A construction method for a large-area floor

A construction method and large-area technology, applied in the direction of floors, buildings, building components, etc., can solve problems such as the inability to transmit force, the inability of reinforced frames to connect with each other, and the easy damage to the floor, so as to facilitate the smoothing operation and improve the The effect of force transmission and damage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0046] A construction method of a large-area floor disclosed by the invention, the construction method comprises the following steps:

[0047] Step S1: Level the ground, then lay the slag cushion and compact it.

[0048] Since the space of the construction site is large enough, the road roller can be driven in directly to compact the slag cushion, saving manpower.

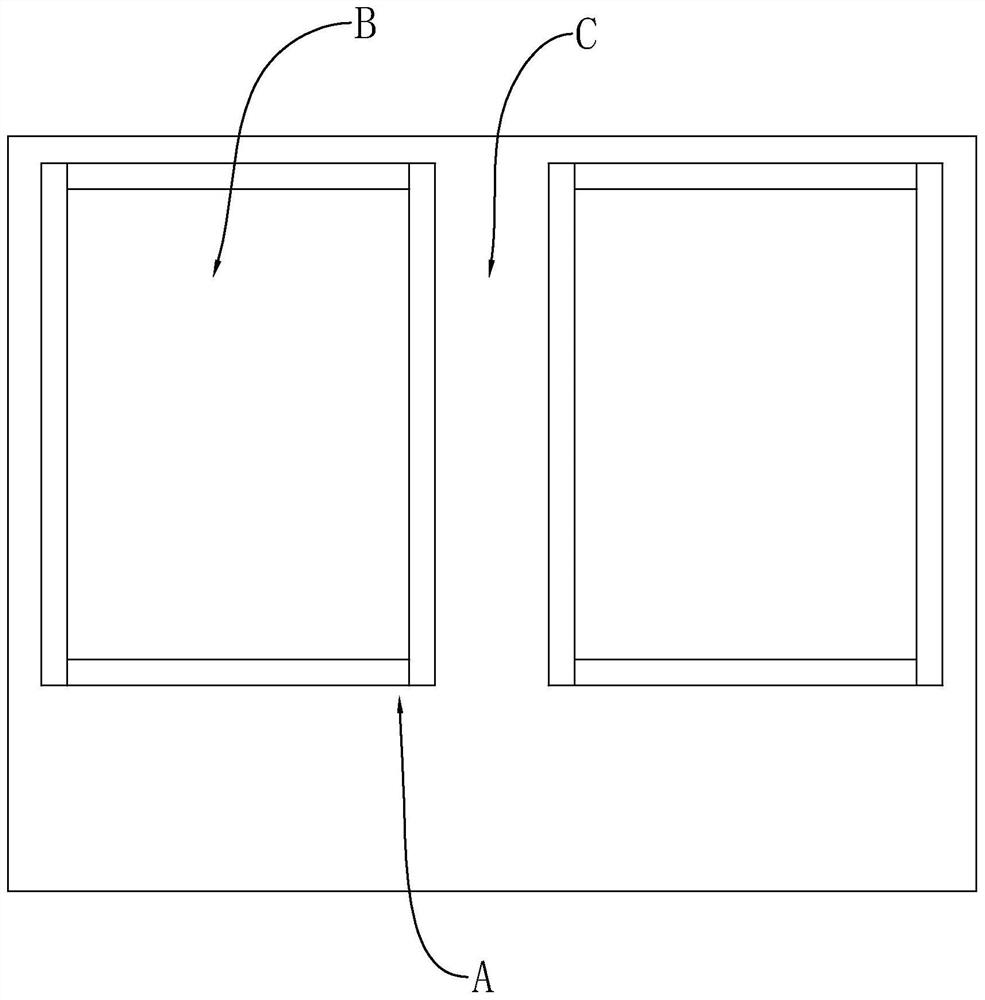

[0049] Step S2: see figure 1, to divide several independent main construction areas B, and there is an aisle C between adjacent main construction areas B.

[0050] The shapes of each main construction area B are rectangular with the same shape in the top view, and each main construction area B is arranged side by side at equal distances, and one end of the main construction area B in the length direction faces the exit side of the construction site.

