Buried oil pipeline external-corrosion real-time monitoring device based on optical fiber sensor

A technology of real-time monitoring and external corrosion, applied in the field of sensing and detection, can solve the problems of time trend prediction not meeting actual needs, increasing the risk of pipeline failure, and finding delay problem points, etc., to achieve compact structure, simple structure, and accurate location judgment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

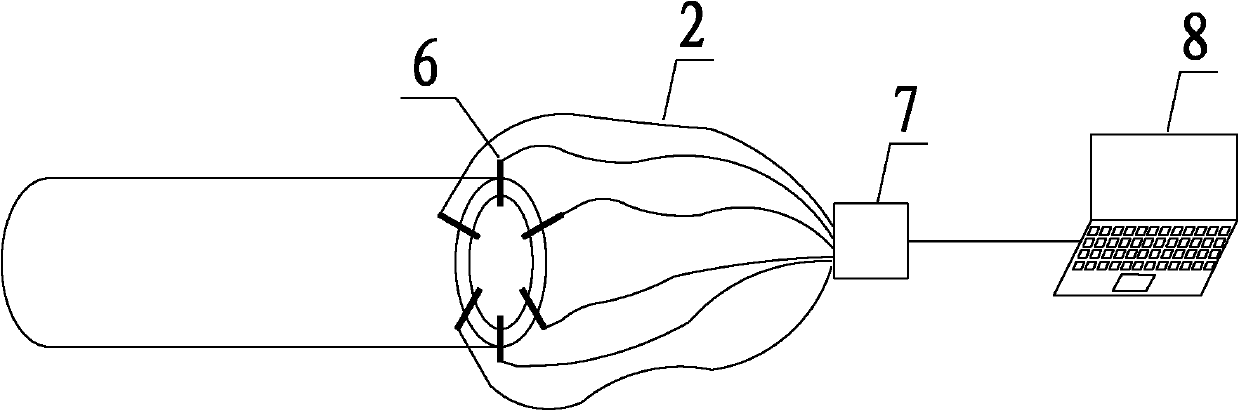

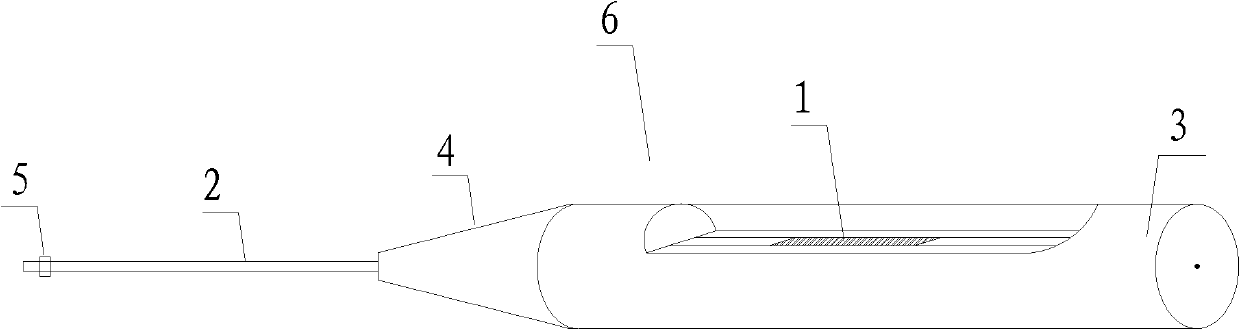

[0024] A real-time monitoring device for external corrosion of buried oil and gas pipelines based on optical fiber sensing, including a computer 8, a spectrum demodulator 7 and a blazed fiber grating sensor 6. The computer 8 is connected with the spectrum demodulator 7, and the spectrum demodulator 7 is connected with the blazed fiber grating sensor 6; In the needle-shaped housing 3, there is a single-mode optical fiber 2 connected to the spectrum demodulator in the needle-shaped housing 3, and a protective sleeve 4 is installed at the end of the needle-shaped housing. The needle-shaped shell is in the shape of a semi-circular barrel at the place where the blazed fiber grating is assembled. When the blazed fiber grating sensor monitors in real time, the blazed fiber grating sensor is radially distributed around the buried oil and gas pipeline.

[0025] Concrete structure and working process of the present embodiment:

[0026] The real-time monitoring device for pipeline exte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com