Phase change heat storage test device and phase change heat storage test method

A technology of phase change heat storage and temperature measuring device, which is applied in the field of building energy storage and energy saving, can solve the problems of lack of substantial research on the amount of phase change materials and the change of the internal temperature of phase change materials during heating time, and achieve a clear test principle and test The result is intuitive and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

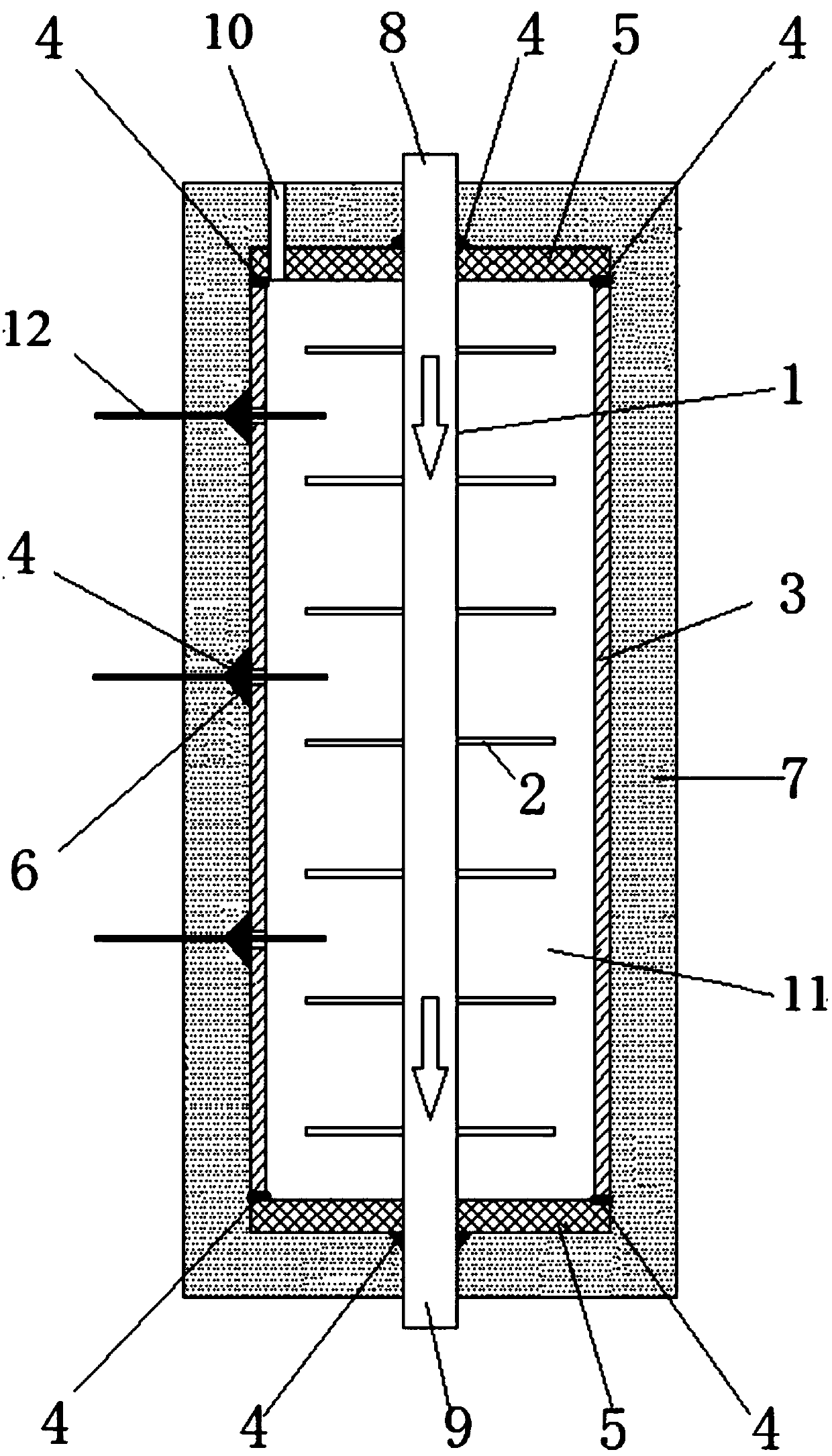

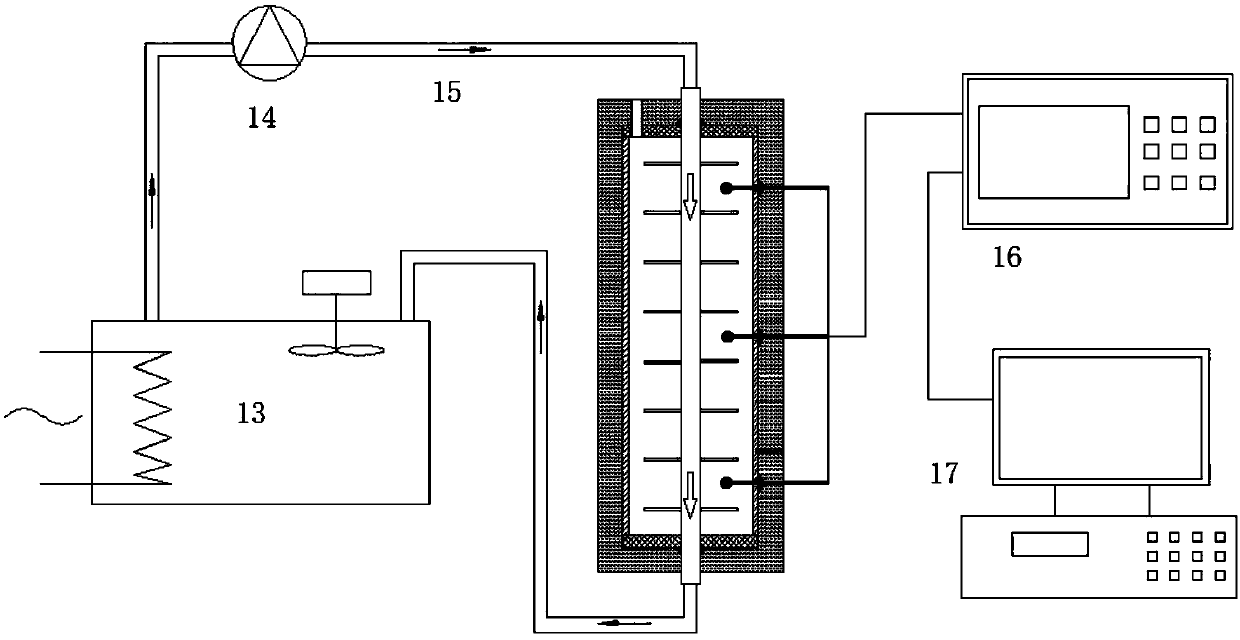

[0014] Such as figure 1 , figure 2 As shown, the phase change heat storage temperature measuring device includes: heat exchange aluminum tube 1, heat exchange aluminum sheet 2, iron heat accumulator 3, plexiglass plate 5, polystyrene plate insulation layer 7, temperature measuring thermocouple 12; in

[0015] The heat exchange aluminum sheet 2 is uniformly fixed along the outer circumference of the heat exchange aluminum tube 1 to form a whole; the upper part of the heat exchange aluminum tube 1 is a hot water inlet 8, and the lower part of the heat exchange aluminum tube 1 is a hot water outlet 9; the hot water inlet 8 passes through the The water pipe 15 is connected with the pumping constant temperature water bath 13, and high-temperature water is introduced, and the hot water outlet 9 flows out.

[0016] The heat exchange aluminum sheet 2 is placed in the iron heat accumulator 3, and the top and bottom of the iron heat accumulator 3 are closed by a plexiglass plate 5; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com