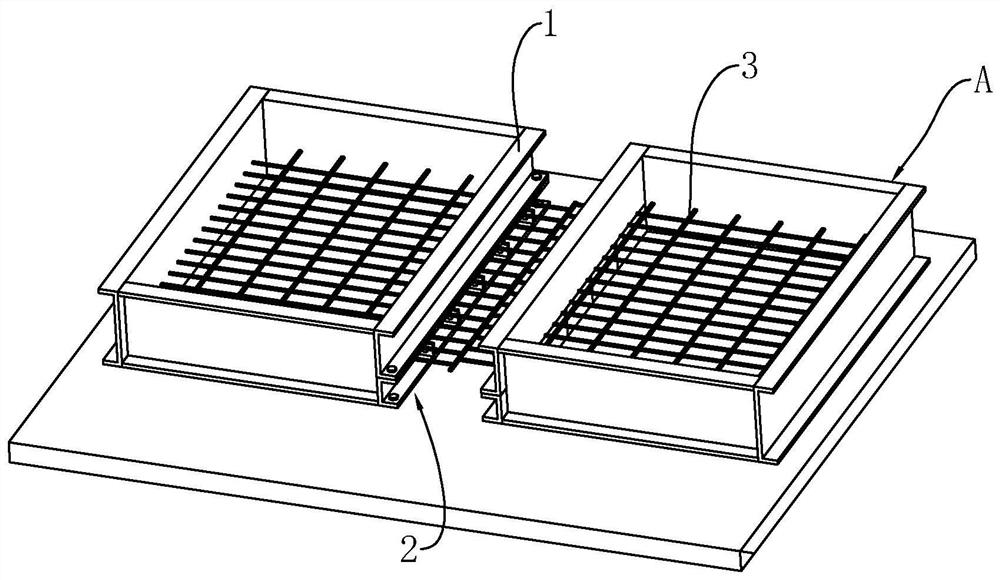

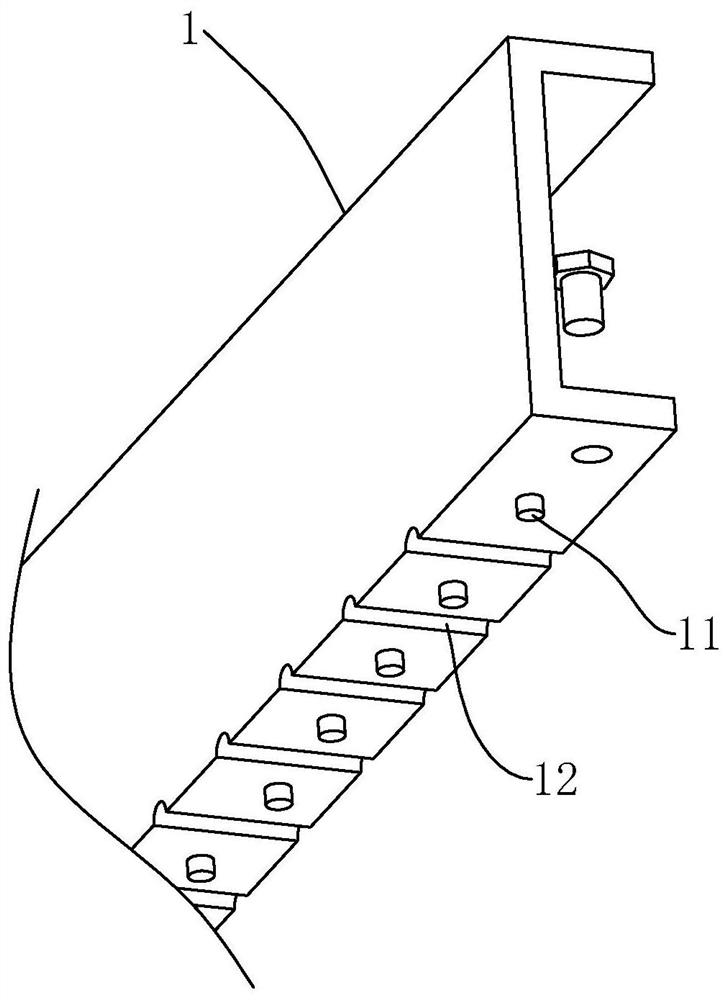

[0051] Step S3: see figure 2 , build form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com