Stop valve for air conditioner and its processing method

A technology for stop valves and air conditioners, which is applied in the direction of lift valves, valve details, valve devices, etc., can solve the problems of difficult processing, insufficient valve main parts, and failure to put aluminum or aluminum alloy valves into production, so as to reduce raw material costs and reduce Environmental pollution, beneficial to the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] FIG. 1 is a structural schematic diagram of a globe valve adopting an integral forging structure in the prior art. The overall forging structure is a common structure and processing technology for copper material globe valves, but this overall structure processing technology is relatively difficult, and it is not suitable for aluminum and steel materials.

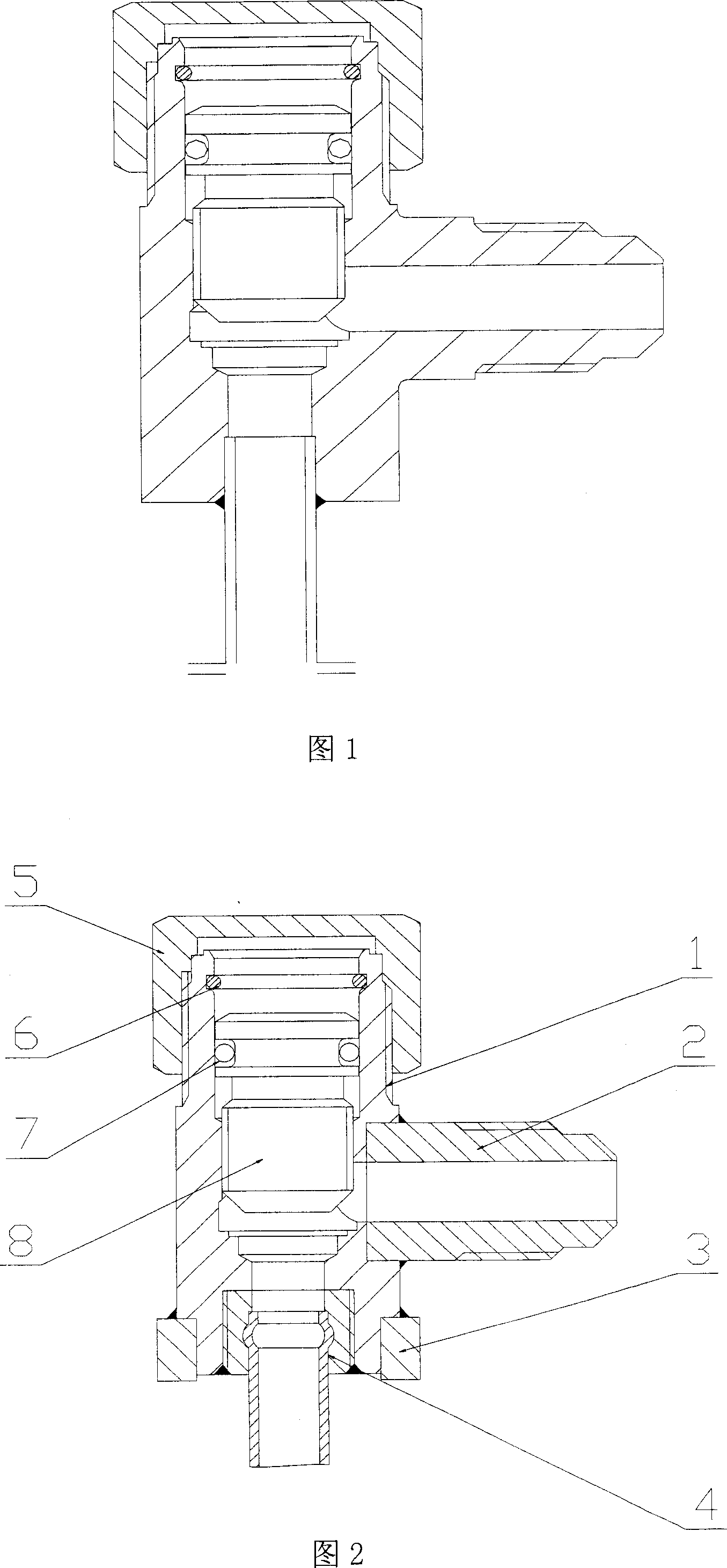

[0020] Figure 2 is a schematic structural view of the aluminum alloy split globe valve in the present invention. Its main parts are different from the prior art products, and are mainly composed of split valve body 1, joint 2, flange 3, and copper pipe 4. The above-mentioned parts are made of high-strength aluminum alloy, and then threaded The connection is combined with welding or direct welding, which simplifies the processing technology of the product. As a preference, the valve body 1, the joint 2 and the flange 3 are processed by aluminum alloy profiles such as round and square. Forging, casting and other proc...

