A surface assembly device

A technology for assembling equipment and curved surfaces, which is applied in the direction of mechanical equipment, workpiece clamping devices, and material gluing. It can solve the problems of glue opening, low lamination accuracy, and failure to stick to double-sided tape, so as to improve speed and improve assembly quality. The effect of increasing the efficiency and improving the fitting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

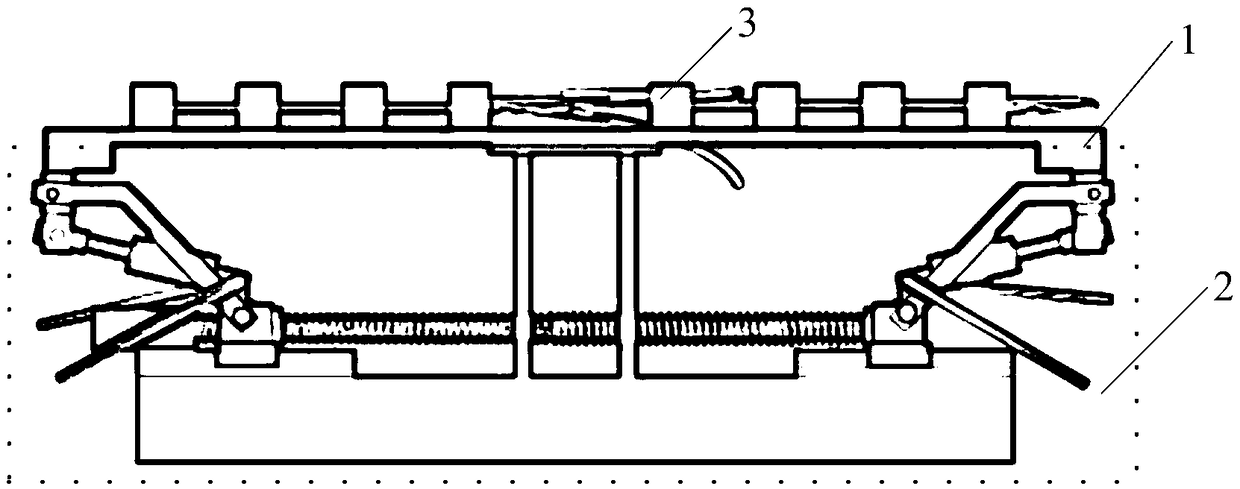

[0053] see figure 1 , an embodiment of the present invention provides a curved surface assembly equipment, including:

