Radiation damage monitoring method for nuclear power plant reactor pressure vessel

A technology for nuclear power plant reactors and pressure vessels, applied in the field of nuclear power, can solve the problems of high security requirements, high transportation costs, limited number of irradiation supervision tubes, etc., and achieve the effect of good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

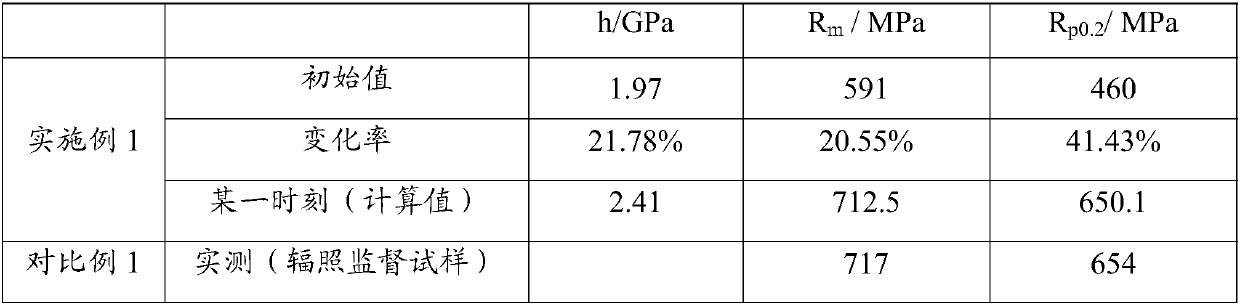

[0046] A nuclear power plant reactor pressure vessel radiation damage monitoring method, which comprises the following steps:

[0047] S1. Establish benchmarks: After the reactor pressure vessel is installed in place and before the first fueling operation of the nuclear power plant, use a portable nanoindentation instrument to measure the initial nanoindentation hardness h of the steel in the core area of the reactor pressure vessel 0 It is 1.97GPa; other methods can also be used to measure the initial nanoindentation hardness h of the reactor pressure vessel 0 , and the monitoring site can be artificially selected according to needs.

[0048] S2. Real-time monitoring: When the nuclear power plant is shut down for refueling maintenance, the nano-indentation hardness h of the same position after the radiation damage of the reactor pressure vessel is measured by a portable nano-indentation instrument is 2.41GPa; other conventional methods can also be used to measure the reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com