Vehicle tyres

A technology for pneumatic tires and vehicles, applied to the reinforcement layer of pneumatic tires, heavy-duty tires, heavy-duty vehicles, etc., can solve the problems of durability and adverse effects of wear, and achieve the effect of favorable wear performance, simple method, and good force transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

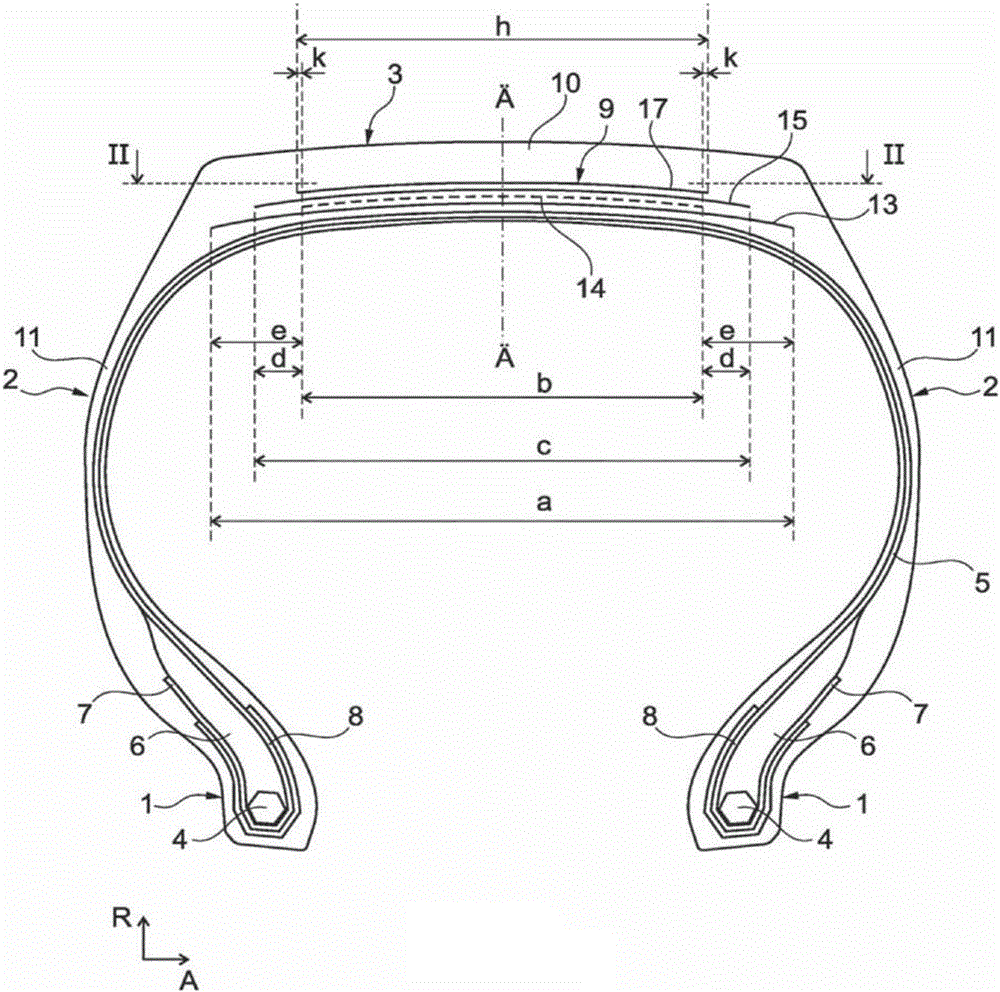

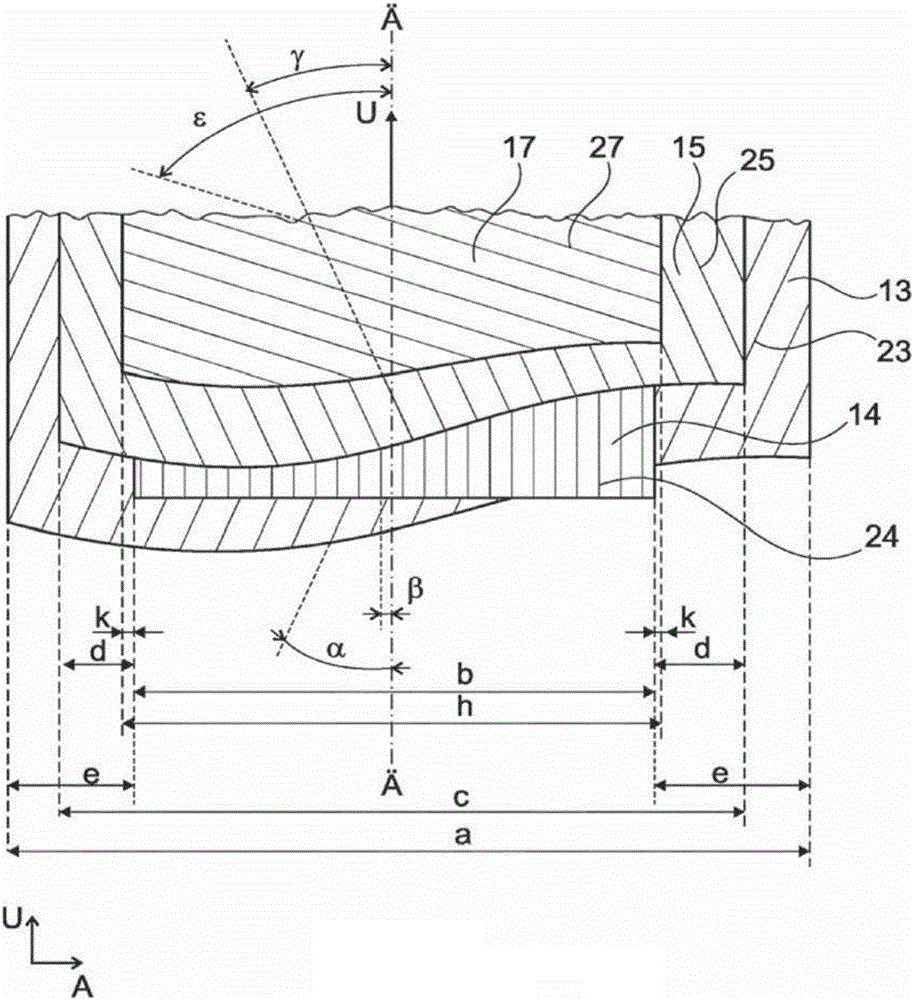

[0021] figure 1 and figure 2 A commercial vehicle pneumatic tire of radial construction is shown having two side walls 2 extending in the radial direction R of the vehicle pneumatic tire and a crown region (top region) formed axially therebetween 3. At the end of their extension directed inwards in the radial direction, the side walls are each formed with a bead region 1 in which a stretch-resistant, zugfester in the circumferential direction U is formed. A bead core 4 of known type extending on the circumference of the tyre. The bead core 4 is formed in a known manner from a coil of wire embedded in rubber extending in the circumferential direction U of the vehicle pneumatic tire. On the bead core 4 , a horn (core shoe) 6 with a triangular cross-section is formed in a conventional manner from hard rubber material. The vehicle pneumatic tire is formed to have a carcass 5 passing outwardly in the radial direction R of the vehicle pneumatic tire from the bead core 4 formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com