Compound linear guide having a fastening means

A technology of fixing device and guiding element, applied in the field of conveying system, can solve the problems of expensive, difficult to manufacture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

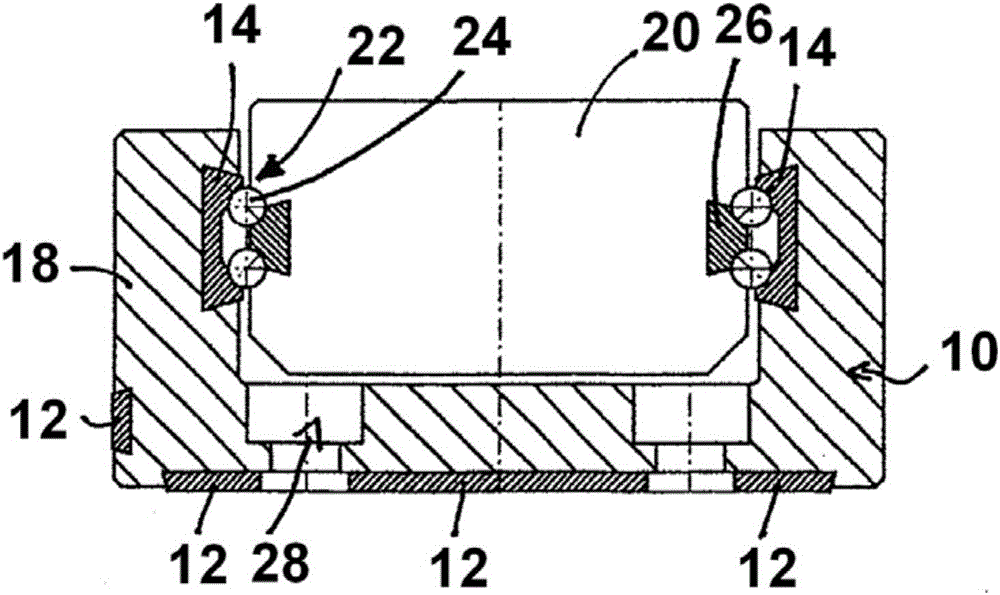

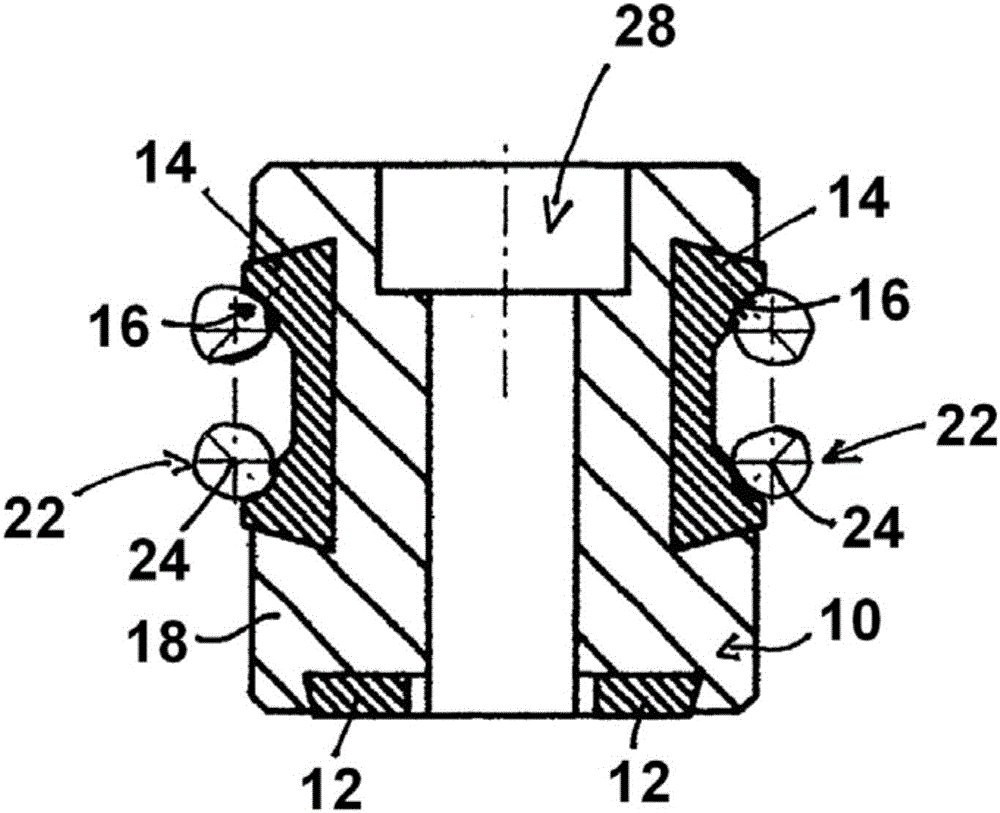

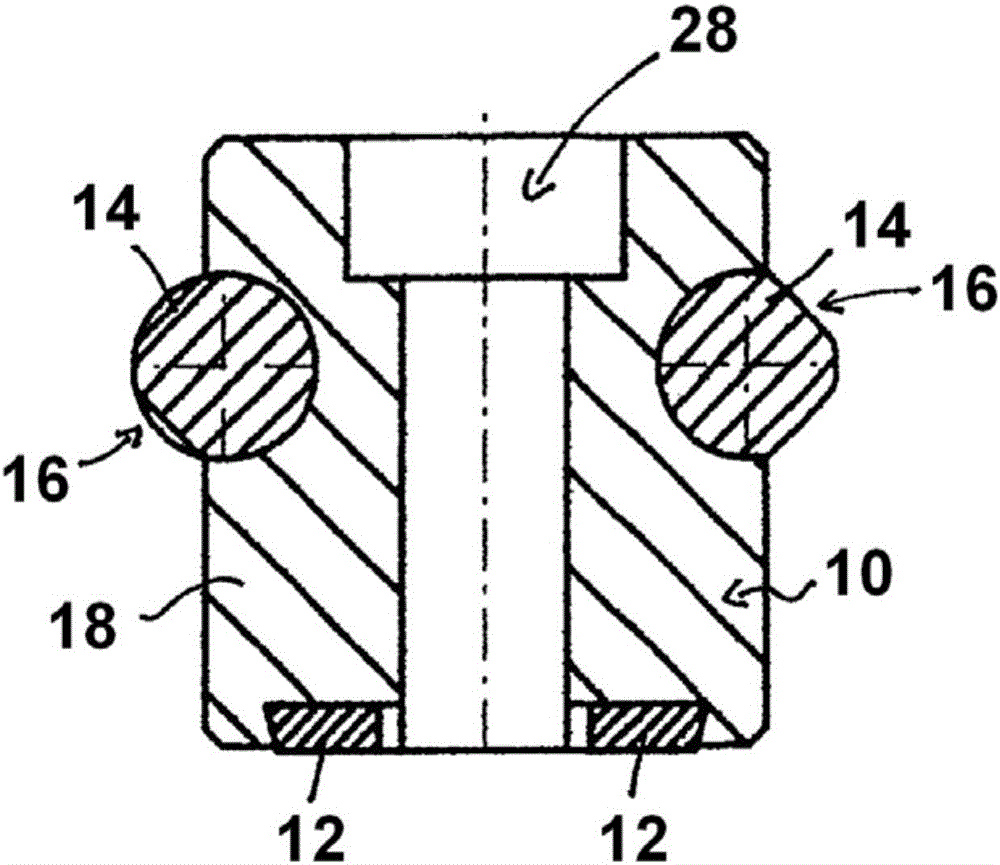

[0032] Figure 1 to Figure 4 Different embodiments of the guide rail 10 are shown, which are equipped with fixing means 12 for fixing the guide rail 10 to magnetic clamping means, not shown. Furthermore, each guide rail 10 is equipped with two guide elements 14 each having a guide surface 16 . Each fixing device 12 and each guide element 14 are attached to a non-magnetic light metal base 18 .

[0033] figure 1 An embodiment is shown in which the guide rail 10 has a U-shape and is partially engaged around the slider 20 from the outside. The slide 20 on which the object to be transported is arranged is linearly displaceably supported at the guide rail 10 by a bearing 22 . The bearing 22 comprises a plurality of roller elements 24 which are arranged between the rail-side guide element 14 and the slide-side guide part 26 and are in contact with the guide surface 16 . The guide element 14 , the guide part 26 and the fastening device 12 are inserted into trapezoidal grooves form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com