Embodiment 2

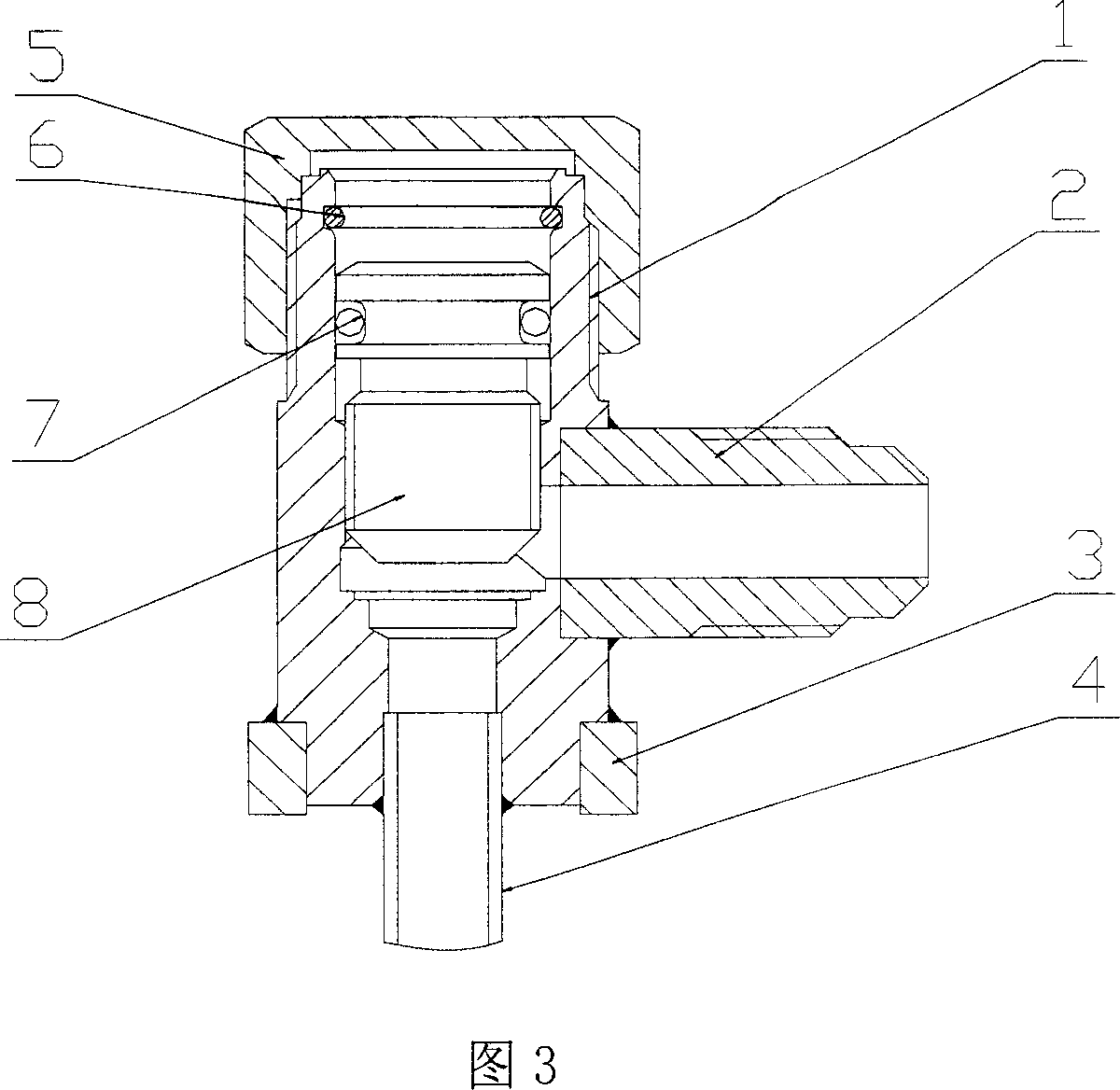

[0022] FIG. 3 is a schematic structural diagram of a steel material split globe valve in the present invention. Its main parts are different from the existing technical products, mainly composed of split valve body 1, joint 2, flange 3, and copper pipe 4. The above parts are made of free-cutting steel. On the premise of ensuring product strength , which can meet the processing requirements of the product; each component adopts welding combination, which obviously simplifies the processing technology of the product. The valve body 1, the joint 2 and the flange 3 are processed with round and square steel profiles or plates, and the raw materials are easy to prepare; completely avoiding the forging, casting and other processes required for the overall steel valve, simplifying the production equipment, simplifying the process, The process is simplified and fully meets the needs of mass production. The valve body 1 and the copper pipe 4 are connected by welding. This embodiment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com