Wet electrostatic precipitator rear segment spraying program control optimized water saving method

A spraying water and post-stage technology, which is applied in the direction of electrical program control, program control in sequence/logic controller, electrostatic separation, etc., can solve the problem of excessive fresh industrial water consumption, increased wastewater treatment capacity, absorption tower removal Problems such as the fogger cannot be rinsed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

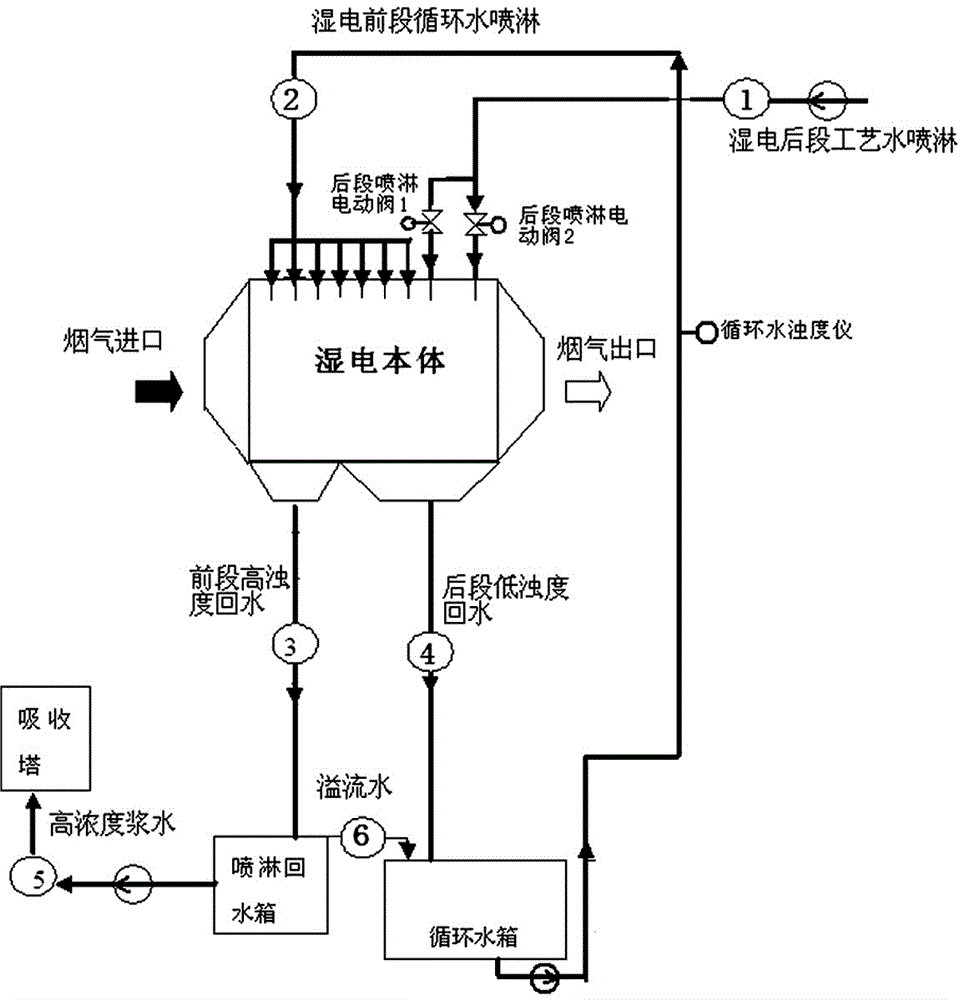

[0027] Embodiment: the water-saving method for optimizing the water-saving method of the post-spraying of the wet electricity according to the present invention, the water-saving method includes the following specific steps:

[0028] a. Judging the turbidity of the current wet power circulating water quality;

[0029] b. The value is within the normal range, automatically read the valve opening and closing time under different unit loads that have been set, and assign the value to the two rows of anode plate spray water valves in the rear section;

[0030] c. The spray water valves of the two rows of anode plates in the rear section are automatically opened or closed according to the assigned time;

[0031] d. Timing until the time is up, the corresponding valve will be automatically closed or opened;

[0032] e. Re-judge the current unit load every 30 minutes, re-assign the value again and automatically switch the valve according to the assignment;

[0033] f. According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com