Dust collector and fertilizer machine

A technology of dust removal device and fan, which is applied to mixers, transportation and packaging, mixer accessories, etc., can solve the problems of frequent disassembly of filter screens, and achieve the effect of not being easy to block, maintaining continuity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

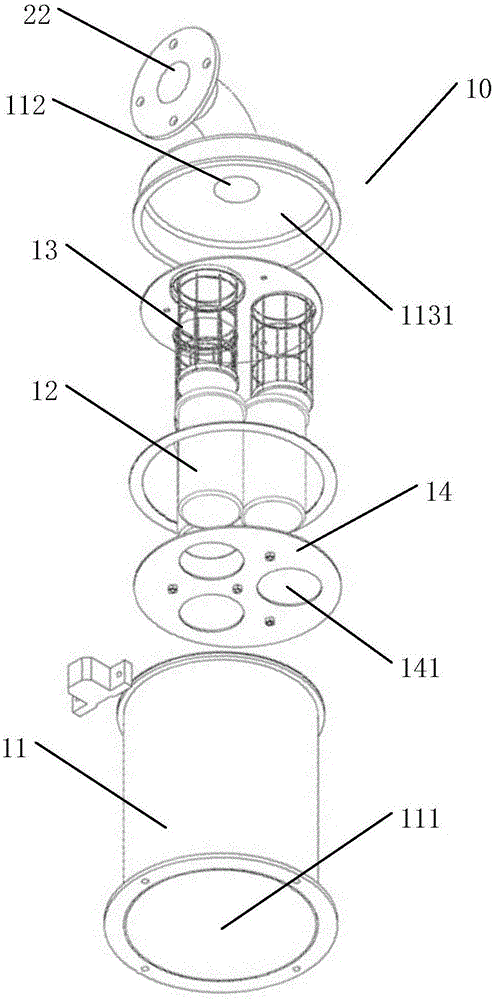

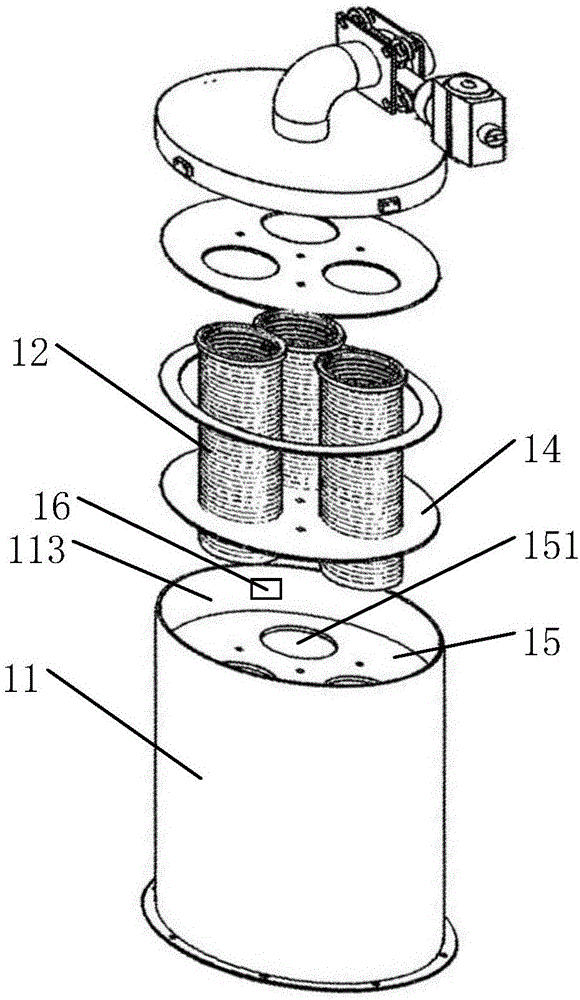

[0036] figure 2 It is a schematic diagram of the split structure of the dust removal device in the first embodiment of the present invention, image 3 It is a schematic diagram of the disassembled structure of another angle of the dust removal device in Embodiment 1 of the present invention, such as figure 2 with image 3 As shown, the dust removal device 10 provided by the present invention includes: a housing 11 , a filtering mechanism 12 and an elastic mechanism 13 .

[0037] The housing 11 is provided with a first nozzle 111, a second nozzle 112 and a filter cavity 113, and the filter cavity 113 is arranged between the first nozzle 111 and the second nozzle 112; One end of the elastic mechanism 13 is disposed inside the top wall 1131 of the filter chamber 113 , and the other end of the elastic mechanism 13 is disposed with the filter mechanism 12 , and the filter mechanism 12 is disposed in the filter chamber 113 . Elastic mechanism 13 can adopt spring.

[0038] Wher...

Embodiment 2

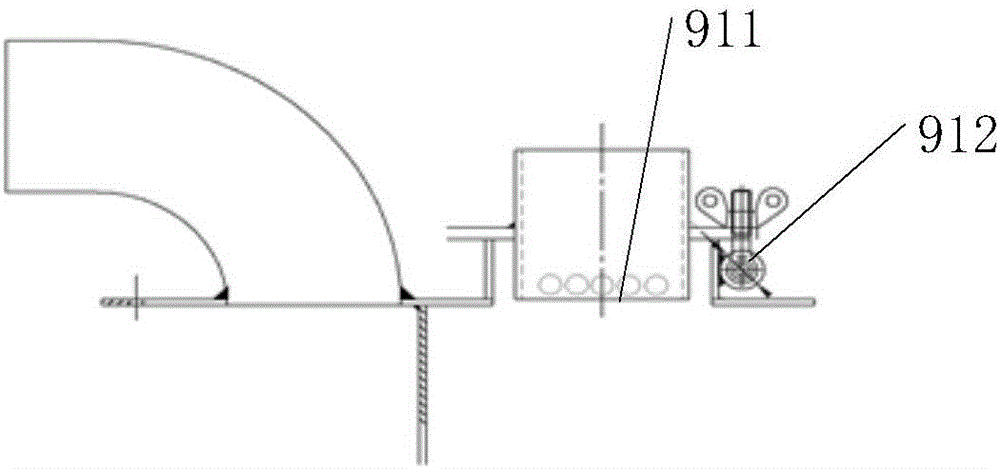

[0055] Figure 7 It is a partial structural schematic diagram of the fertilizer distributing machine of the second embodiment of the present invention, Figure 8 It is a schematic diagram of the connection structure between the storage bin and the dust removal device in Embodiment 2 of the present invention, as Figure 7 with Figure 8 As shown, the fertilizer dispensing machine provided by the present invention includes: a storage bin 21, a fan (not shown in the figure) and the dust removal device 10 described in Embodiment 1 of the present invention.

[0056] Wherein, the first nozzle 111 communicates with the storage bin 21 . The second nozzle 112 communicates with the butterfly valve 22, and the butterfly valve 22 communicates with the fan. The first nozzle 111 is fixedly mounted on the storage bin 21 through an easy-to-disassemble buckle mechanism, which is convenient for disassembly.

[0057] Furthermore, in the fertilizer distributing machine according to the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com