In-situ self-assembly preparation method of ZnTPP (zinc tetraphenylporphyrin)/ZnO composite membrane nanomaterial

A technology of zinc tetraphenylporphyrin and tetraphenylporphyrin, applied in the field of in-situ self-assembly preparation of zinc tetraphenylporphyrin/zinc oxide composite film nanomaterials, to achieve improved quantum yield, high selectivity and High-efficiency photocatalysis, realizing the effect of visible light response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

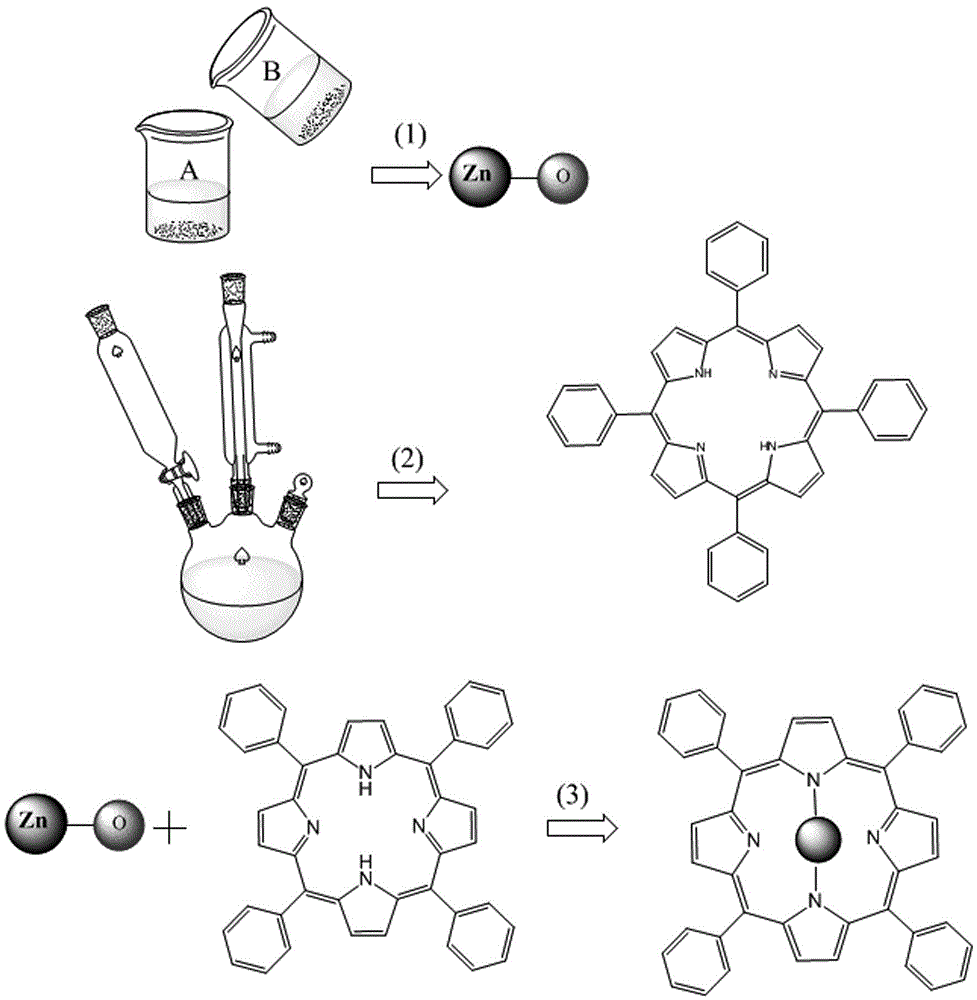

[0033] A preparation method for in-situ self-assembly of tetraphenylporphyrin zinc / zinc oxide composite film nanomaterials, the specific steps of which are:

[0034] (1) The ITO conductive glass is ultrasonically cleaned with cleaning agent, acetone, ethanol and deionized water respectively, with an interval of 10 minutes each time, and then dried in an oven at 80°C for later use;

[0035] (2) Weigh 0.5g of PVP and dissolve it in 30mL of water, then add 0.2g of glycine, 0.2g of zinc acetate and 0.2g of Na 2 SO 4 , and stirred evenly to form solution A, in addition, weighed 0.19g ammonium carbonate and dissolved in 20mL water to form solution B; then, under stirring conditions, slowly added solution B dropwise to solution A to form a mixed solution; then washed Put the clean ITO into the polytetrafluoroethylene reaction kettle, then pour the above mixed solution into the reaction kettle, then place the reaction kettle in a box-type resistance furnace, react at 180°C for 3 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com