Methods for monitoring and evaluating radiation damage of reactor pressure vessel steel in nuclear power plants

A technology for pressure vessels and radiation damage, which is applied in the field of nuclear power, can solve the problems of large amount of three wastes, long cycle, and inability to fully meet the requirements of radiation supervision, etc., and achieve the effect of real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

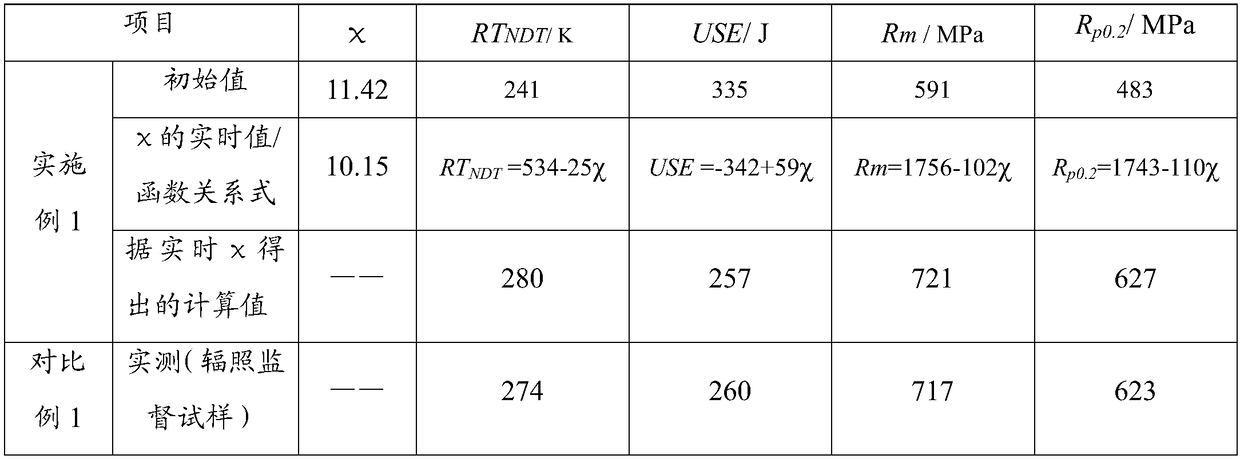

Embodiment 1

[0045] A method for monitoring and evaluating radiation damage of reactor pressure vessel steel in a nuclear power plant, comprising the following steps:

[0046] The initial magnetic susceptibility (χ) of the monitoring part of the reactor pressure vessel steel was measured before the first fueling operation of the nuclear power plant 初始 = 11.42, and query and record the non-ductile transition temperature (RT NDT ) 初始 =241K, upper platform energy (USE) 初始 =335J, tensile strength (R m ) 初始 =483MPa and yield strength (R p0.2 ) 初始 =591 MPa.

[0047] S1. Determination of safety threshold: determine and record the upper critical value of the non-ductile transition temperature of the reactor pressure vessel (RT NDT ) 上限 = 366K and Upper Platform Energy Lower Limit Critical Value (USE) 下限 = 68J.

[0048] The specific value of the above critical threshold depends on the nuclear safety regulations of the country where the monitored nuclear power plant is located, the nuclear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com