Method for manufacturing plastic manifold of miniature vehicle engine air intake system

A technology of air intake system and intake manifold, which is applied in the field of preparation of intake manifolds, can solve the problems of inability to realize product matching production, large mold volume, poor production efficiency, etc., and achieve ingenious design, good comprehensive performance, and high efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

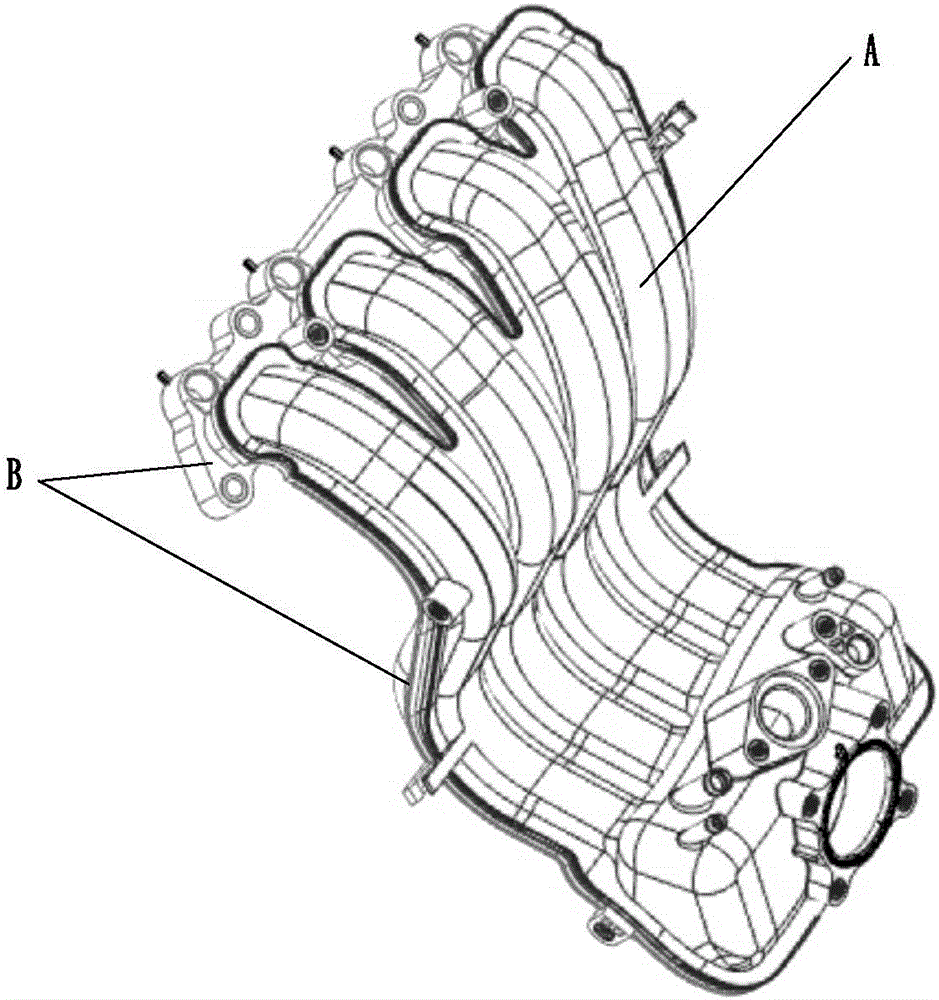

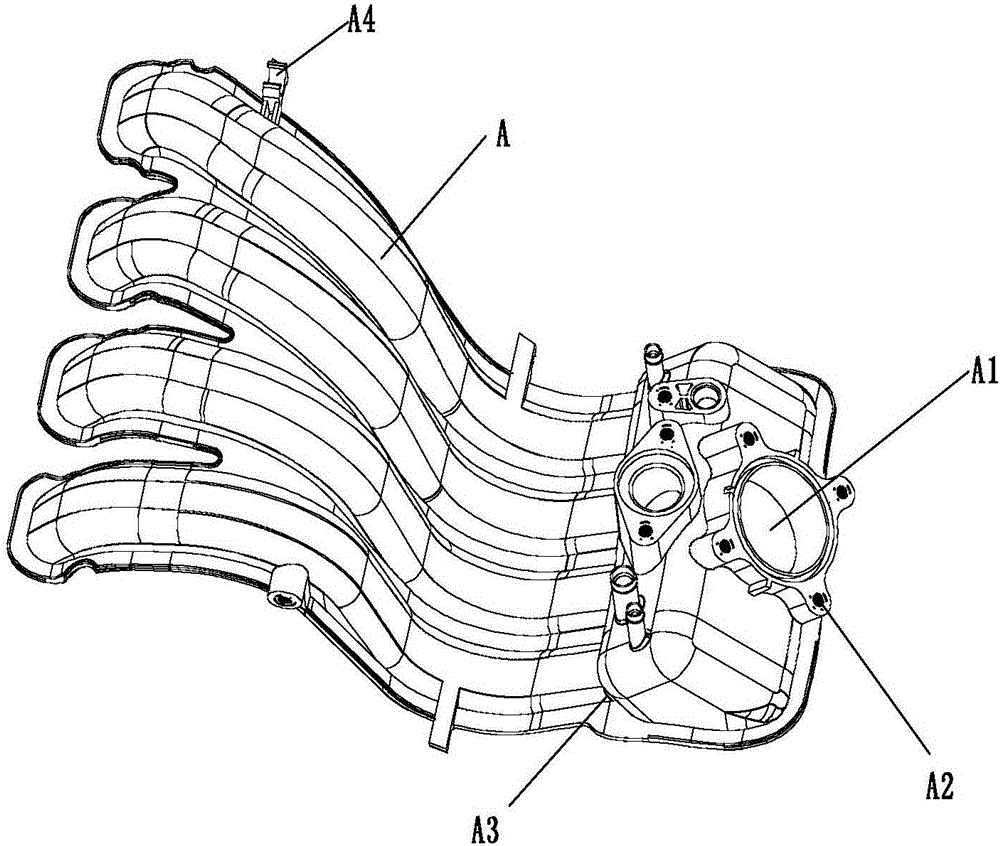

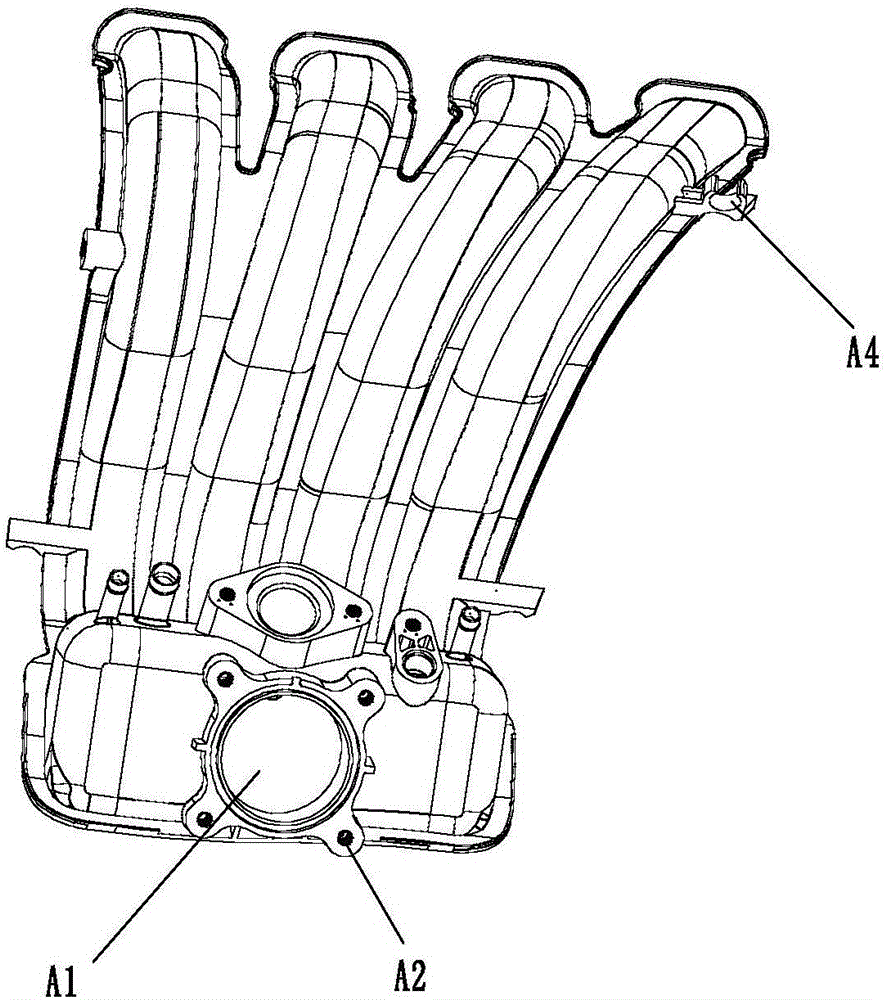

[0039] Embodiment 1: A preparation method of a plastic manifold for an engine air intake system of a miniature car, including an injection molding process and a friction welding process, and the injection molding process uses a molding die to prepare the upper part of the intake manifold and the intake manifold. For the lower part of the manifold, the friction welding process is to weld the upper part of the intake manifold and the lower part of the intake manifold together by means of friction welding.

[0040] The molding die includes a front mold 1 and a rear mold 2, and the front mold is provided with a guide post 111, an oblique guide post 13 at the upper part of the manifold, an oblique guide block 15 at the lower part of the manifold, and an oblique guide block 15 at the outlet port of the manifold. The nut on the upper side is embedded in the inclined guide post 14, the nut on the lower side of the manifold is embedded in the inclined guide post 19, the nut on the lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com