Steam turbine blade online damage state assessment system and steam turbine blade life assessment method

A technology for steam turbine blade and condition evaluation, which is applied in the direction of machine/engine, mechanical equipment, engine function, etc., can solve the high-cycle fatigue of high-temperature blades, low-cycle fatigue and low-temperature blade water erosion, fouling and wear evaluation, and blade online life evaluation. Inaccuracy and other problems, to avoid time and economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

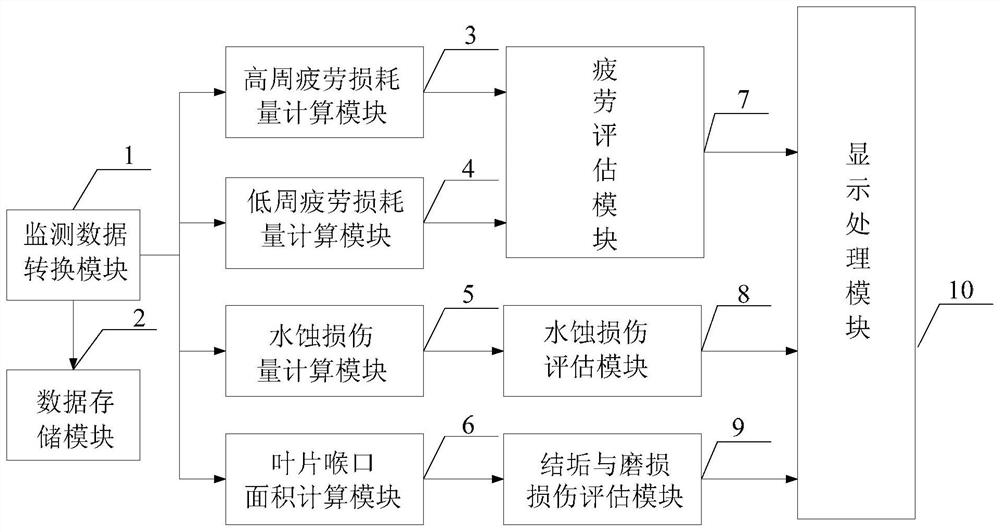

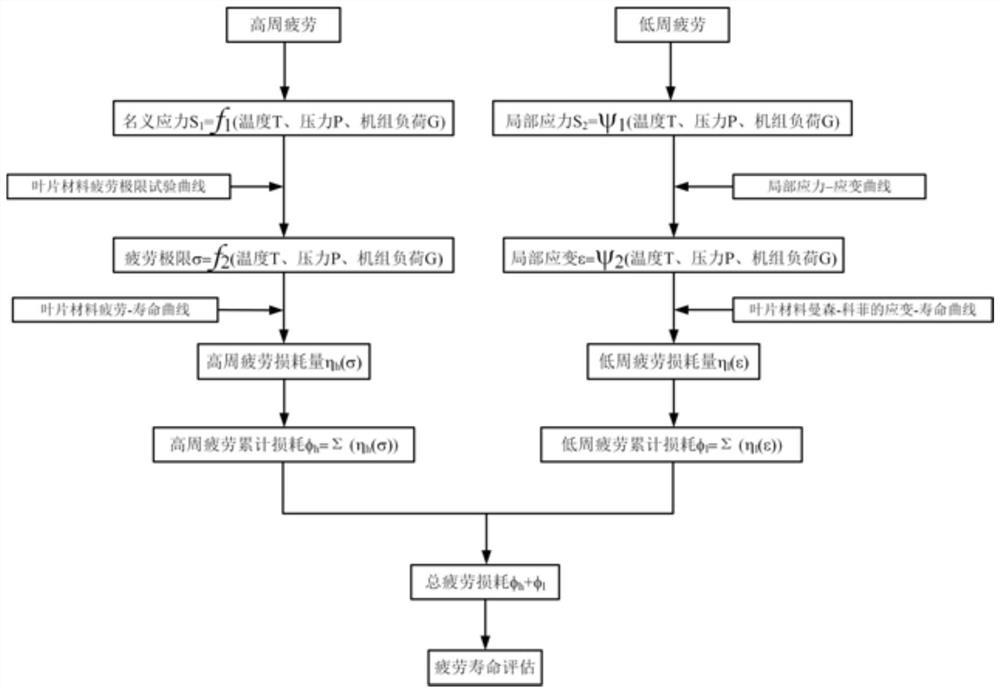

[0046] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the steam turbine blade online damage state evaluation system described in this embodiment,

