Preparation method of red bean drink

A technology of red bean beverage and red bean, which is applied to the functions of food ingredients, food ingredients as taste improvers, food science, etc., can solve the problems of cumbersome process steps, high process cost, and low value, so as to prevent cell aging, The effect of stable and uniform state and restoration of vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

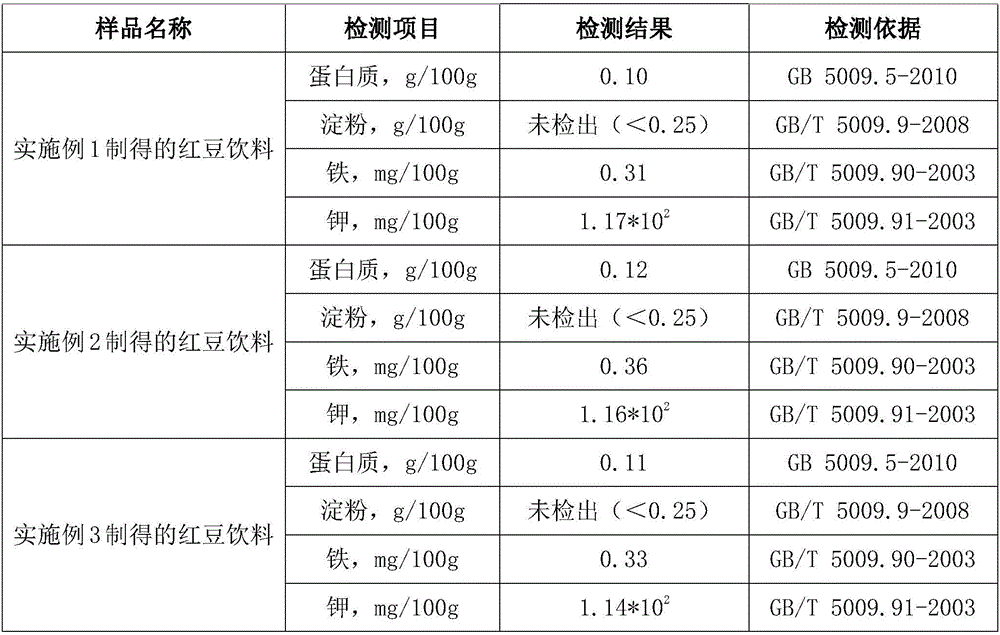

Examples

Embodiment 1

[0025] A kind of preparation method of red bean beverage, adopt following operation steps:

[0026] (1) Mix the selected and cleaned red beans with purified water in a weight ratio of 1:4, heat, and cook at 100°C for 70 minutes;

[0027] (2) Use a horizontal spiral centrifuge to separate and filter the red bean to obtain red bean cooking water, cool the red bean cooking water with a tubular heat exchanger, lower the temperature to 26°C, and set aside;

[0028] (3) The red bean cooking water cooled in step (2) is filtered through a 0.5 μm bag filter for the first time to obtain a filtrate for subsequent use;

[0029] (4) The primary filtrate of step (3) is continued to be filtered for the second time with a PVDF membrane with a molecular cut-off of 40,000 Daltons, and the concentrated juice is drained to obtain filtered clear juice A for subsequent use;

[0030] (5) filter clear juice A in step (4) and use a nanofiltration membrane with a molecular cutoff of 2000 Daltons to fi...

Embodiment 2

[0033] A kind of preparation method of red bean beverage, adopt following operation steps:

[0034] (1) Mix the selected and cleaned red beans with purified water in a weight ratio of 1:3, heat, and cook at 98°C for 75 minutes;

[0035] (2) Use a horizontal screw centrifuge to separate and filter the red bean to obtain red bean cooking water, cool the red bean cooking water with a tubular heat exchanger, lower the temperature to 25°C, and set aside;

[0036] (3) The red bean cooking water cooled in step (2) is filtered through a 0.5 μm bag filter for the first time to obtain a filtrate for subsequent use;

[0037] (4) The primary filtrate of step (3) is continued to be filtered for the second time with a PVDF membrane with a molecular cut-off of 40,000 Daltons, and the concentrated juice is drained to obtain filtered clear juice A for subsequent use;

[0038] (5) filter clear juice A in step (4) and use a nanofiltration membrane with a molecular cutoff of 2000 Daltons to filt...

Embodiment 3

[0041] A kind of preparation method of red bean beverage, adopt following operation steps:

[0042] (1) Mix the selected and cleaned red beans with purified water in a weight ratio of 1:5, heat, and cook at 100°C for 80 minutes;

[0043] (2) Separating and filtering red beans with a horizontal screw centrifuge to obtain red bean cooking water, cooling the red bean cooking water with a tubular heat exchanger, lowering the temperature to 30°C, and setting aside;

[0044] (3) The red bean cooking water cooled in step (2) is filtered through a 0.5 μm bag filter for the first time to obtain a filtrate for subsequent use;

[0045] (4) The primary filtrate of step (3) is continued to be filtered for the second time with a PVDF membrane with a molecular cut-off of 40,000 Daltons, and the concentrated juice is drained to obtain filtered clear juice A for subsequent use;

[0046] (5) filter clear juice A in step (4) and use a nanofiltration membrane with a molecular cutoff of 2000 Dalt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com