Roller type transport

A technology of conveyor and roller type, which is applied in the direction of transportation and packaging, roller table, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

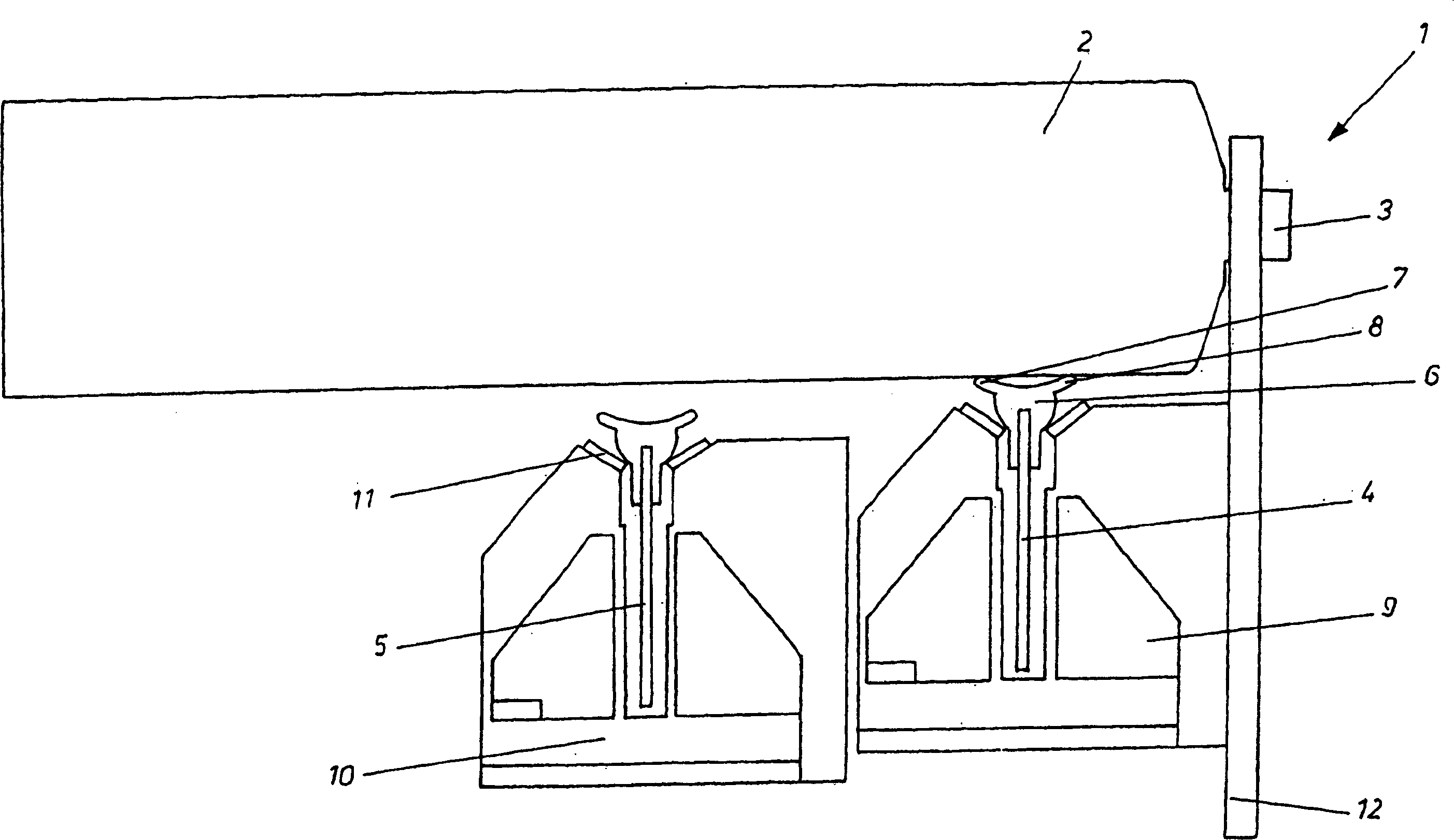

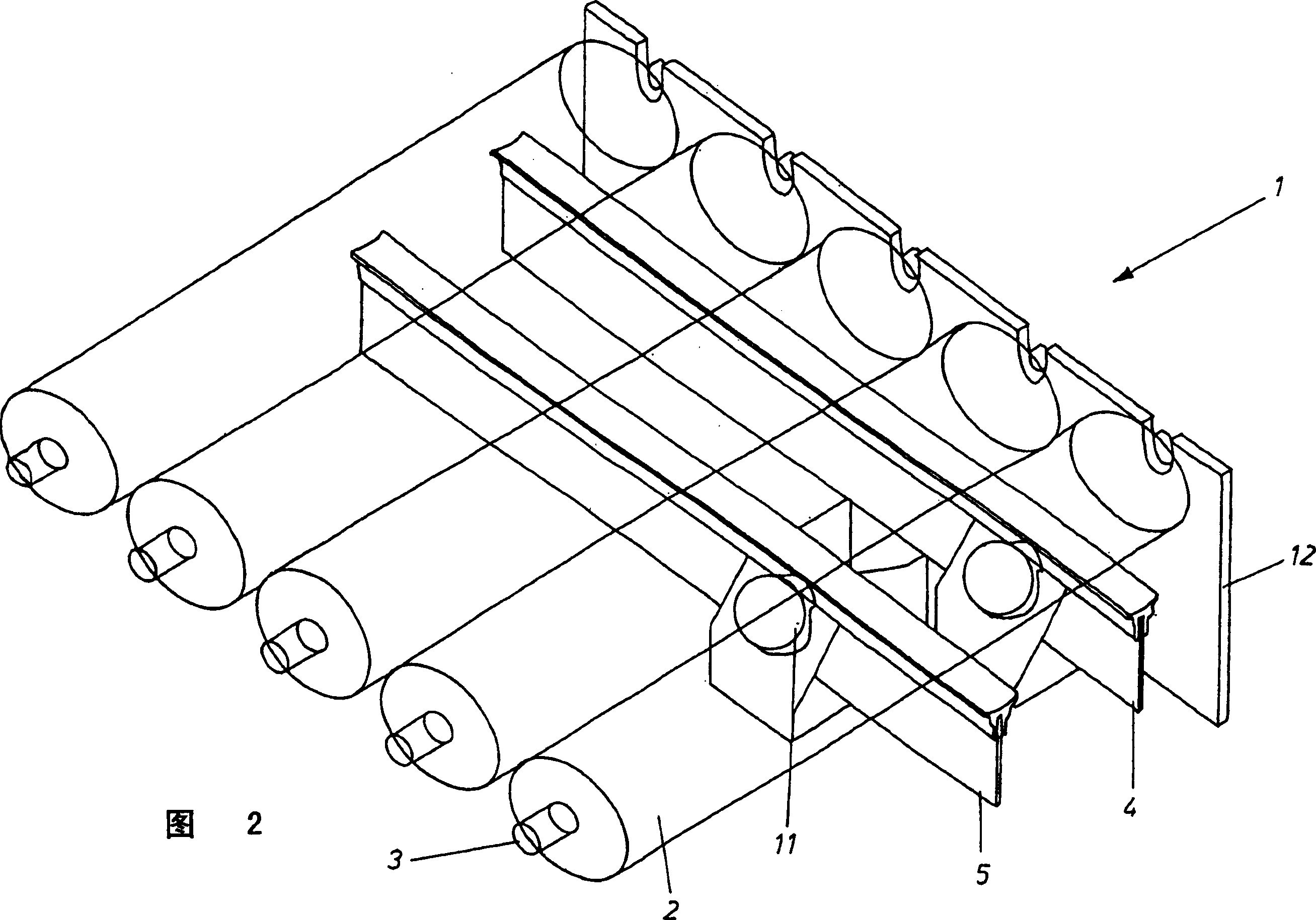

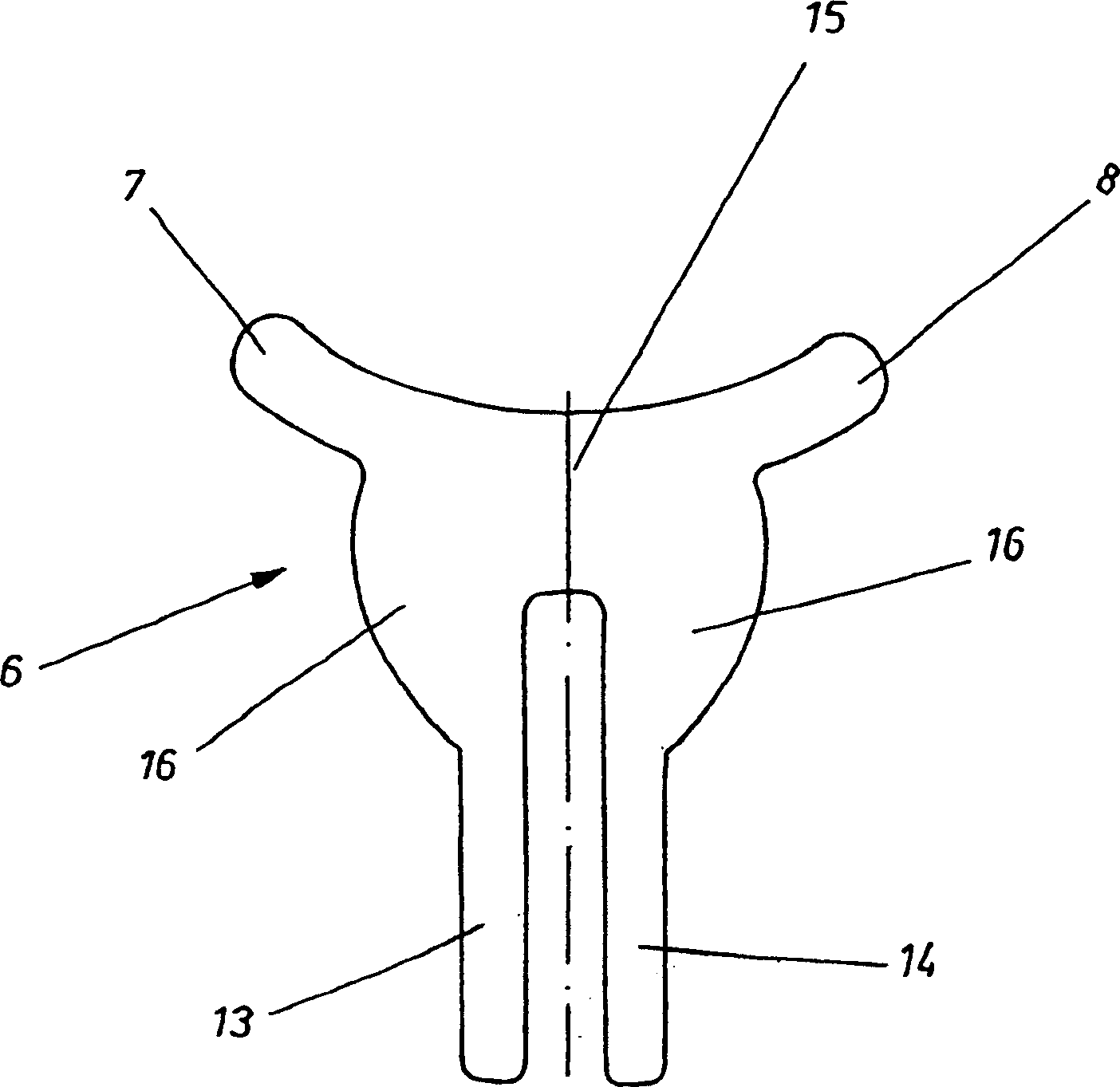

[0019] figure 1 A cross section through a roller conveyor according to the invention is shown. The roller 2 with the axis 3 is fixed in a side frame 12 . A plurality of such rollers 2 arranged one behind the other form the main part of the roller conveyor designated as a whole by 1 . The roller conveyor is driven by a vertically arranged belt 4 whose cross section is substantially elongated or rectangular. The same revolving belt is indicated by 5 in its return segment. This return section of the belt 5 is run lower than the forward drive section of the belt 4 so that only the upper area of the belt 4 is in contact with the roller 2 upwards. For this purpose the belt 4 is fastened in a bearing seat 9, or the return belt 5 is fixed in a bearing seat 10, or they are guided and driven by the drive element 11. The belt 4 has a profiled element 6 on its upper edge, which has two pre-bent or upwardly bent portions 7 and 8, which form a two-point bearing on the roller 2 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com