Start melting device and method for preparing high-purity metallic oxide by using cold crucible

A technology for starting melting and oxides, applied in crucible furnaces, lighting and heating equipment, furnaces, etc., and can solve problems such as high-purity oxide pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

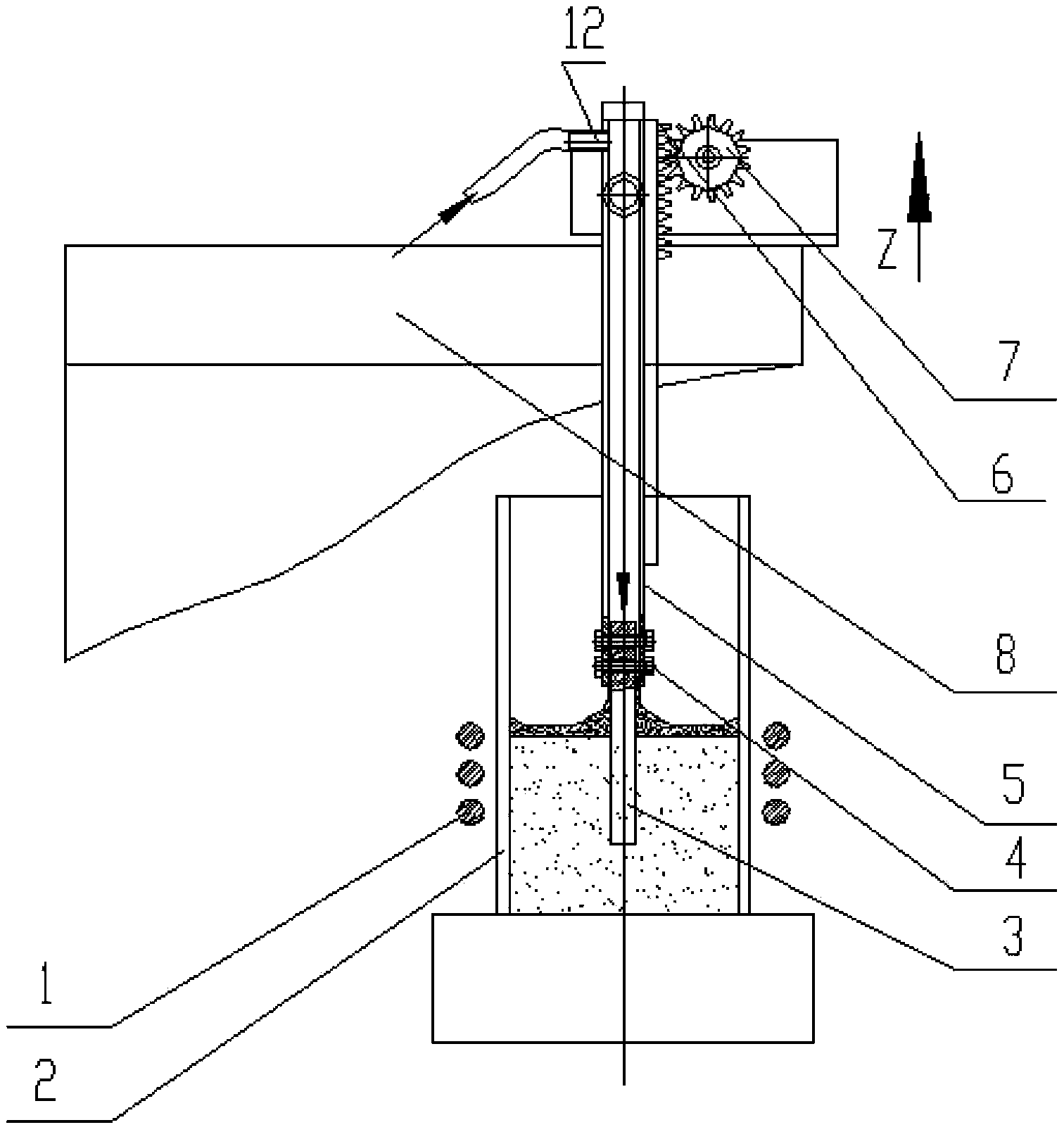

[0023] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

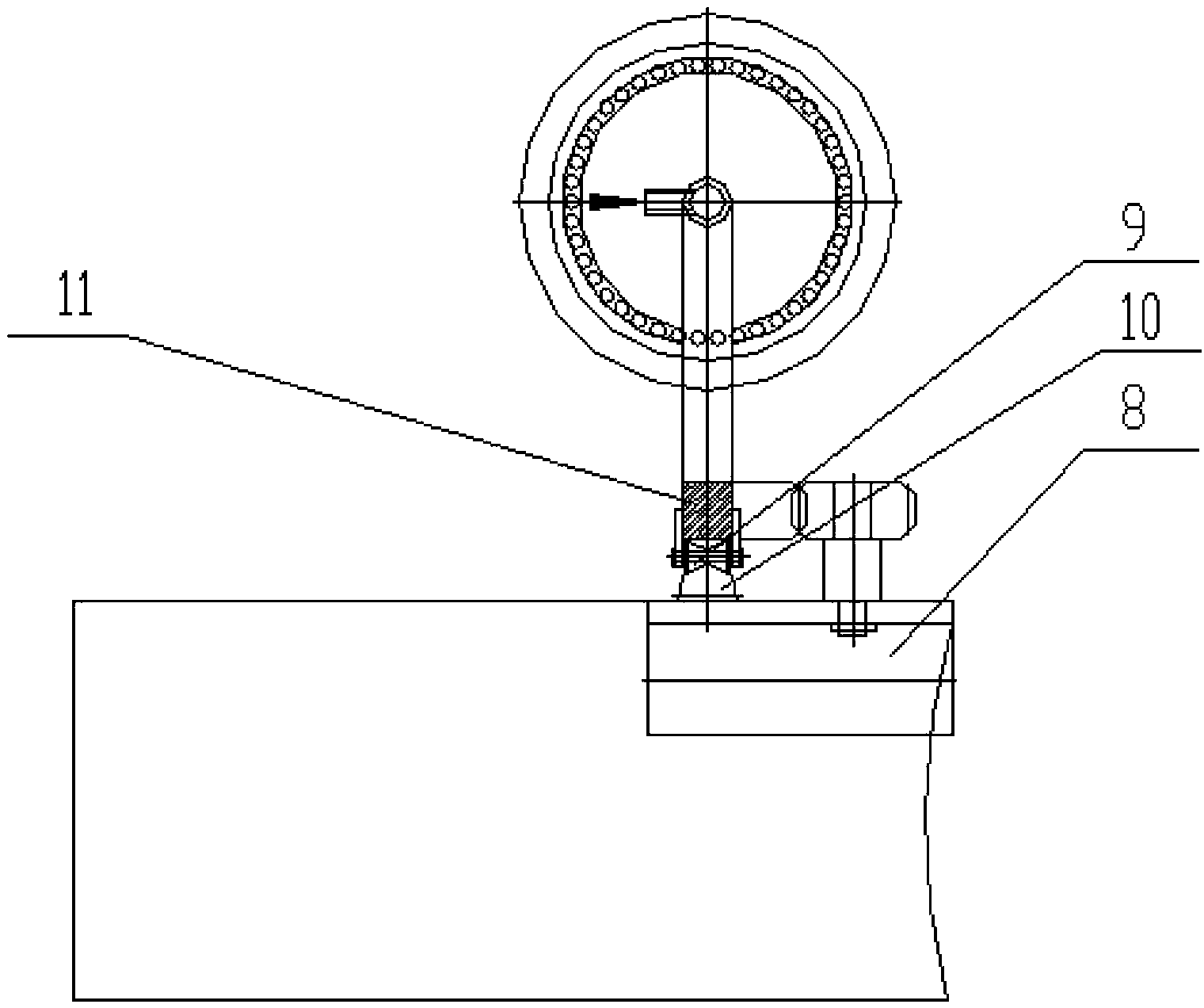

[0024] A start-up melting device for preparing high-purity metal oxides from a cold crucible, the device includes a crucible 2, an electromagnetic induction coil 1 arranged along the circumference of the crucible 2, a graphite rod 3, an alumina ceramic tube 5 and a lifting system, and a graphite rod 3 is set in the crucible 2, the high-purity graphite rod 3 is inserted into the high-purity alumina ceramic tube 5, and the two are connected by alumina ceramic bolts 4. The inner diameter of the alumina ceramic tube 5 is slightly larger than the outer diameter of the high-purity graphite rod 3, and there is a gap between the graphite rod 3 and the alumina ceramic tube 5, which can be 1-2mm. A protective gas (argon) is passed into the tube 5 . On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com