[0047] The system includes a monitoring data conversion module (1), a high-cycle fatigue loss calculation module (3), a low-cycle fatigue loss calculation module (4), a water erosion damage calculation module (5), and a blade throat area calculation module (6 ), fatigue assessment module (7), water erosion damage assessment module (8) and fouling and wear damage assessment module (9);

[0048] The monitoring data conversion module (1) is used to receive the real-time parameter signal of the steam turbine blade monitored by the power plant, perform analog-to-digital conversion on the real-time parameter signal of the steam turbine blade, and send the real-time parameter signal of the steam turbine blade in digital form to the high-cycle fatigue loss calculation module (3), low cycle f...

specific Embodiment approach 2

[0058] Specific implementation mode two: the following combination figure 2 Describe this embodiment, this embodiment will further explain the steam turbine blade online damage state assessment system described in Embodiment 1, the system also includes a data storage module (2), and the data storage module (2) is used to receive and monitor The data conversion module (1) sends real-time parameter signals of steam turbine blades in digital form, and stores the received signals.

specific Embodiment approach 3

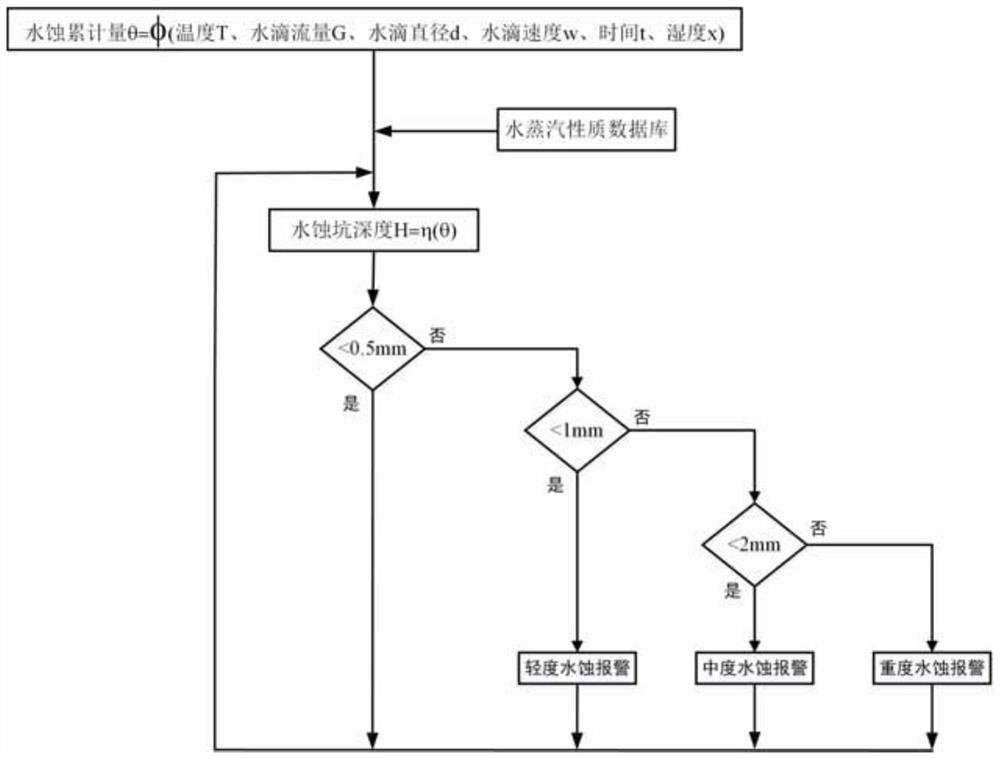

[0059] Specific embodiment three: this embodiment further explains the online damage state assessment system for steam turbine blades described in embodiment one, the system also includes a display processing module (10), and the display processing module (10) is used to receive fatigue evaluation The blade total fatigue loss signal of module (7) compares the received blade total fatigue loss with the steam turbine blade design fatigue loss threshold, when the blade total fatigue loss is greater than the steam turbine blade design fatigue loss threshold, Send fatigue warning signal, and display the warning signal and fatigue loss information;

[0060] It is also used for receiving mild, moderate or severe water erosion alarm signals sent by the water erosion damage assessment module (8), and displaying the received water erosion alarm signals;

[0061] It is also used to receive the steam turbine blade scaling alarm signal sent by the scaling and wear damage evaluation module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com