Fiberglass bending stress damage map quantitative evaluation method based on empirical mode decomposition

An empirical mode decomposition and quantitative evaluation technology, which is applied in the field of acoustic emission non-destructive testing, can solve problems such as the inability to detect FRP in service and the inability to assess the health status, and achieve the effect of a simple sound wave propagation path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

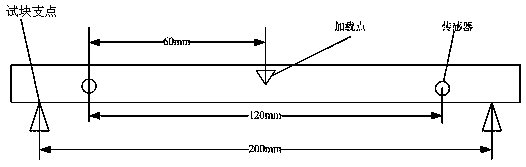

[0031] In the experiment, the acoustic emission detector was used to monitor the mechanical behavior of the FRP test block under the bending load in real time, and the damage phenomenon of the FRP under the bending load and the internal relationship with the characteristics of the acoustic emission signal were found, and based on this, The damage of FRP is quantitatively evaluated, and the specific implementation method is as follows:

[0032] The FRP test block is prepared, the test block matrix is made of 430 resin, and the woven glass fiber cloth is used as the reinforcing fiber. The design and manufacture of the test block refer to "GB / T1446-2005 General Rules for Test Methods of Fiber Reinforced Plastics". The test piece is a [0° / 90°] laminate with a thickness of 11mm. The specific dimensions are shown in Figure 1, where L is the length of the test block, b is the width of the test block, and h is the thickness of the test block. Referring to the national standard siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com