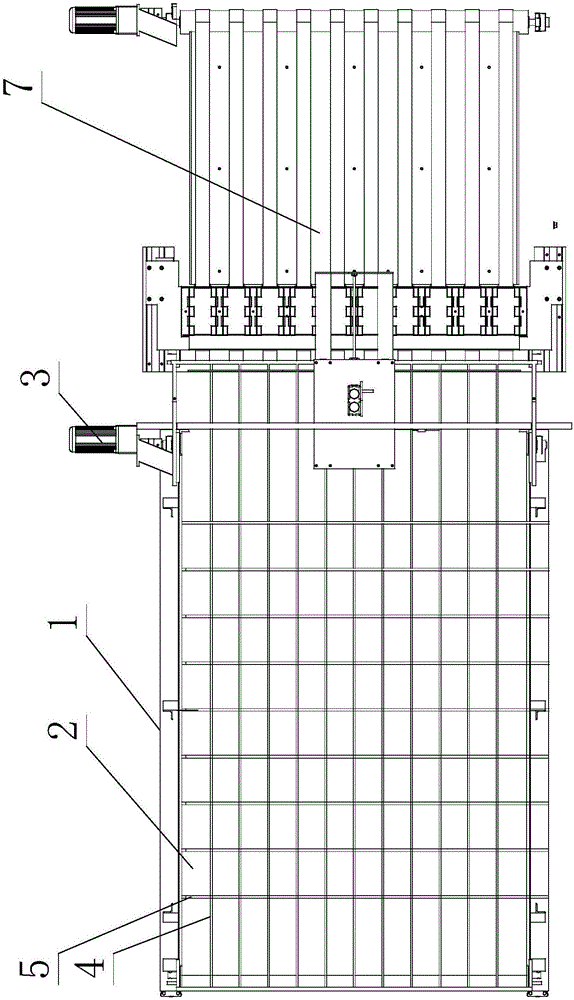

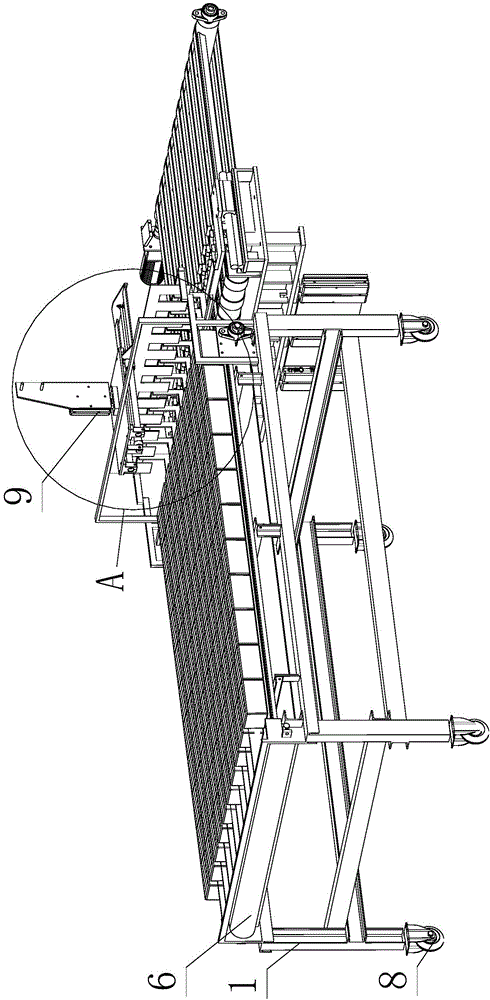

[0037] Such as Figure 1 to Figure 8 As shown, the battery box transfer system used for the electrode group pressing process includes a primary transmission part and a secondary transmission part 7 located at the output end of the primary transmission part. The first conveyor belt 2 on the first frame 1, the pulley 6 for the installation of the first conveyor belt 2, and the braking device for braking the rotation of the pulley 6, the first-stage transmission part also includes 2 the box unloading part 9 above the discharge end, the box unloading part 9 is used to further accelerate the battery box on the first conveyor belt 2 so as to output the battery box to the secondary transmission part 7;

