Head joint dual-way joint for rapidly flushing inner wall of nasal feeding pipe

A technology for rapid flushing and feeding tube, applied in the field of medical devices, can solve the problems of shortening the service life of the feeding tube, difficult to clean, easy to breed bacteria, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

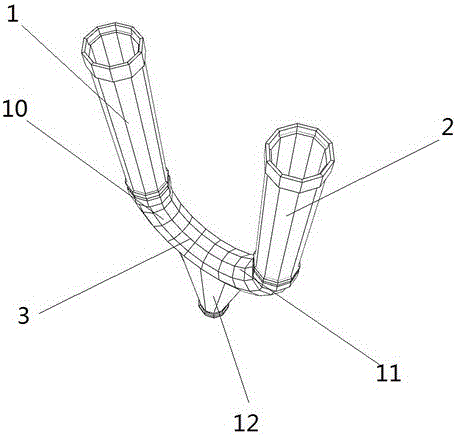

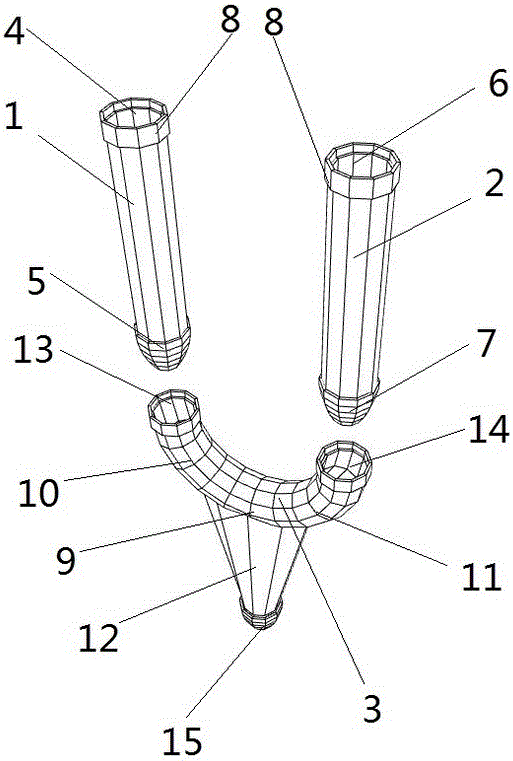

[0018] Embodiment 1 refers to figure 1 and figure 2 , this embodiment provides a two-way connector for quickly flushing the inner wall of a nasal feeding tube, including a nasal feeding tube 1, a flushing tube 2 and a three-way tube 3; one end of the nasal feeding tube 1 is the injection port 4 of the nasal feeding tube, and the other end is the nasal feeding tube Tube tee connection port 5; one end of the flushing pipe 2 is the flushing tube injection port 6, and the other end is the injection tube tee connection port 7; a syringe connector is fixedly installed at the injection port 4 of the nasal feeding tube and the injection port 6 of the flushing tube 8; The three-way pipeline 3 includes a first-way pipeline 10, a rear-way pipeline 11, and a liquid outlet pipeline 12 connected to each other at a connection point 9, and the first-way pipeline 10 includes a nasal feeding tube connected to the three-way connection port 5 of the nasal feeding tube Insertion joint 13 , the r...

Embodiment 2

[0019] Embodiment 2 refers to image 3 , this embodiment provides another two-way connector for quickly flushing the inner wall of the nasal feeding tube, the structure of which is roughly the same as that provided in Example 1, including a nasal feeding pipeline 1, a flushing pipeline 2 and a three-way pipeline 3; nasal feeding pipeline 1 One end of the tube is the injection port 4 of the nasal feeding tube, and the other end is the three-way connection port 5 of the nasal feeding tube; one end of the flushing pipe 2 is the injection port 6 of the flushing tube, and the other end is the three-way connection port 7 of the injection tube; it is located at the injection port 4 of the nasal feeding tube A syringe joint 8 is fixedly installed at the injection port 6 of the flushing tube; the three-way pipeline 3 includes a first road pipeline 10, a back road pipeline 11 and a liquid outlet pipeline 12 connected to each other at a connection point 9, and the first road pipeline 10 i...

Embodiment 3

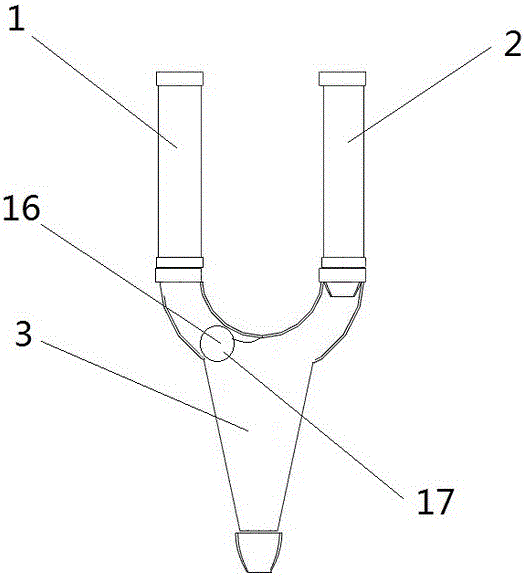

[0020] Example 3 This example provides another two-way connector for rapid flushing of the inner wall of the nasal feeding tube. One end of the pipeline 1 is the injection port 4 of the nasal feeding tube, and the other end is the three-way connection port 5 of the nasal feeding tube; one end of the flushing pipeline 2 is the injection port 6 of the irrigation tube, and the other end is the three-way connection port 7 of the injection tube; it is located at the injection port of the nasal feeding tube A syringe joint 8 is fixedly installed at the 4 places and the 6 places of the injection port of the flushing pipe; It includes a nasal feeding tube insertion joint 13 connected to the three-way connection port 5 of the nasal feeding tube, the posterior pipeline 11 includes a flushing tube insertion joint 14 connected to the three-way connection port of the flushing tube, and the liquid outlet pipeline 12 includes a liquid outlet joint 15. There is a spherical valve plate 16 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com