Oscillating slide machine

A slide valve and mechanical technology, applied in the field of swing slide valve machinery, can solve problems such as pulsation, limited bending angle, and stability of swing webs, and achieve the goals of reducing pulsation and cavitation, increasing maximum eccentricity, and improving operating performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

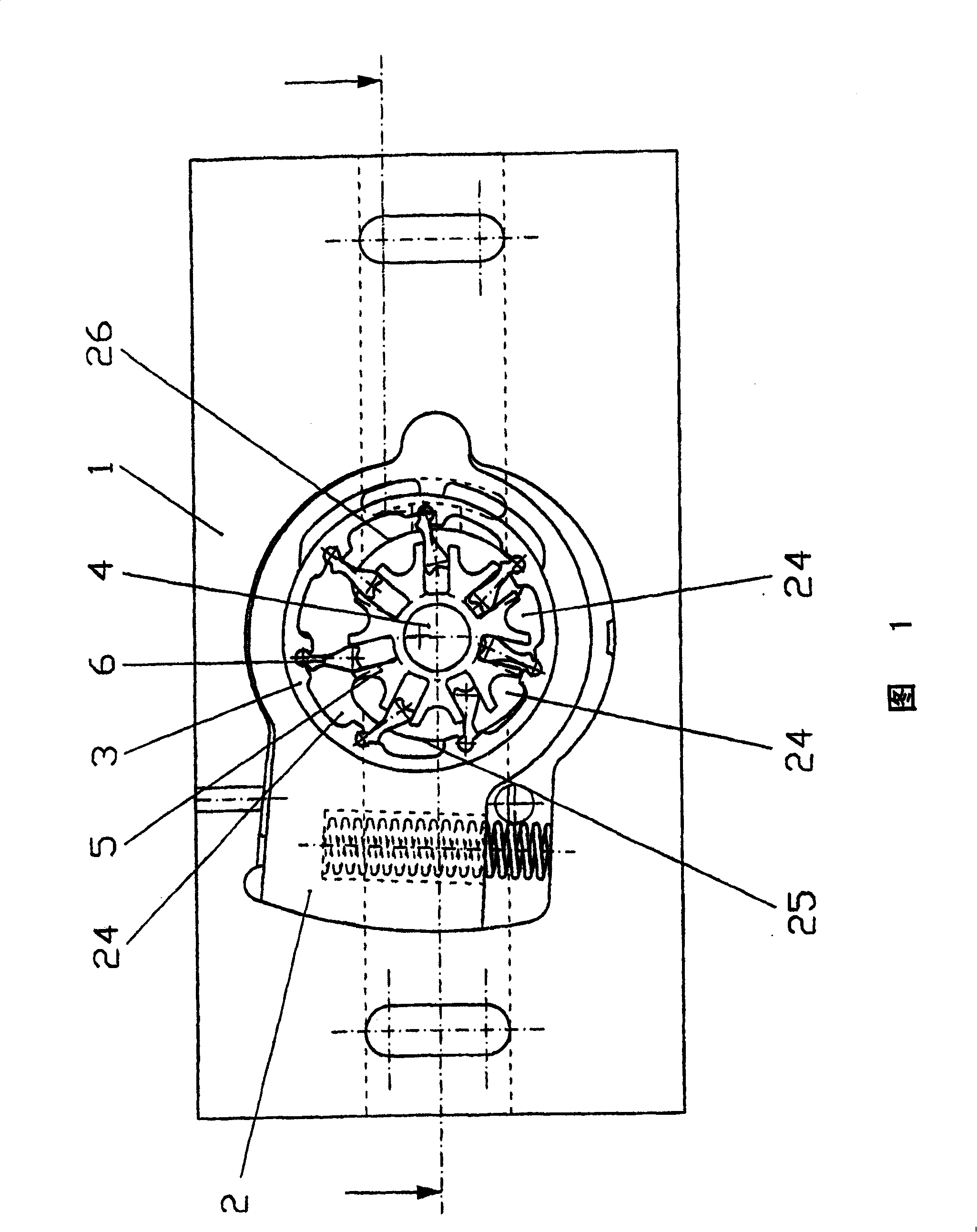

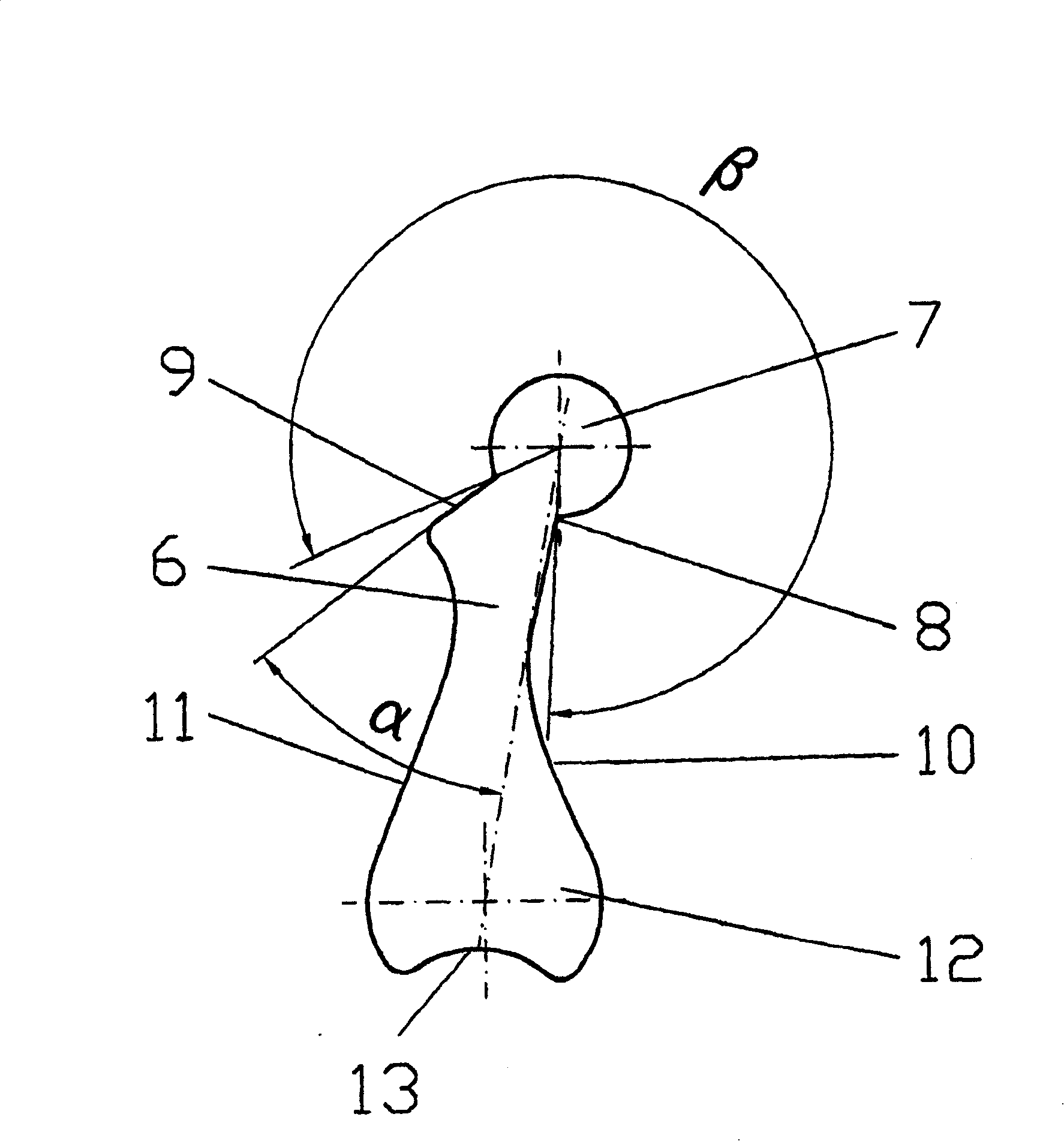

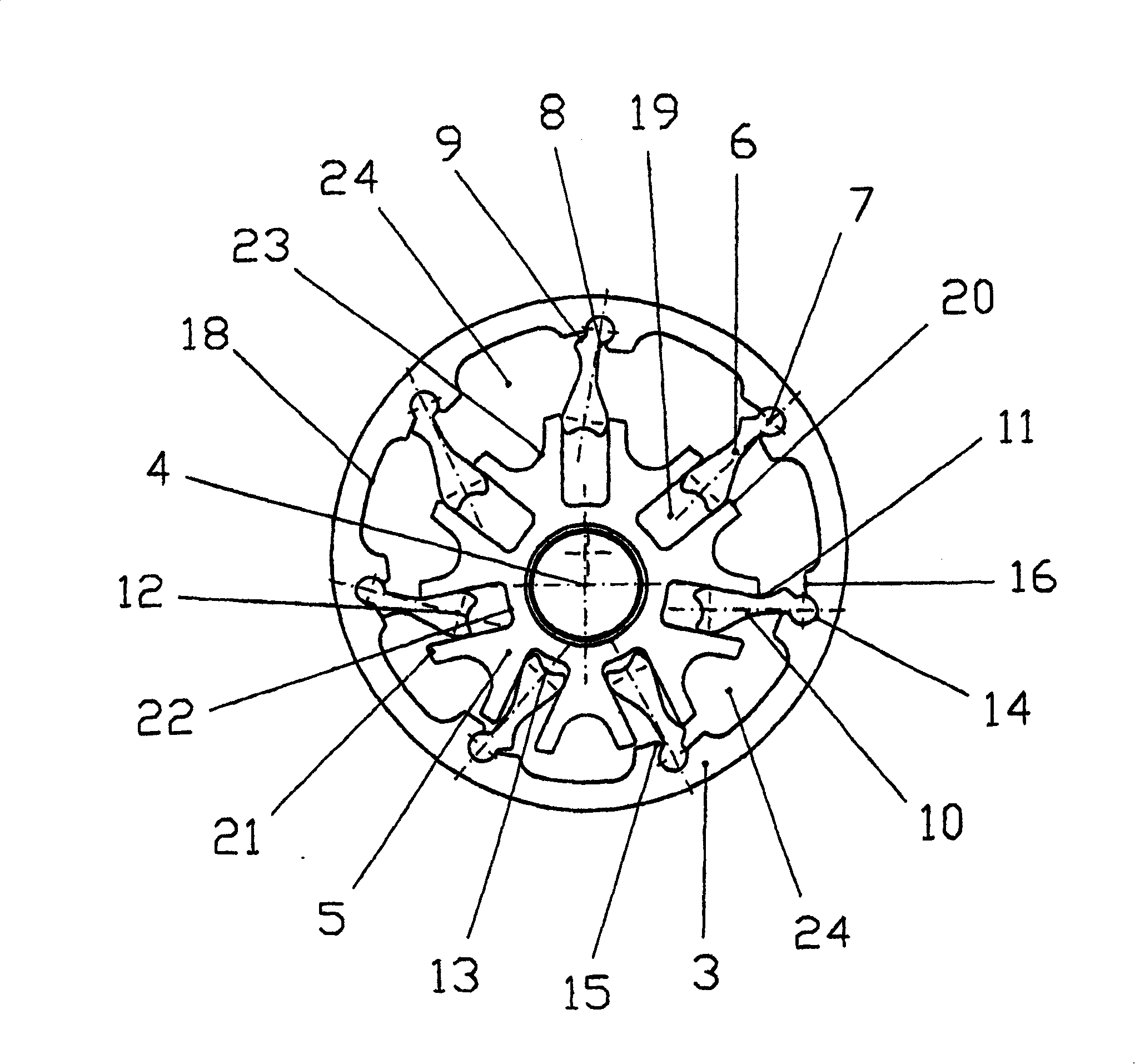

[0036] FIG. 1 shows a possible embodiment of the oscillating slide valve mechanism according to the invention in a sectional side view. A control slide valve 2 is arranged in the housing 1 . The outer runner 3 of a runner set is rotatably arranged in the control slide.

[0037] This runner set consists of an inner runner 5 arranged on a drive shaft 4 , which is connected to the outer runner 3 via seven oscillating webs 6 for rotational movement.

[0038] The individual pump chamber volumes of the pump chambers 24 formed between the adjacent swinging webs 6, the outer runner 3 and the inner runner 5 successively move to a maximum volume when the drive shaft 4 rotates one revolution and then Move to a minimal volume (or vice versa).

[0039] With the increased volume of the pump chamber 24 , the medium to be conveyed is sucked into the pump chamber 24 through suction openings 25 provided in the housing 1 and / or in the housing cover.

[0040] Offset by 180° in the direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com