Banana essence

A banana flavor and banana technology, applied in the field of banana flavor, can solve the problems of unrealistic flavor, decreased flavor quality of banana products, weak natural feeling, etc., and achieve the effect of rich aroma, excellent thermal stability, and enhanced aroma intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1, a kind of preparation method of natural banana essence, carries out following steps successively:

[0047] 1) Wash and peel the bananas:

[0048] Choose ripe and non-rotten bananas, wash them with running tap water, peel them, and take the banana pulp.

[0049] 2), anti-browning treatment:

[0050] 1000 g of the banana pulp obtained in step 1) is subjected to microwave enzyme inactivation, the microwave frequency is 2850±50 MHz, and the power is 20 W; the treatment is for 1 min, thereby inhibiting oxidative browning.

[0051] 3), beating:

[0052] The beater beats the banana pulp obtained in step 2) to a muddy material at a speed of 1600rpm / min to obtain banana pulp.

[0053] 4), enzymatic hydrolysis and aroma enhancement:

[0054] Add 0.1g pectinase, 1g cellulase, and 1g beta-glucosidase to the banana pulp obtained in step 3) as an enzyme preparation, and stir and react at 45°C for 90min at a stirring speed of 160rpm / min; After banana pulp.

[0055]...

Embodiment 2

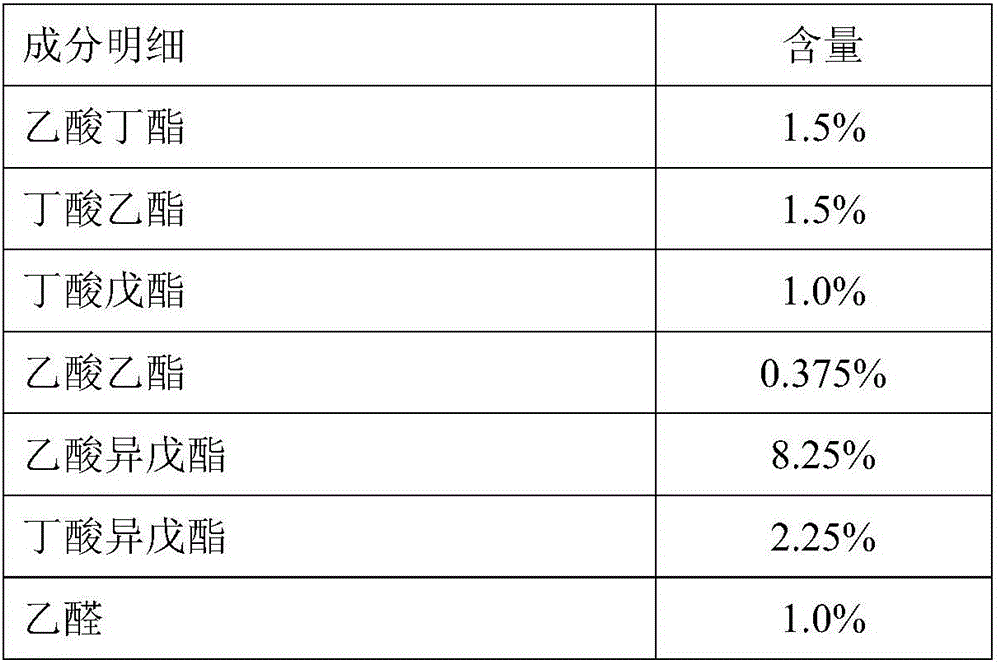

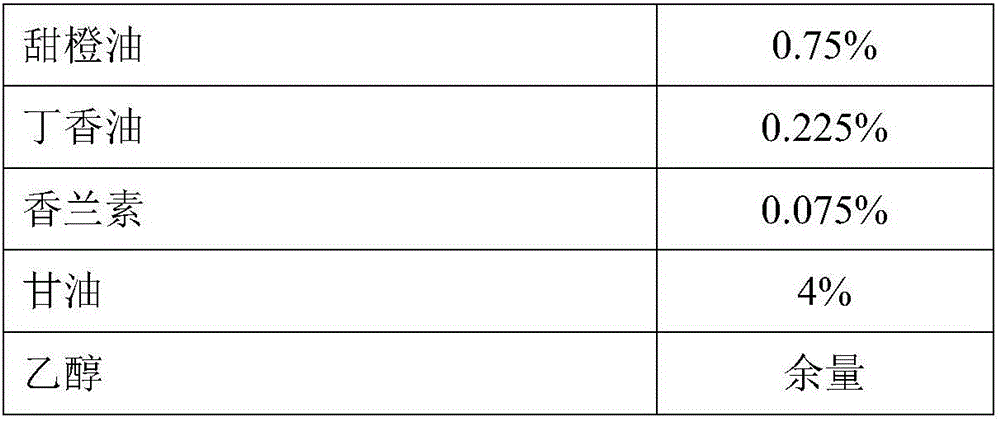

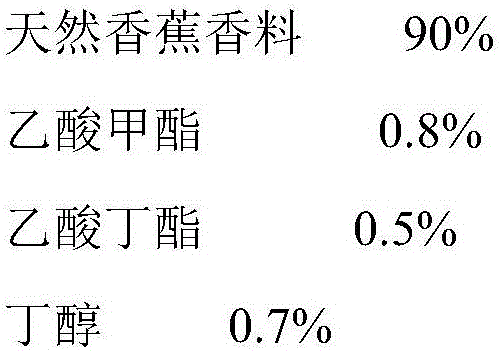

[0063] Embodiment 2, the formula of producing 100Kg banana essence is as shown in table 3:

[0064] table 3

[0065]

[0066]

[0067] The production process is as follows: add the ingredients described in Table 3 into the blending tank at normal temperature (10-30° C.), and stir in a sealed state until uniformly mixed; after sampling and testing pass, it is packaged and put into storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com