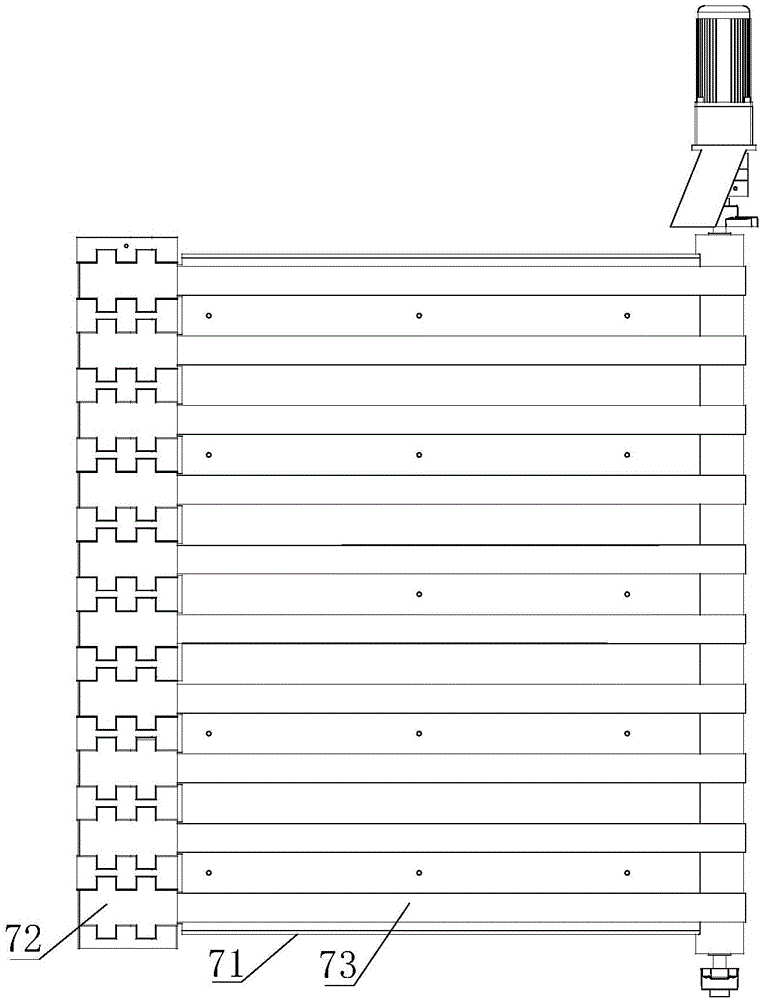

[0038] Described second transmission part comprises second frame 71 and the second conveyor belt 73 that is arranged on the second frame 71, and second transmission part also comprises the shelving platform 72 that is arranged on the feed end of second conveyor belt 73 and is positio...

Embodiment 2

[0043] Such as Figure 1 to Figure 8As shown, this embodiment is further limited on the basis of embodiment 1: in order to realize that the system can transfer multiple battery boxes at the same time or perform pole group pressing operations on multiple battery boxes at the same time, and at the same time, in order to facilitate the realization of the communication function The action consistency of parts is beneficial to the material and process control in the production process of lead-acid batteries. The second conveyor belt 73, the shelving table 72 and the tray table 75 are more than one and the number of the three is equal. The second conveyor belt 73 is mutually 1. The shelving tables 72 and the tray trays 75 are arranged in parallel rows, and the second conveyor belt 73 is installed on the same pulley 6 groups. The trays 72 and the tray trays 75 are all Arranged side by side at the feed end of the second frame 71;

[0044] Simultaneously as a kind of structural form o...

Embodiment 3

[0051] This embodiment is further limited on the basis of the technical solution provided in embodiment 1, as Figure 1 to Figure 8 , as a way to adapt to the shape of the bottom surface of the existing battery box and to ensure that both the shelving table 72 and the tray table 75 can stably support the battery box, the said shelving table 72 is parallel to the second conveyor belt 73 in the length direction In the shape of a rectangular parallelepiped in the conveying direction, at least one notch is provided on both width sides of the shelving table 72 , and protrusions corresponding to each notch are provided on the inner walls of both sides of the groove-like structure. That is, the structural form of the above tray table 75 can support both sides of the length side of the battery case.

[0052] Because the shelving platform 72 is delivered to the receiving part of the secondary transmission part 7 as the battery box, and the relative positions and respective structures a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com