Charging pipe positioning component and rotary expanding tool and clamping and positioning method of gem element

A technology for positioning components and rotary expansion tooling, which is applied in the field of tooling and fixtures, can solve the problems of large positioning errors of material tubes, increased production costs, and large amount of top cores, and achieves the effects of improved positioning accuracy, convenient operation, and saving top cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

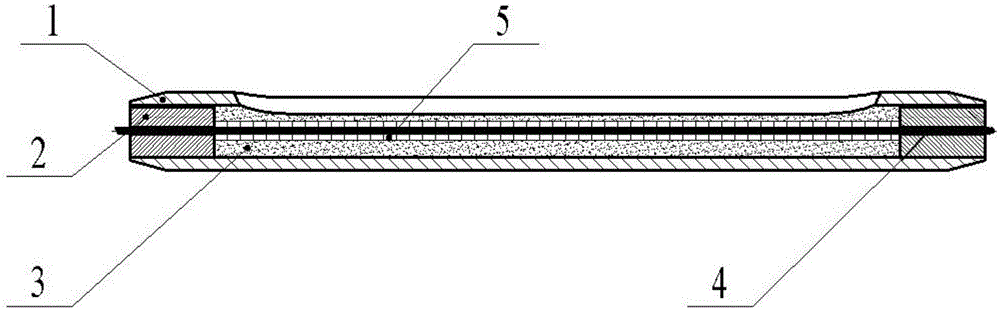

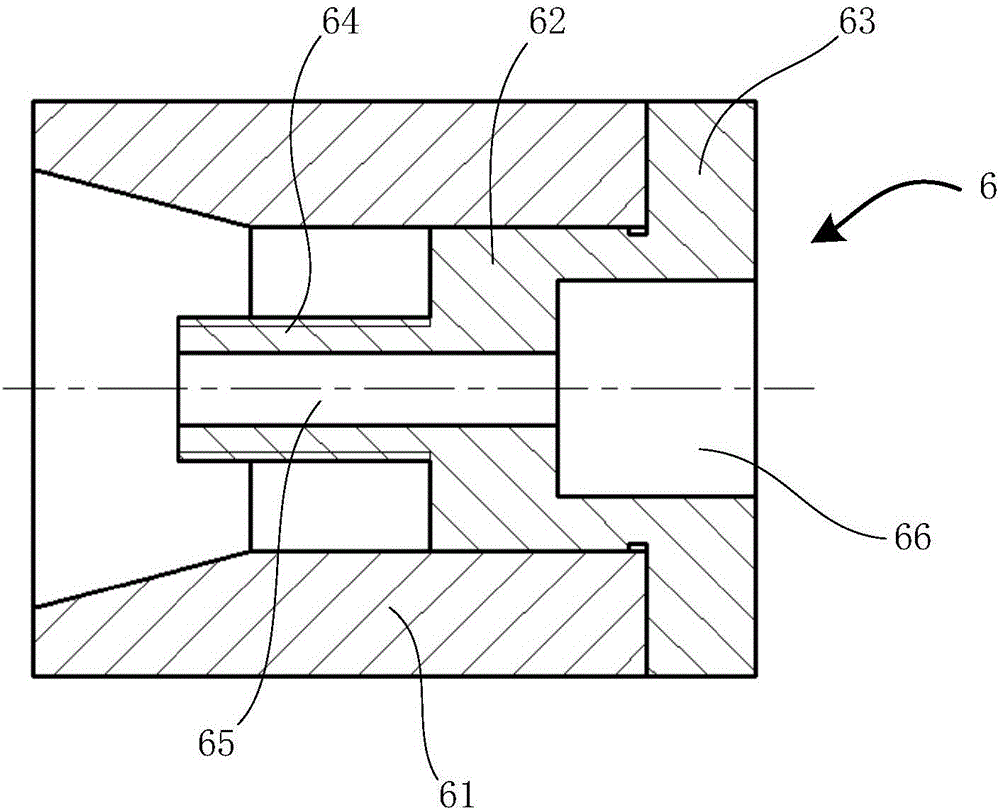

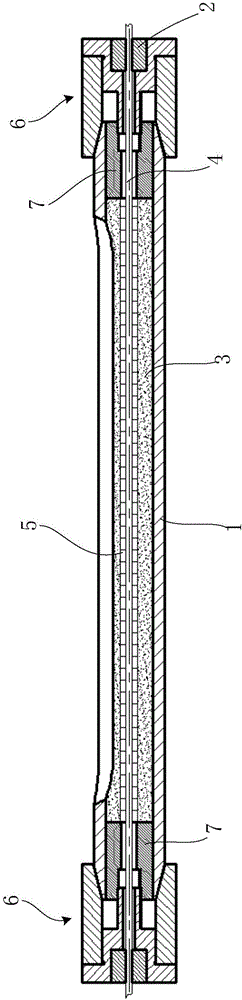

[0041] Such as figure 2 As shown, a material tube positioning assembly 6 is used for positioning a material tube with an outer cone, including a positioning sleeve 61 and a positioning seat 62, and the positioning seat 62 presses the positioning sleeve 61 on the outer cone surface of the material tube in the axial direction, And the end of the positioning sleeve 61 is provided with an inner conical surface that cooperates with the outer conical surface of the material tube, and the center of the positioning seat 62 is provided with a through hole 65, so that steel wires etc. pass through, and the inner end of the positioning seat 62 is provided with a connector 64, the connector 64 extends into the positioning sleeve 61 for direct or indirect connection with the material pipe. The outer end of the positioning seat 62 is provided with a mounting hole 66 for installing the top core. The inside and outside described in this example are based on the end close to the material pipe....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com