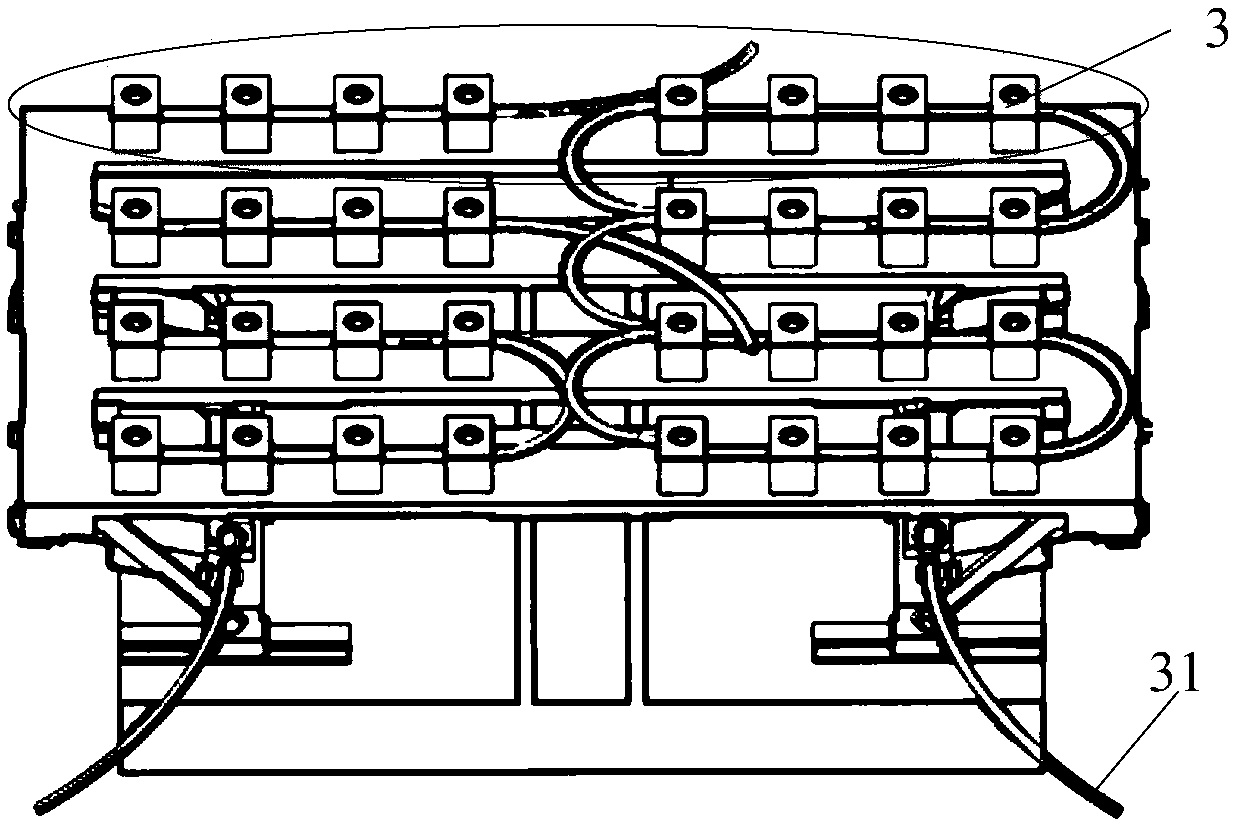

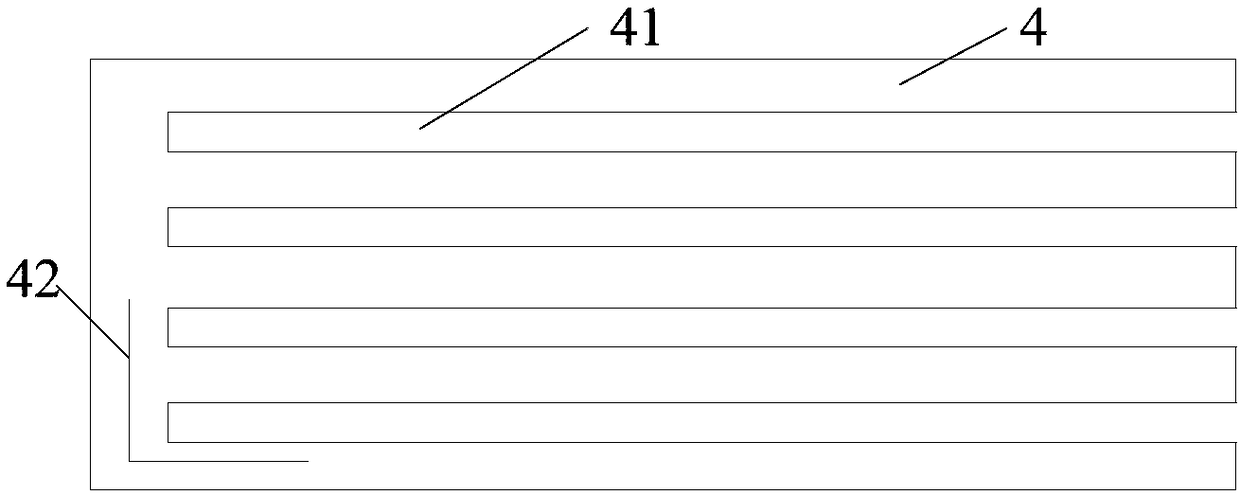

[0054] The bendable platform 1 and the curvature adjustment device 2 (the content in the dotted line box in the figure), the bendable platform 1 is provided with an adsorption unit 3, and the bendable platform 1 is installed on the curvature adjustment device 2;

[0055] The bendable platform 1 is configured to be bendable under the adjustment of the curvature adjusting device 2, so that the curvature of the bendable platform 2 reaches a specified curvature;

[0056] The adsorption unit 3 is configured to absorb the panel placed on the bendable platform 1 , so that the panel adheres to the bendable platform 1 .

[0057] The curvature of the surface object attached to the panel is also the specified curvature. For example, when the panel is a display panel, the curved object attached to the display panel is a curved backlight, and the curvature of the curved...

Embodiment 2

[0104] An embodiment of the present invention provides a method for attaching a panel to a curved object. The method can use any curved surface assembly device provided in the above embodiments to attach the panel to the curved object. see Figure 11 , the method includes:

[0105] Step 201: Use the curvature adjusting device to bend the bendable platform until the curvature of the bendable platform reaches a specified curvature and stop bending.

[0106] Specifically, each stretcher included in the curvature adjustment device is extended to push the support frame where each stretcher is located to rotate upwards to raise the two ends of the bendable platform, and at the same time, the motor drives the screw to rotate. The screw rod drives the two mechanical arms to move closer to each other, so that the bendable platform is bent until the curvature of the bendable platform reaches the specified curvature, and each retractor is stopped from continuing to extend and the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com