A reusable flameproof socket

A flame-proof and flame-proof technology, applied in the parts of connecting devices, coupling devices, fixed/insulating contact members, etc., can solve the problem of non-reusable models of insulators, and achieve the effect of filling and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

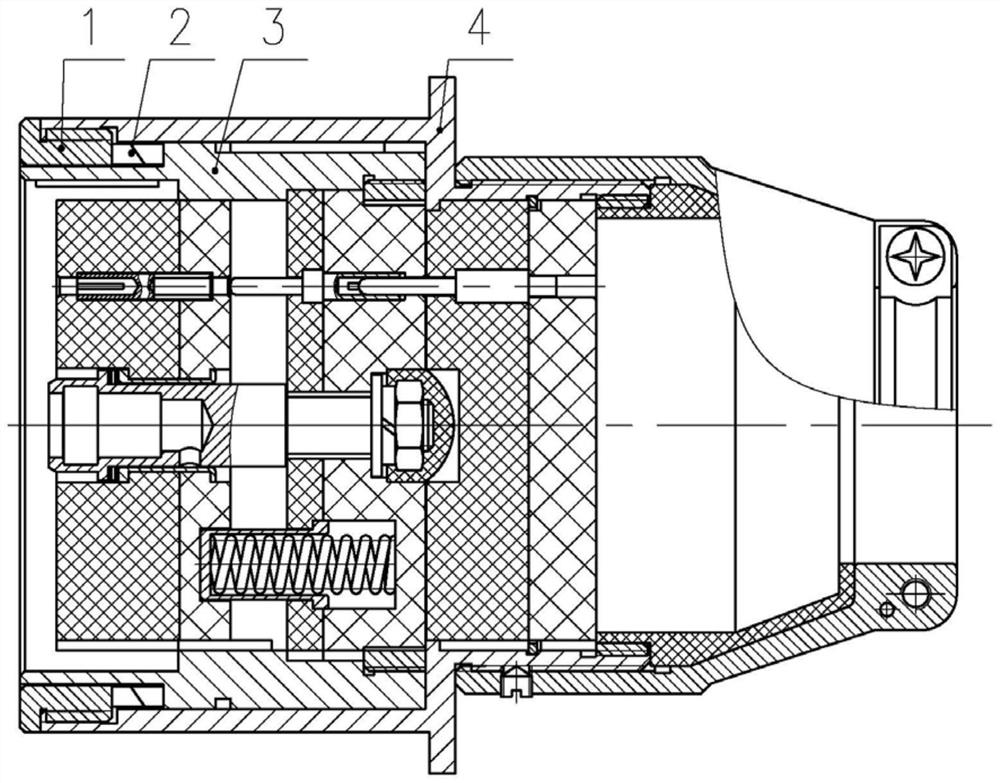

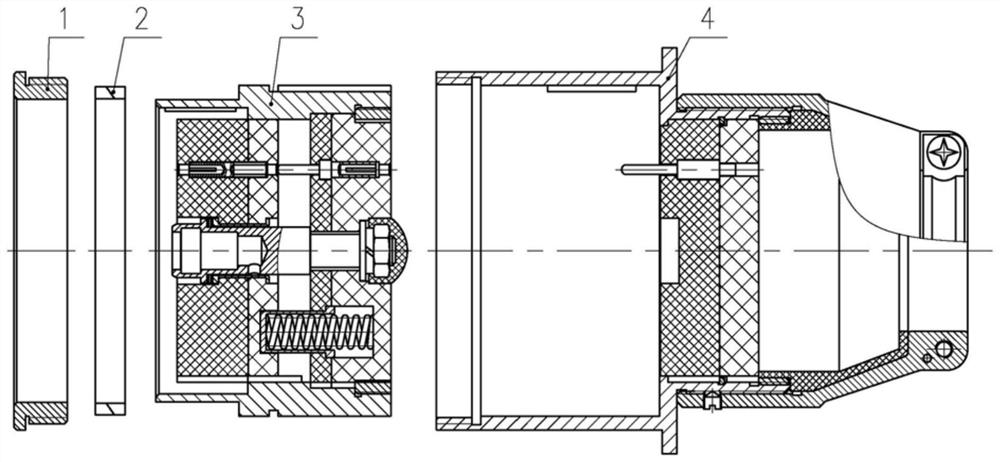

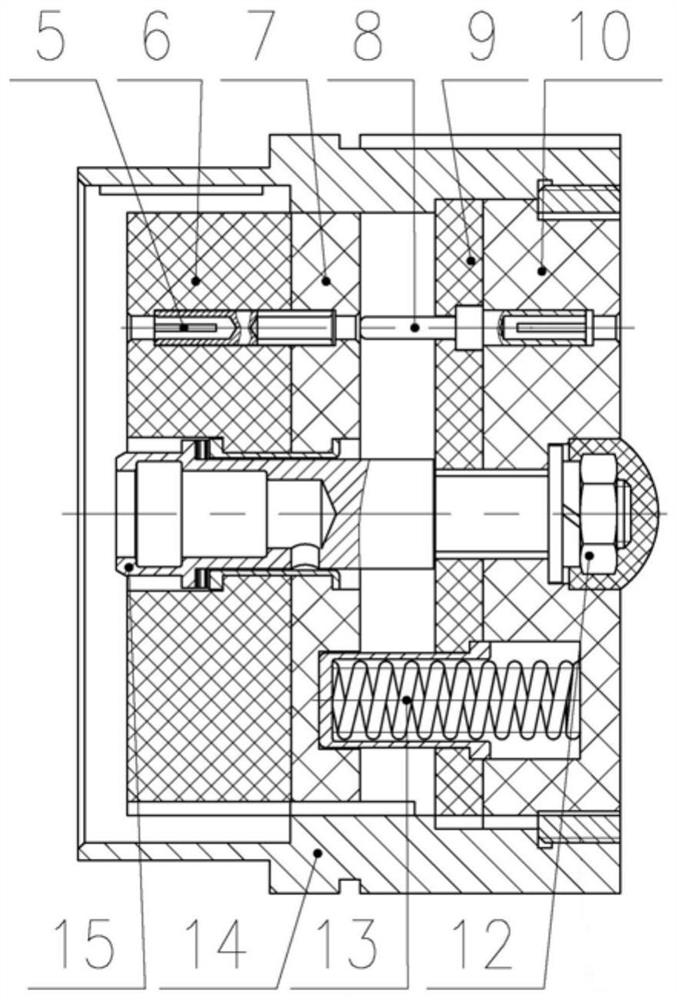

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0023] The invention provides a reusable flame-proof socket. When the plug of the separated electrical connector is separated from the socket, the plug-in end of the socket is subjected to the action of high-temperature flames, and the flame-proof layer and the protective layer assembly of the socket are pushed by the elastic force of the spring 13 to prevent The disconnection of the contact between the flame layer and the protective layer realizes the anti-short circuit function of the flameproof layer and the protective layer; through the insulator material of the flameproof layer, the high temperature heat insulation effect is realized; through the insulator material of the protective layer, the locking sleeve 15 is realized. Fixed function, anti-short circuit function between 8 pin holes and protection to the back layer; the socket is a detac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com