Amide oil agent continuous water removal device and its water removal process

An amide and oil technology, applied in the field of dehydration of chemical oil, can solve the problems of poor separation effect, cannot be used for continuous operation, cannot separate oil and water, etc., achieves less investment, realizes continuous production operation, and reduces staff work. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

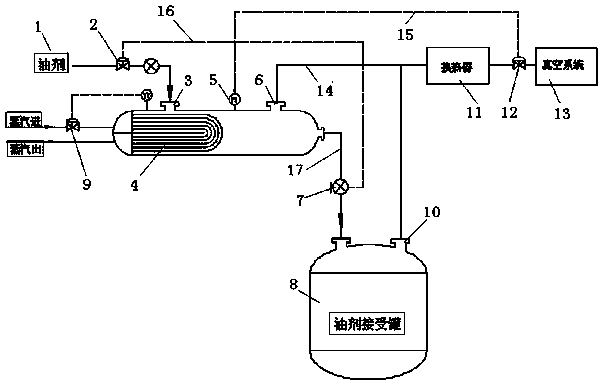

[0026] use as figure 1 The shown amide oil agent continuous water removal device has oil agent regulating valve 2, U-shaped tube heat exchanger 4, online moisture detector 7, Oil agent receiving tank 8.

[0027] The U-shaped tube heat exchanger 4 is connected with steam inlet and outlet pipelines for heat exchange, and the tube shell of the U-shaped tube heat exchanger 4 is also respectively connected with an oil agent inlet 3, a vacuum suction port 6, and a vacuum detector communicating with the inside thereof. 5. An oil agent discharge pipeline 17; a vacuum regulating valve 12 and a vacuum system 13 are installed and connected to the vacuum pipeline 14, and a heat exchanger 11 is connected to the vacuum pipeline 14. The oil agent receiving tank 8 has a vacuum outlet 10 connected to a vacuum pipeline 14 .

[0028] An oil agent control circuit 16 is connected between the online moisture detector 7 and the oil agent regulating valve 2, and when the online moisture detector 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com