A kind of strawberry automatic destemming device

A strawberry and automatic technology, applied in the fields of application, food processing, food science, etc., can solve the problems of low efficiency, waste of labor, short storage time of strawberries, etc., and achieve the effects of improving processing efficiency, ensuring recycling, and preventing damage from falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

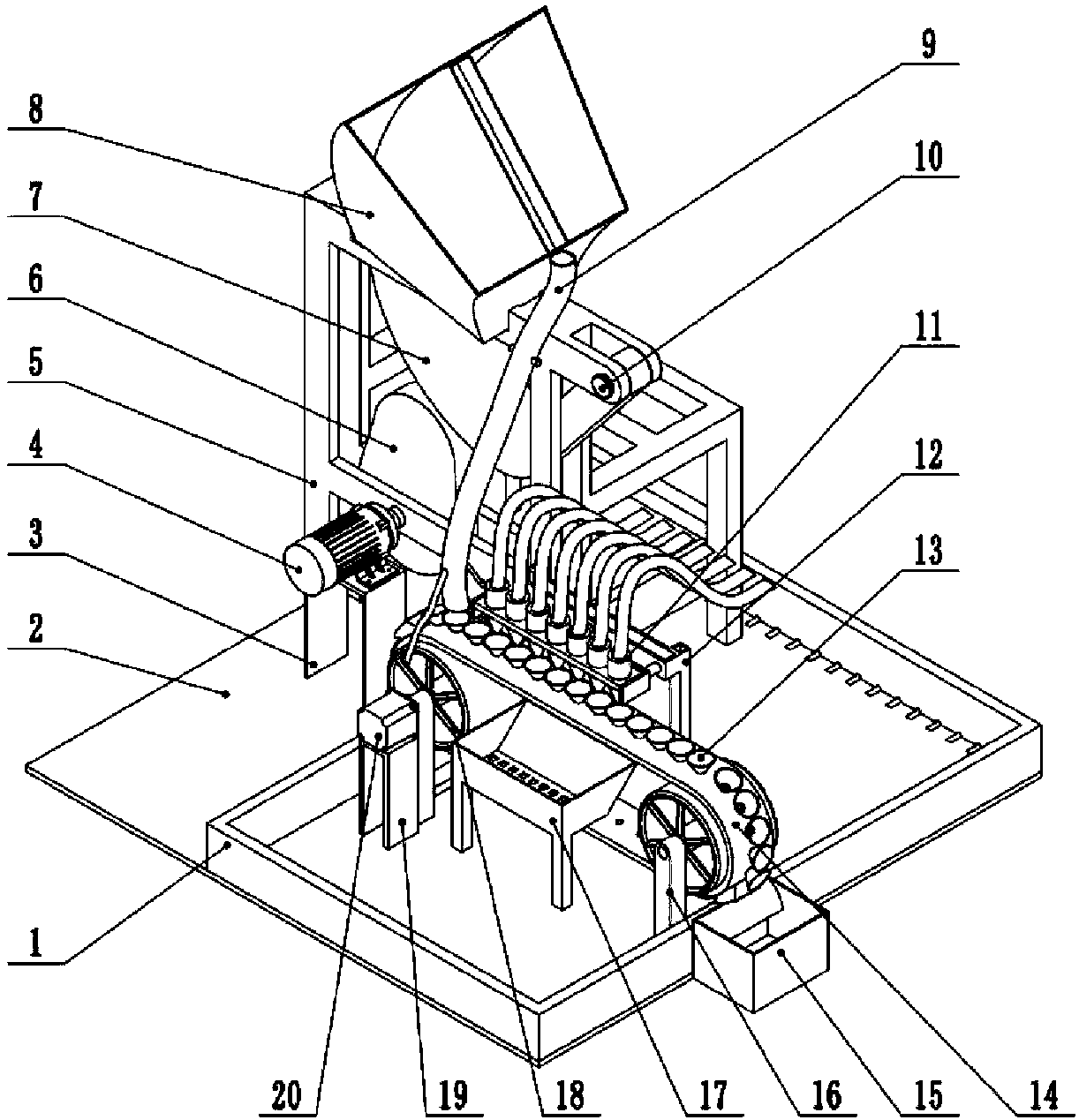

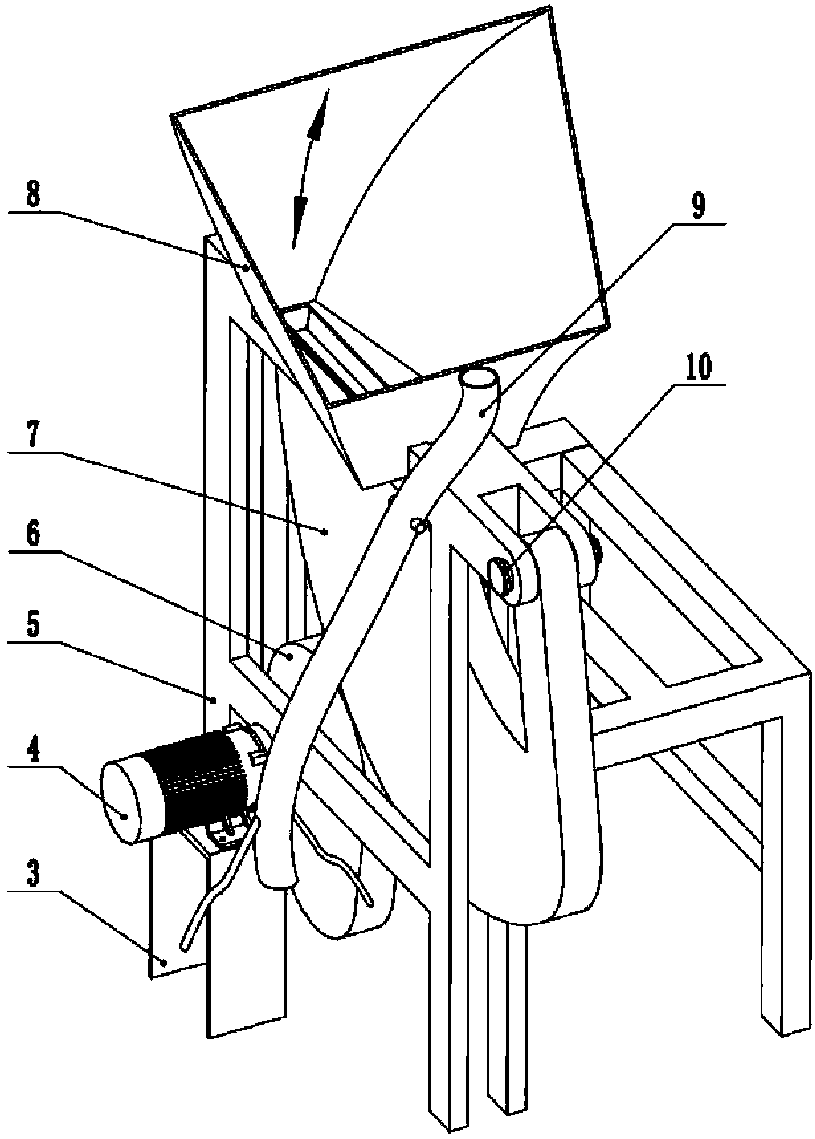

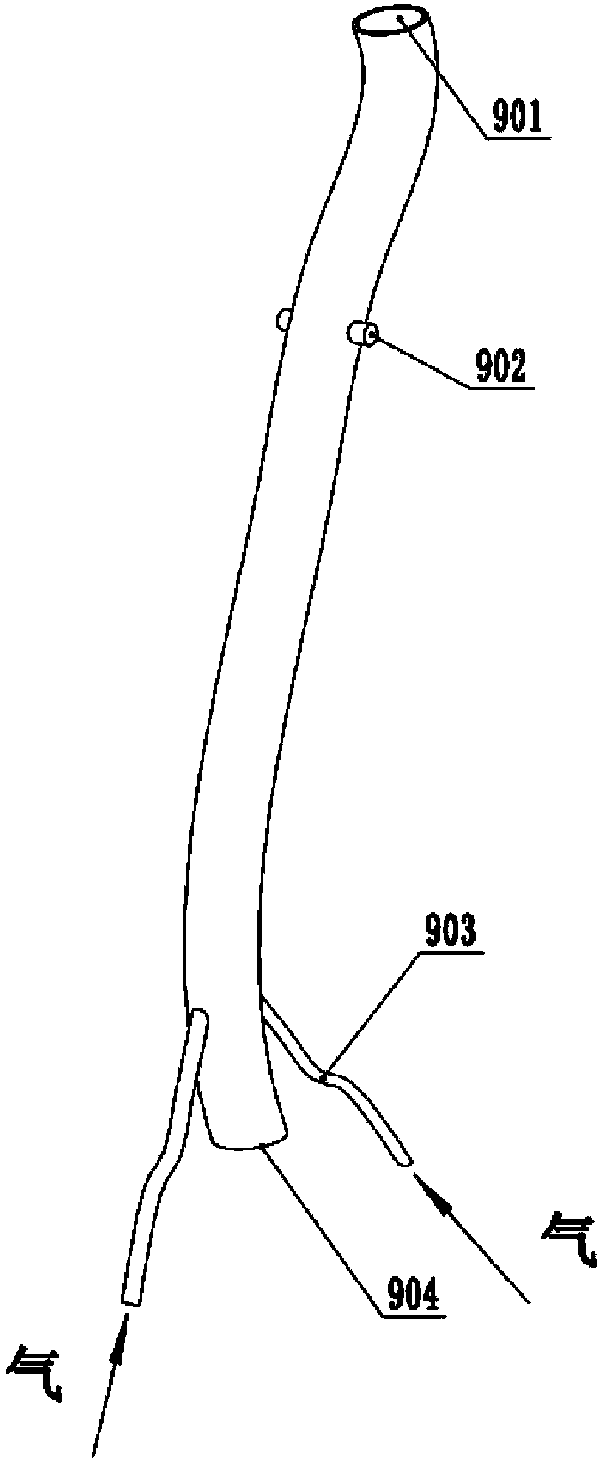

[0021] An automatic destemming device for strawberries is composed of a water tank 1, a base 2, an asynchronous motor support 3, an asynchronous motor 4, a strawberry feeding support 5, a cam 6, a strawberry supporting plate 7, a strawberry material box 8, a conveying pipe 9, and a pin shaft 10. Water cutting gun 11, cutting bracket 12, supporting bracket 13, belt 14, strawberry box 15, pulley bracket 16, strawberry pedicle box 17, pulley 18, stepping motor bracket 19 and stepping motor 20, on the base Water tank 1 is installed on 2, asynchronous motor bracket 3 is installed on base 2, asynchronous motor 4 is installed on asynchronous motor bracket 3, strawberry feeding bracket 5 is installed and fixed on base 2, and cam 6 is installed on the beam of strawberry feeding bracket 5 Above, the output shaft of the asynchronous motor 4 cooperates with the cam 6, the strawberry supporting plate 7 is connected with the strawberry feeding bracket 5 through the pin shaft 10, the strawber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com