Method applying wireless electric power transmission and magnetic force transmission on superconductive motor

A technology for wireless power transmission and superconducting motors, applied in the fields of superconducting motors and high-temperature superconducting motors, can solve the problems of increasing motor cooling costs and system complexity, increasing system heat leakage, increasing system sealing, etc., and reducing refrigeration. System cost and motor operating cost, small size, and the effect of optimized structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

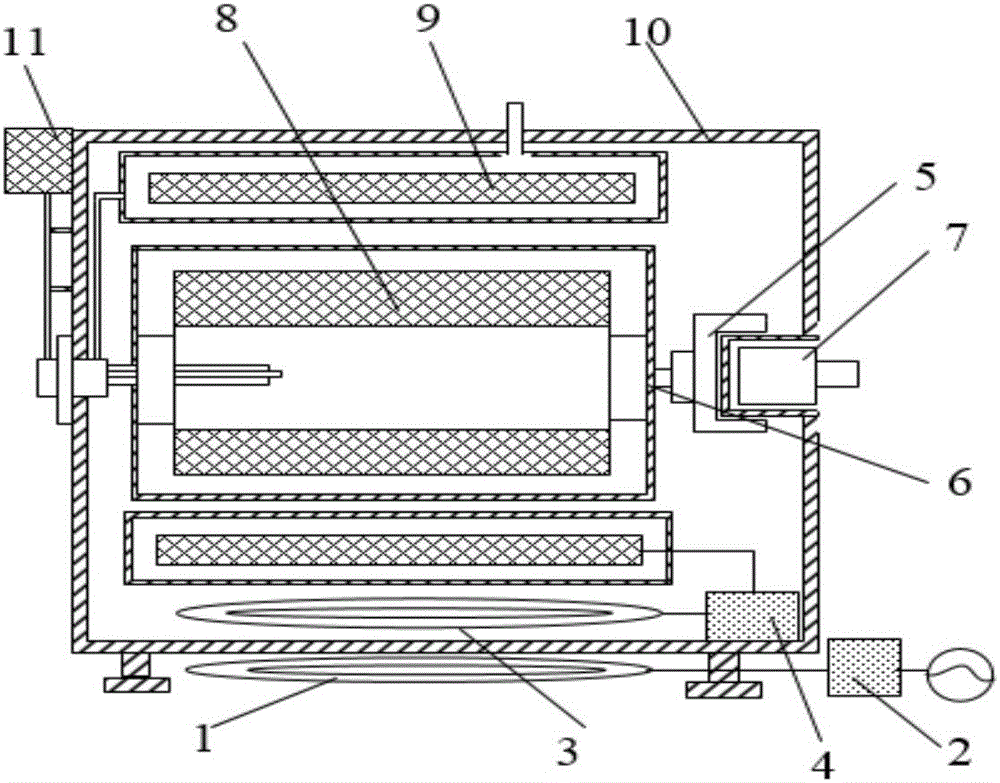

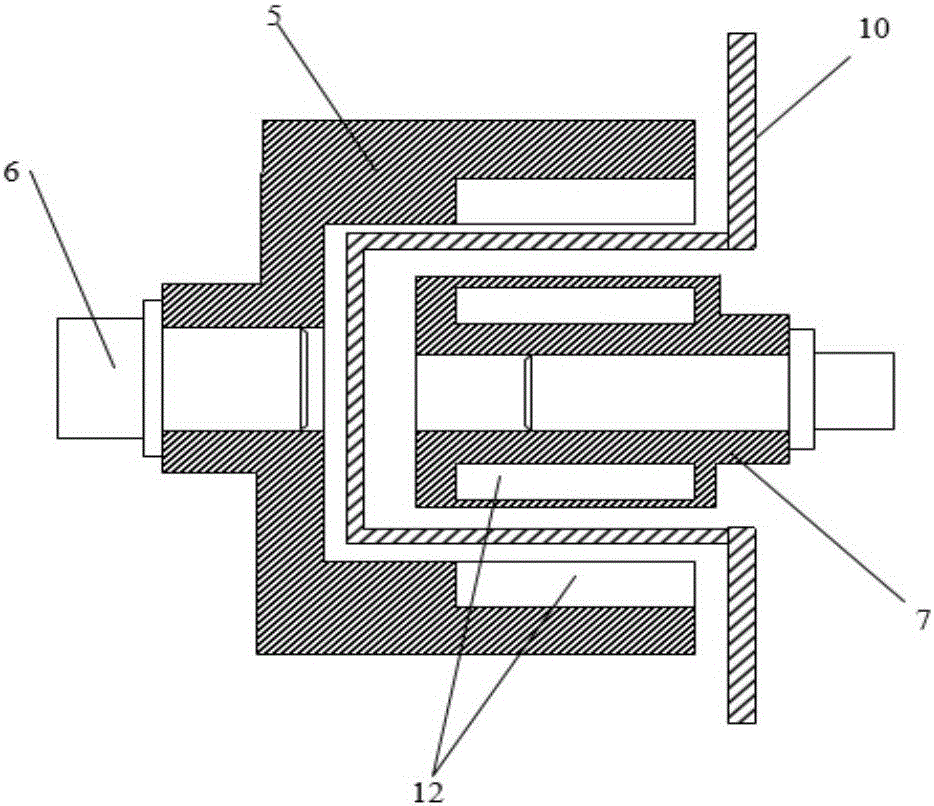

[0016] Such as figure 1 , 2 As shown, a method of applying wireless power transmission and magnetic transmission technology to a superconducting motor includes connecting the wireless power transmission device with the motor stator 9, and the magnetic transmission device is connected with the motor rotor 8 driving shaft, which is characterized in that: The transmitting coil 1 of the wireless power transmission device is connected to the frequency converter 2 and the industrial frequency power supply, and placed outside the motor, and the receiving coil 3 is connected to the winding of the motor stator 9 through the rectification and inverter unit 4, and placed in the outer Dewar 10; the magnetic transmission The device includes an inner rotor 7 and an outer rotor 5. The outer rotor 5 is connected to the motor driving shaft 6. The inner rotor 7 is connected to the load end.

[0017] The outer circumference of the inner rotor 7 of the magnetic transmission device and the magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com